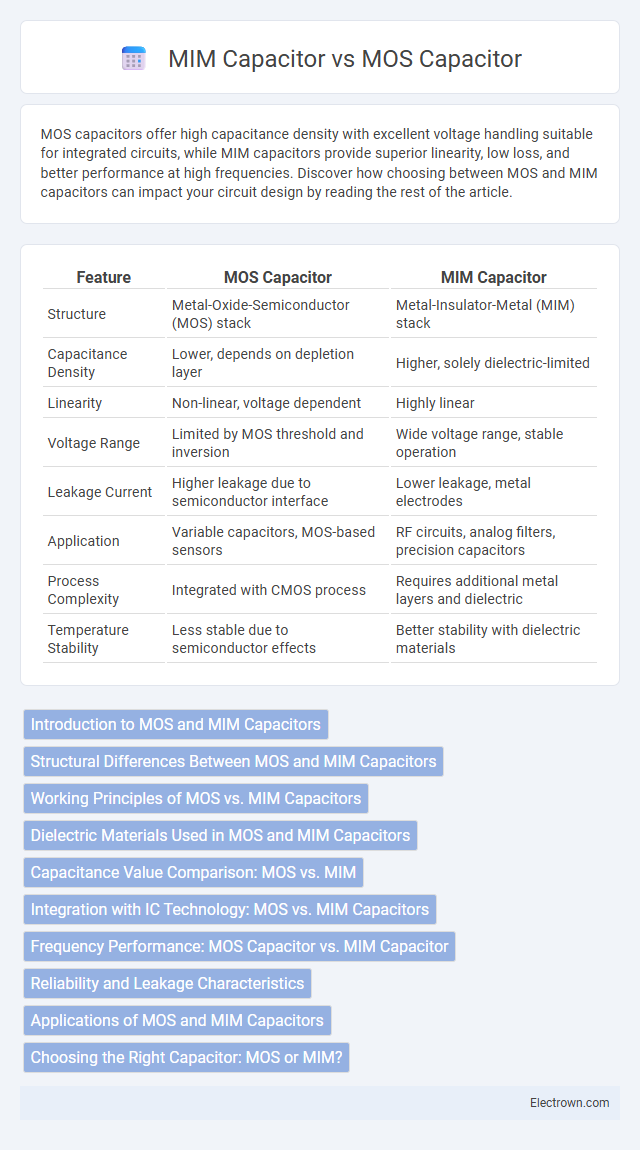

MOS capacitors offer high capacitance density with excellent voltage handling suitable for integrated circuits, while MIM capacitors provide superior linearity, low loss, and better performance at high frequencies. Discover how choosing between MOS and MIM capacitors can impact your circuit design by reading the rest of the article.

Table of Comparison

| Feature | MOS Capacitor | MIM Capacitor |

|---|---|---|

| Structure | Metal-Oxide-Semiconductor (MOS) stack | Metal-Insulator-Metal (MIM) stack |

| Capacitance Density | Lower, depends on depletion layer | Higher, solely dielectric-limited |

| Linearity | Non-linear, voltage dependent | Highly linear |

| Voltage Range | Limited by MOS threshold and inversion | Wide voltage range, stable operation |

| Leakage Current | Higher leakage due to semiconductor interface | Lower leakage, metal electrodes |

| Application | Variable capacitors, MOS-based sensors | RF circuits, analog filters, precision capacitors |

| Process Complexity | Integrated with CMOS process | Requires additional metal layers and dielectric |

| Temperature Stability | Less stable due to semiconductor effects | Better stability with dielectric materials |

Introduction to MOS and MIM Capacitors

MOS capacitors utilize a metal-oxide-semiconductor structure where the oxide layer serves as the dielectric, commonly employed in integrated circuits for high capacitance density and voltage control applications. MIM capacitors consist of two metal layers separated by an insulating dielectric, offering superior linearity, high-quality factor (Q), and stable capacitance over frequency, ideal for RF and analog circuits. Both capacitor types play critical roles in semiconductor device fabrication, with MOS capacitors favored for interface characterization and MIM capacitors preferred for high-performance passive components.

Structural Differences Between MOS and MIM Capacitors

MOS and MIM capacitors differ fundamentally in their structure; MOS capacitors use a metal-oxide-semiconductor stack where a thin oxide layer separates the metal gate from the semiconductor substrate, enabling charge storage in the depletion region. MIM capacitors consist of two metal plates separated by a high-k dielectric layer, providing higher capacitance density and better linearity compared to MOS capacitors. Understanding these structural differences is crucial when selecting the right capacitor for your integrated circuit design, as they impact performance, leakage, and fabrication complexity.

Working Principles of MOS vs. MIM Capacitors

MOS capacitors operate by forming a depletion region at the metal-oxide-semiconductor interface when voltage is applied, modulating the capacitance based on the charge distribution in the semiconductor. MIM capacitors consist of two metal layers separated by a dielectric, providing a stable and linear capacitance primarily determined by the dielectric constant and physical dimensions. Your choice depends on the desired capacitance stability and application frequency, with MOS capacitors offering voltage-dependent capacitance and MIM capacitors delivering consistent performance.

Dielectric Materials Used in MOS and MIM Capacitors

MOS capacitors utilize a thin layer of silicon dioxide (SiO2) as the primary dielectric material, which offers excellent interface quality and low leakage current suitable for semiconductor applications. MIM capacitors employ high-k dielectric materials such as hafnium oxide (HfO2) or aluminum oxide (Al2O3), providing higher capacitance density and better reliability for advanced integrated circuits. Understanding these dielectric differences helps you select the right capacitor type based on capacitance requirements and integration complexity.

Capacitance Value Comparison: MOS vs. MIM

MOS capacitors typically exhibit lower capacitance values due to their thinner oxide layers and parasitic effects, often ranging from a few femtofarads to picofarads. MIM capacitors provide higher capacitance density with values frequently in the tens to hundreds of picofarads, achieved through high-quality metal-insulator-metal layers. Your choice depends on the required capacitance level and linearity, favoring MIM capacitors for applications demanding stable, high capacitance.

Integration with IC Technology: MOS vs. MIM Capacitors

MOS capacitors offer superior integration with standard CMOS IC technology due to their direct fabrication within the transistor process, enabling seamless on-chip implementation without additional steps. MIM capacitors, while providing higher capacitance density and better linearity, often require specialized layers or modules that may complicate integration and increase manufacturing complexity. Your choice between MOS and MIM capacitors depends on the balance between ease of integration and performance requirements within the IC design.

Frequency Performance: MOS Capacitor vs. MIM Capacitor

MOS capacitors exhibit limited frequency performance due to interface states and oxide traps causing dispersion at high frequencies, making them less suitable for microwave applications. MIM capacitors demonstrate superior frequency response with low loss and stable capacitance up to GHz frequencies, attributed to their metal-insulator-metal structure minimizing parasitic effects. This makes MIM capacitors ideal for RF and high-frequency analog circuits requiring precise and stable capacitive behavior.

Reliability and Leakage Characteristics

MOS capacitors exhibit higher leakage currents due to the thin oxide layer, which can degrade reliability under high electric fields and temperature stress. MIM capacitors feature metal-insulator-metal structures with thicker, high-quality dielectric layers that provide superior leakage performance and enhanced reliability in demanding applications. The intrinsic design differences make MIM capacitors preferable for low-leakage, stable operation in advanced analog and RF circuits.

Applications of MOS and MIM Capacitors

MOS capacitors are widely used in integrated circuits for analog and digital applications such as voltage-controlled oscillators, filters, and memory cells due to their compatibility with standard CMOS processes and variable capacitance properties. MIM capacitors excel in RF and high-frequency applications, offering superior linearity, low parasitic inductance, and high capacitance density, making them ideal for RF filters, ADCs, and precision analog circuits. Understanding the distinct applications of MOS and MIM capacitors helps you select the best component for your specific electronic design requirements.

Choosing the Right Capacitor: MOS or MIM?

Choosing the right capacitor depends on your circuit's performance requirements and space constraints. MOS capacitors offer high capacitance density and are ideal for integrated circuits with limited area, while MIM capacitors provide superior linearity, low leakage, and excellent high-frequency stability, making them suitable for RF and precision analog applications. Evaluate your design's voltage range, frequency response, and noise tolerance to determine whether a MOS or MIM capacitor best suits your needs.

mos capacitor vs mim capacitor Infographic

electrown.com

electrown.com