Thermal pads efficiently transfer heat away from electronic components to prevent overheating, while insulating pads primarily block heat to protect sensitive areas. Understanding the differences between these two materials can help you choose the right solution for your device's thermal management needs--read on to explore their unique properties and applications.

Table of Comparison

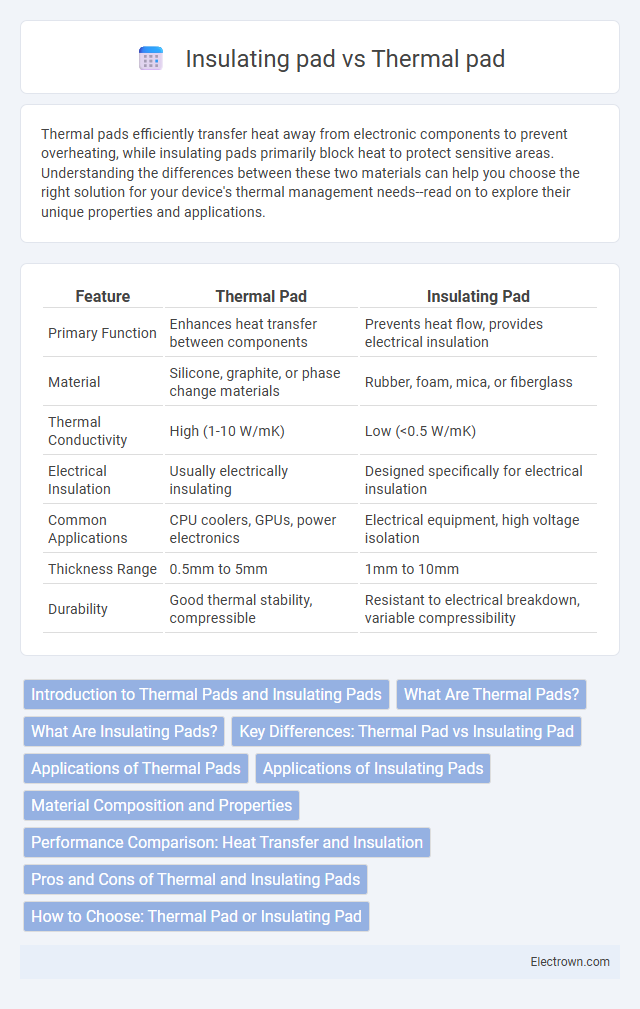

| Feature | Thermal Pad | Insulating Pad |

|---|---|---|

| Primary Function | Enhances heat transfer between components | Prevents heat flow, provides electrical insulation |

| Material | Silicone, graphite, or phase change materials | Rubber, foam, mica, or fiberglass |

| Thermal Conductivity | High (1-10 W/mK) | Low (<0.5 W/mK) |

| Electrical Insulation | Usually electrically insulating | Designed specifically for electrical insulation |

| Common Applications | CPU coolers, GPUs, power electronics | Electrical equipment, high voltage isolation |

| Thickness Range | 0.5mm to 5mm | 1mm to 10mm |

| Durability | Good thermal stability, compressible | Resistant to electrical breakdown, variable compressibility |

Introduction to Thermal Pads and Insulating Pads

Thermal pads are designed to enhance heat transfer between electronic components and heat sinks, typically composed of materials with high thermal conductivity such as silicone infused with ceramic particles. Insulating pads serve primarily to electrically isolate components while providing moderate thermal conductivity, often made from materials like mica or polymer composites. Both pads play crucial roles in managing thermal performance and electrical safety in electronic assemblies.

What Are Thermal Pads?

Thermal pads are specialized materials designed to facilitate efficient heat transfer between electronic components and heat sinks, preventing overheating and ensuring device longevity. These pads typically feature high thermal conductivity and electrical insulation properties, making them essential for managing device temperatures without causing electrical short circuits. Choosing the right thermal pad enhances your hardware's performance by maintaining optimal thermal regulation.

What Are Insulating Pads?

Insulating pads are materials designed to prevent heat transfer, protecting sensitive components from excessive temperatures by providing electrical insulation and thermal resistance. These pads typically consist of silicone or other polymers with void-free, thermally conductive fillers that enhance heat dissipation while maintaining electrical isolation. Unlike thermal pads that primarily facilitate heat transfer between components and heat sinks, insulating pads focus on ensuring electrical safety and preventing short circuits in electronic assemblies.

Key Differences: Thermal Pad vs Insulating Pad

Thermal pads are designed to conduct heat efficiently away from electronic components, enhancing cooling performance, while insulating pads primarily prevent electrical conductivity and protect against short circuits. Thermal pads typically feature higher thermal conductivity materials such as silicone or graphite composites, whereas insulating pads use materials like rubber or foam that resist heat transfer. Understanding these key differences helps you select the right pad to manage heat dissipation or electrical insulation in your electronic devices.

Applications of Thermal Pads

Thermal pads are widely used in electronics for heat dissipation between components and heat sinks, ensuring optimal thermal conductivity and preventing overheating in devices such as CPUs, GPUs, and power electronics. Their ability to conform to uneven surfaces makes them ideal for applications requiring both electrical insulation and efficient heat transfer, such as LED lighting modules and automotive control units. In contrast, insulating pads primarily focus on electrical insulation and mechanical protection, with limited thermal conductivity, making them less suitable for high-performance thermal management tasks.

Applications of Insulating Pads

Insulating pads are widely used in electrical and electronic applications to prevent heat transfer and protect sensitive components from thermal damage. These pads provide electrical insulation while maintaining high thermal conductivity, making them ideal for heat sinks, power modules, and circuit boards. Their ability to withstand high temperatures and electrical stress ensures reliable performance in automotive, industrial, and consumer electronics sectors.

Material Composition and Properties

Thermal pads are typically made from silicone or other polymer-based compounds infused with thermally conductive fillers like ceramic or metal oxides, designed to efficiently transfer heat away from sensitive electronic components. Insulating pads prioritize electrical insulation and are often composed of materials such as mica, fiberglass, or silicone rubber with minimal thermal conductivity to prevent electrical currents from passing through. Your choice between these pads depends on whether heat dissipation or electrical isolation is the primary requirement for your application.

Performance Comparison: Heat Transfer and Insulation

Thermal pads exhibit superior heat transfer capabilities due to their high thermal conductivity, effectively dissipating heat from electronic components to heat sinks. Insulating pads prioritize electrical isolation over thermal performance, featuring low thermal conductivity that limits heat flow but enhances protection against electrical shorts. For applications demanding efficient heat dissipation, thermal pads outperform insulating pads, whereas insulating pads are ideal for scenarios requiring electrical insulation with minimal heat transfer.

Pros and Cons of Thermal and Insulating Pads

Thermal pads offer excellent heat transfer capabilities, making them ideal for cooling electronic components, but they may degrade over time and require precise application. Insulating pads provide strong electrical isolation and prevent short circuits, yet their thermal conductivity is generally lower, which can lead to overheating issues. Your choice depends on whether heat dissipation or electrical insulation is the primary concern in your application.

How to Choose: Thermal Pad or Insulating Pad

Choosing between a thermal pad and an insulating pad depends on your device's heat management needs and electrical isolation requirements. Thermal pads efficiently conduct heat away from electronic components, preventing overheating, while insulating pads focus on electrical insulation to protect against short circuits without significant heat transfer. Assess your system's thermal conductivity demands and electrical insulation needs to select the right pad that ensures optimal performance and safety.

Thermal pad vs Insulating pad Infographic

electrown.com

electrown.com