PWM inverters deliver precise control of output voltage and frequency using pulse width modulation, ensuring high efficiency and smoother waveform quality suitable for sensitive electronic equipment. VSI (Voltage Source Inverter) focuses on providing a stable voltage source with fast dynamic response and robustness, commonly used in industrial motor drives and renewable energy systems; explore the rest of the article to understand which inverter best suits your specific application needs.

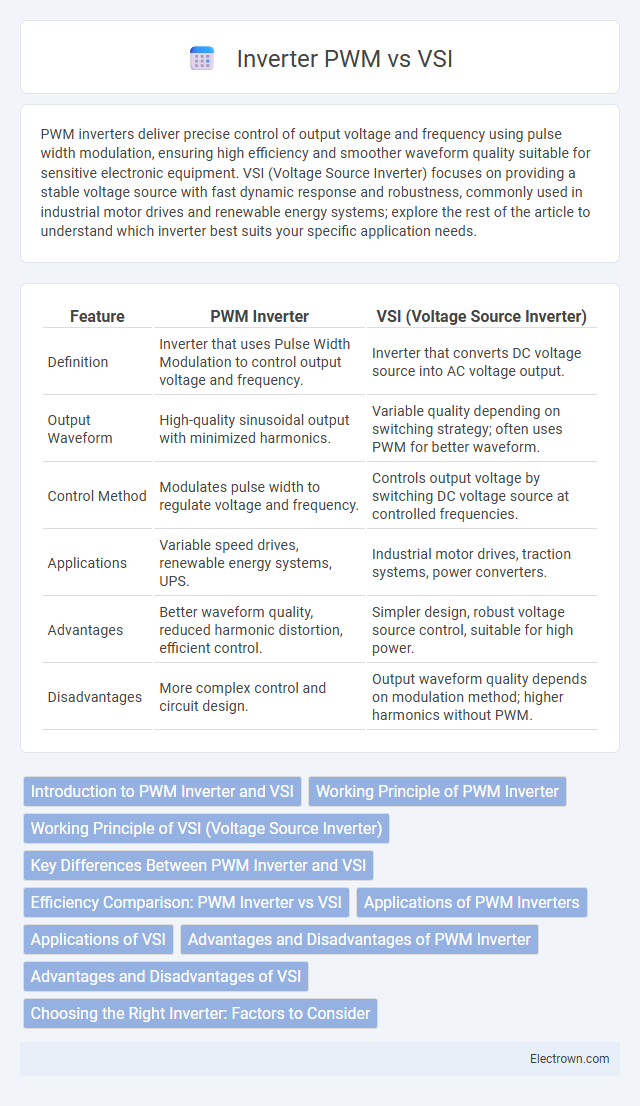

Table of Comparison

| Feature | PWM Inverter | VSI (Voltage Source Inverter) |

|---|---|---|

| Definition | Inverter that uses Pulse Width Modulation to control output voltage and frequency. | Inverter that converts DC voltage source into AC voltage output. |

| Output Waveform | High-quality sinusoidal output with minimized harmonics. | Variable quality depending on switching strategy; often uses PWM for better waveform. |

| Control Method | Modulates pulse width to regulate voltage and frequency. | Controls output voltage by switching DC voltage source at controlled frequencies. |

| Applications | Variable speed drives, renewable energy systems, UPS. | Industrial motor drives, traction systems, power converters. |

| Advantages | Better waveform quality, reduced harmonic distortion, efficient control. | Simpler design, robust voltage source control, suitable for high power. |

| Disadvantages | More complex control and circuit design. | Output waveform quality depends on modulation method; higher harmonics without PWM. |

Introduction to PWM Inverter and VSI

PWM inverters use pulse width modulation to control voltage and frequency, providing efficient power conversion with reduced harmonic distortion. Voltage Source Inverters (VSIs) supply a stable DC voltage input to generate AC output, commonly applied in renewable energy and motor drives. Understanding the differences between PWM inverters and VSIs helps optimize your power system's performance and reliability.

Working Principle of PWM Inverter

The working principle of a PWM inverter revolves around Pulse Width Modulation to convert DC voltage into a stable AC output by adjusting the width of voltage pulses. This modulation controls the output voltage and frequency, enabling efficient power delivery with reduced harmonic distortion. Your choice of a PWM inverter ensures precise control over motor speed and torque compared to a Voltage Source Inverter (VSI), which relies on constant voltage output without pulse width variations.

Working Principle of VSI (Voltage Source Inverter)

The working principle of a Voltage Source Inverter (VSI) involves converting a fixed DC voltage into a variable AC voltage by systematically switching its semiconductor devices like IGBTs or MOSFETs. This switching operation generates a sinusoidal output waveform with controlled frequency and amplitude, achieved through pulse width modulation (PWM) techniques. VSIs maintain a constant input voltage source while regulating output voltage and frequency, making them ideal for applications in motor drives and uninterruptible power supplies.

Key Differences Between PWM Inverter and VSI

PWM inverters use pulse width modulation to control voltage and frequency, enabling precise motor speed regulation and reduced harmonic distortion. VSI (Voltage Source Inverter) supplies a constant DC voltage source and generates AC output by switching devices in a controlled manner, often resulting in simpler designs but less harmonic control. Your choice depends on the need for precise waveform quality and motor performance requirements.

Efficiency Comparison: PWM Inverter vs VSI

PWM inverters typically offer higher efficiency than Voltage Source Inverters (VSIs) due to their advanced modulation techniques that reduce switching losses and improve power quality. The precise pulse control in PWM inverters enables better voltage regulation and minimizes harmonic distortion, leading to energy savings and enhanced system performance. Your choice of inverter should consider these efficiency differences to optimize operational costs and reliability in power conversion applications.

Applications of PWM Inverters

PWM inverters are essential in applications requiring precise motor control such as variable speed drives in industrial automation and electric vehicles, where efficiency and torque regulation are critical. These inverters optimize power conversion by modulating pulse widths to reduce harmonics and improve motor performance in HVAC systems and renewable energy setups like solar power inverters. Your choice of PWM inverter ensures enhanced energy savings and smoother operation in sensitive electronic devices and robotics.

Applications of VSI

Voltage Source Inverters (VSI) are widely used in renewable energy systems, such as photovoltaic solar power and wind energy conversion, due to their ability to efficiently convert DC to controlled AC power. VSI technology is essential in motor drives for industrial automation, providing precise speed and torque control in applications like robotics and electric vehicles. Their robust design also makes them suitable for uninterruptible power supplies (UPS) and grid-tied inverters, ensuring stable power delivery and high-quality output.

Advantages and Disadvantages of PWM Inverter

PWM inverters offer precise control of output voltage and frequency, resulting in higher efficiency and reduced harmonic distortion compared to VSI (Voltage Source Inverters). They excel in applications requiring smooth, clean power such as motor drives and renewable energy systems but tend to have higher cost and complexity due to advanced switching techniques. Limitations include increased electromagnetic interference (EMI) and the need for sophisticated control circuits, which can impact overall system design and maintenance.

Advantages and Disadvantages of VSI

Voltage Source Inverters (VSI) offer advantages such as high efficiency, simpler control methods, and the ability to handle inductive loads effectively, making them suitable for variable frequency drives and renewable energy systems. Their disadvantages include susceptibility to overvoltage due to inductive load switching, limited short-circuit current capability, and typically higher harmonic distortion compared to other inverter types. Despite these drawbacks, VSIs remain popular for applications requiring precise voltage control and smooth output waveforms.

Choosing the Right Inverter: Factors to Consider

When choosing the right inverter, factors such as switching frequency, waveform quality, and efficiency are crucial in differentiating PWM inverters from Voltage Source Inverters (VSI). PWM inverters offer precise voltage control and reduced harmonic distortion, making them suitable for sensitive applications, while VSIs provide a simpler design and cost-effectiveness for less demanding uses. Your selection should account for load type, power quality requirements, and system complexity to ensure optimal performance.

pwm inverter vs vsi Infographic

electrown.com

electrown.com