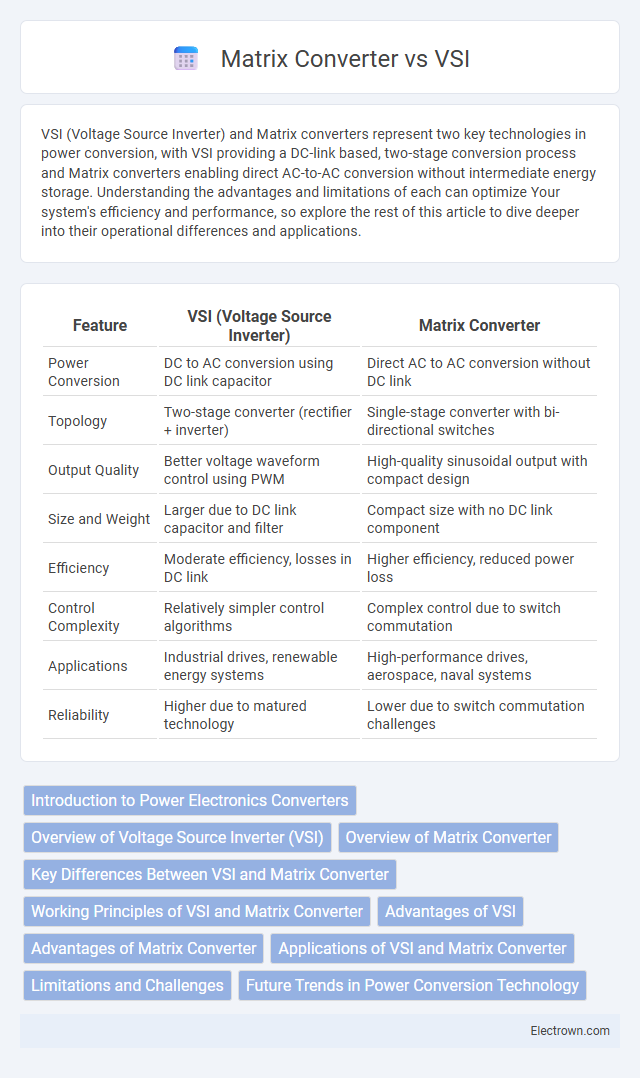

VSI (Voltage Source Inverter) and Matrix converters represent two key technologies in power conversion, with VSI providing a DC-link based, two-stage conversion process and Matrix converters enabling direct AC-to-AC conversion without intermediate energy storage. Understanding the advantages and limitations of each can optimize Your system's efficiency and performance, so explore the rest of this article to dive deeper into their operational differences and applications.

Table of Comparison

| Feature | VSI (Voltage Source Inverter) | Matrix Converter |

|---|---|---|

| Power Conversion | DC to AC conversion using DC link capacitor | Direct AC to AC conversion without DC link |

| Topology | Two-stage converter (rectifier + inverter) | Single-stage converter with bi-directional switches |

| Output Quality | Better voltage waveform control using PWM | High-quality sinusoidal output with compact design |

| Size and Weight | Larger due to DC link capacitor and filter | Compact size with no DC link component |

| Efficiency | Moderate efficiency, losses in DC link | Higher efficiency, reduced power loss |

| Control Complexity | Relatively simpler control algorithms | Complex control due to switch commutation |

| Applications | Industrial drives, renewable energy systems | High-performance drives, aerospace, naval systems |

| Reliability | Higher due to matured technology | Lower due to switch commutation challenges |

Introduction to Power Electronics Converters

Power electronics converters play a crucial role in efficiently transforming electrical energy, with Voltage Source Inverters (VSI) and Matrix Converters representing two prominent types. VSIs use energy storage elements like capacitors to provide a stable DC voltage, offering output waveforms suitable for motor drives and renewable energy systems. Matrix converters eliminate bulky energy storage by directly converting AC to AC with bidirectional switches, making your power conversion system more compact and reliable.

Overview of Voltage Source Inverter (VSI)

Voltage Source Inverter (VSI) is a power electronic device that converts DC voltage into a variable AC voltage with adjustable frequency, widely used in motor drives and renewable energy systems. VSI features a DC voltage input source and a transistor-based switching network, enabling efficient control of output voltage amplitude and frequency through pulse width modulation (PWM) techniques. Its ability to provide stable voltage output and high switching frequency improves power quality and system dynamic response compared to Matrix Converters.

Overview of Matrix Converter

Matrix converters offer a direct AC-AC conversion without the need for intermediate DC links, enabling compact design and improved efficiency. They utilize an array of bidirectional switches to directly connect input phases to output phases, allowing for continuous voltage and frequency control. This topology reduces component count and enhances system reliability compared to traditional Voltage Source Inverters (VSIs).

Key Differences Between VSI and Matrix Converter

Voltage Source Inverters (VSI) use a DC link capacitor to convert DC input into AC output, providing stable voltage waveforms, whereas Matrix Converters directly convert AC input to AC output without energy storage elements, enhancing compactness and efficiency. VSIs typically offer easier control and better fault tolerance, while Matrix Converters excel in bidirectional power flow and regenerative braking capabilities. Your choice depends on application requirements like size constraints, power quality, and dynamic performance.

Working Principles of VSI and Matrix Converter

Voltage Source Inverters (VSI) operate by converting a DC voltage source into AC output through switching devices that control the output voltage and frequency, enabling precise motor speed control. Matrix converters directly transform AC input to AC output without an intermediate DC link by using an array of bidirectional switches, allowing seamless input-output frequency and amplitude variation. Your choice between VSI and matrix converter depends on the application's requirements for efficiency, size, and power quality.

Advantages of VSI

Voltage Source Inverters (VSI) offer superior efficiency and simpler control compared to Matrix Converters, making them ideal for variable speed drive applications. VSI systems provide robust performance with well-established modulation techniques like PWM, ensuring precise voltage and frequency control for optimal motor operation. Your choice of VSI enhances reliability and reduces complexity, leading to easier maintenance and lower overall costs.

Advantages of Matrix Converter

Matrix converters offer several advantages over traditional Voltage Source Inverters (VSI), including a compact design with fewer passive components, resulting in reduced size and weight. They provide bidirectional power flow and allow direct AC-to-AC conversion without an intermediate DC link, enhancing efficiency and power density. Matrix converters also enable a wider range of output voltage and frequency control, improving the dynamic performance and flexibility in variable-speed drive applications.

Applications of VSI and Matrix Converter

Voltage Source Inverters (VSI) are widely used in applications such as adjustable speed drives, renewable energy systems, and uninterruptible power supplies due to their ability to efficiently convert DC to AC with high control accuracy. Matrix Converters, on the other hand, find applications in aerospace, electric vehicles, and industrial motor drives where direct AC-to-AC conversion with compact size and bidirectional power flow is crucial. Your choice between VSI and Matrix Converter depends on factors like system complexity, space constraints, and the need for input power quality improvement.

Limitations and Challenges

Voltage Source Inverters (VSI) face limitations including harmonic distortion, switching losses, and reliance on bulky DC link capacitors, which affect overall efficiency and reliability. Matrix converters encounter challenges such as complex control algorithms, inability to provide galvanic isolation, and limited switching device options, making thermal management and fault protection more difficult. Both technologies require careful design considerations to mitigate electromagnetic interference and ensure stable operation under varying load conditions.

Future Trends in Power Conversion Technology

Future trends in power conversion technology emphasize higher efficiency and improved reliability in both VSI (Voltage Source Inverter) and matrix converters, with advancements in wide-bandgap semiconductors such as SiC and GaN driving reduced switching losses and higher operating frequencies. Matrix converters offer compact designs and bi-directional power flow without bulky DC-link components, making them promising for compact and flexible applications, while VSI systems continue to dominate in cost-effectiveness and mature industry adoption. Your choice between these technologies will depend on evolving demands for power density, efficiency, and integration in renewable energy and electric vehicle sectors.

VSI vs Matrix converter Infographic

electrown.com

electrown.com