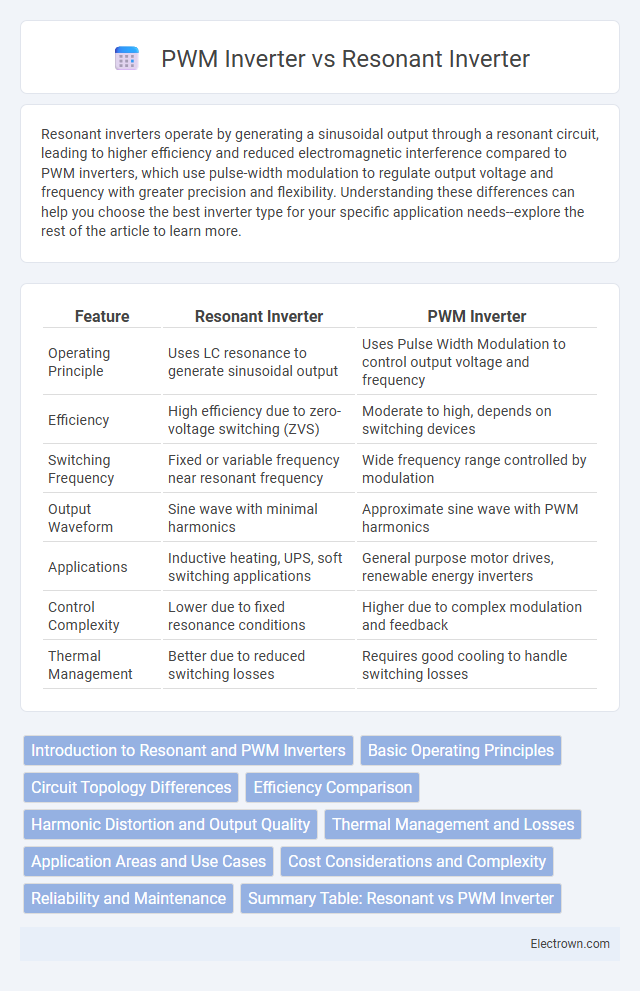

Resonant inverters operate by generating a sinusoidal output through a resonant circuit, leading to higher efficiency and reduced electromagnetic interference compared to PWM inverters, which use pulse-width modulation to regulate output voltage and frequency with greater precision and flexibility. Understanding these differences can help you choose the best inverter type for your specific application needs--explore the rest of the article to learn more.

Table of Comparison

| Feature | Resonant Inverter | PWM Inverter |

|---|---|---|

| Operating Principle | Uses LC resonance to generate sinusoidal output | Uses Pulse Width Modulation to control output voltage and frequency |

| Efficiency | High efficiency due to zero-voltage switching (ZVS) | Moderate to high, depends on switching devices |

| Switching Frequency | Fixed or variable frequency near resonant frequency | Wide frequency range controlled by modulation |

| Output Waveform | Sine wave with minimal harmonics | Approximate sine wave with PWM harmonics |

| Applications | Inductive heating, UPS, soft switching applications | General purpose motor drives, renewable energy inverters |

| Control Complexity | Lower due to fixed resonance conditions | Higher due to complex modulation and feedback |

| Thermal Management | Better due to reduced switching losses | Requires good cooling to handle switching losses |

Introduction to Resonant and PWM Inverters

Resonant inverters use oscillating circuits to convert DC to AC with high efficiency and reduced switching losses by operating at resonant frequency. PWM inverters employ pulse width modulation to regulate output voltage and frequency precisely, enabling better control over motor speed and power quality. Both technologies serve in power electronics but differ in switching techniques and application suitability.

Basic Operating Principles

Resonant inverters operate by generating sinusoidal waveforms using LC tank circuits that create resonance at a specific frequency, minimizing switching losses and electromagnetic interference. PWM (Pulse Width Modulation) inverters produce output voltage by rapidly switching semiconductor devices on and off, adjusting the pulse width to control the output waveform and voltage amplitude accurately. Resonant inverters excel in efficiency for high-frequency applications, whereas PWM inverters offer greater versatility in voltage and frequency control for various load conditions.

Circuit Topology Differences

Resonant inverters use LC tank circuits to achieve soft switching, minimizing switching losses and electromagnetic interference by operating at resonant frequencies. PWM inverters rely on semiconductor switches modulated by pulse-width signals to control output voltage and frequency with high precision but higher switching losses. Your choice depends on application needs for efficiency, noise reduction, and control complexity tied to these fundamental circuit topology differences.

Efficiency Comparison

Resonant inverters achieve higher efficiency by operating at zero voltage switching (ZVS) or zero current switching (ZCS), significantly reducing switching losses and electromagnetic interference compared to PWM inverters. PWM inverters typically experience greater switching losses due to hard switching, especially at higher frequencies, impacting overall power conversion efficiency. In applications demanding high-frequency operation and reduced thermal stress, resonant inverters outperform PWM inverters in energy efficiency and reliability.

Harmonic Distortion and Output Quality

Resonant inverters produce lower harmonic distortion compared to PWM inverters due to their soft-switching characteristics, resulting in smoother output waveforms and reduced electromagnetic interference. PWM inverters generate output by rapidly switching the transistors on and off, which can cause higher harmonic content and potential signal noise. Optimizing your system with a resonant inverter enhances output quality, providing cleaner power ideal for sensitive electronic equipment and improving overall efficiency.

Thermal Management and Losses

Resonant inverters offer superior thermal management due to lower switching losses, as their zero-voltage or zero-current switching minimizes heat generation. PWM inverters, while more common, experience higher switching losses and thus require more robust cooling systems to manage the increased thermal stress. Choosing the right inverter affects your system's efficiency and thermal performance, with resonant inverters providing a cooler and more energy-efficient operation.

Application Areas and Use Cases

Resonant inverters excel in high-frequency applications such as induction heating, wireless power transfer, and medical equipment due to their low switching losses and efficient soft switching capabilities. PWM inverters are widely used in renewable energy systems, motor drives, and uninterruptible power supplies (UPS) because of their precise voltage and frequency control and adaptability to varying load conditions. Industrial automation, electric vehicles, and power conditioning systems commonly leverage PWM inverters for superior dynamic response and higher efficiency in diverse operational environments.

Cost Considerations and Complexity

Resonant inverters typically exhibit higher initial costs due to specialized components and intricate design requirements, while PWM inverters offer more cost-effective solutions with widely available parts. The complexity of resonant inverters lies in precise frequency control and tuning to maintain resonance, increasing development and maintenance challenges. PWM inverters benefit from simpler control algorithms and easier scalability, reducing overall system complexity and operational costs.

Reliability and Maintenance

Resonant inverters offer higher reliability due to fewer switching losses and reduced electromagnetic interference, resulting in less thermal stress on components. PWM inverters require more frequent maintenance because their high switching frequencies generate greater heat, leading to accelerated wear of semiconductor devices. Your choice of inverter impacts maintenance schedules and system downtime, with resonant designs typically providing longer service intervals and lower operational costs.

Summary Table: Resonant vs PWM Inverter

A summary table highlights resonant inverters offering high efficiency, low switching losses, and reduced electromagnetic interference due to soft switching techniques. PWM inverters excel in precise output voltage and frequency control with widespread industrial use but suffer from higher switching losses and electromagnetic noise. Resonant inverters are ideal for high-frequency applications, while PWM inverters remain versatile for general-purpose motor drives and power conversion.

resonant inverter vs pwm inverter Infographic

electrown.com

electrown.com