Hysteresis control offers rapid switching with robust disturbance rejection, making it ideal for applications requiring fast dynamic response, while PI control provides steady-state accuracy and smooth output by continuously adjusting control signals based on error integration. Discover how these control strategies compare and determine which suits Your system's needs by exploring the rest of the article.

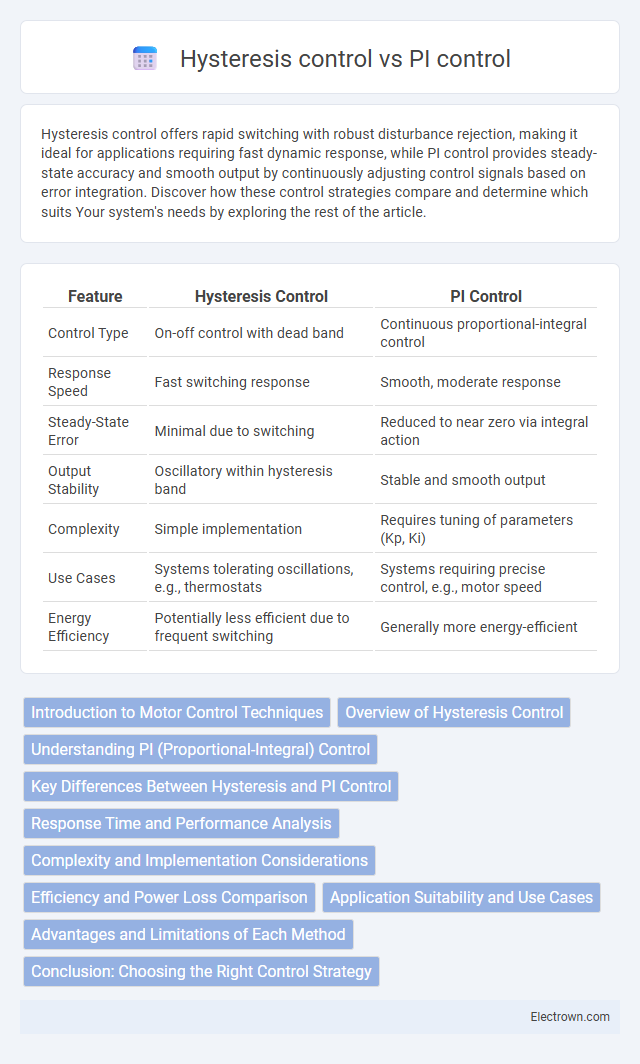

Table of Comparison

| Feature | Hysteresis Control | PI Control |

|---|---|---|

| Control Type | On-off control with dead band | Continuous proportional-integral control |

| Response Speed | Fast switching response | Smooth, moderate response |

| Steady-State Error | Minimal due to switching | Reduced to near zero via integral action |

| Output Stability | Oscillatory within hysteresis band | Stable and smooth output |

| Complexity | Simple implementation | Requires tuning of parameters (Kp, Ki) |

| Use Cases | Systems tolerating oscillations, e.g., thermostats | Systems requiring precise control, e.g., motor speed |

| Energy Efficiency | Potentially less efficient due to frequent switching | Generally more energy-efficient |

Introduction to Motor Control Techniques

Hysteresis control offers rapid and simple switching behavior ideal for precise motor current regulation, minimizing response time in dynamic applications. PI control provides steady-state error correction by continuously adjusting motor inputs, enhancing stability and smooth operation in varying load conditions. Your choice between these methods depends on the desired balance of speed, accuracy, and complexity in motor control systems.

Overview of Hysteresis Control

Hysteresis control is a widely used technique in power electronics for current regulation due to its simplicity and fast dynamic response. It operates by maintaining the controlled variable within a predefined hysteresis band, switching the output state whenever the variable crosses the band limits. This method offers reduced computational complexity compared to PI control, enabling efficient real-time performance in applications such as motor drives and inverters.

Understanding PI (Proportional-Integral) Control

PI (Proportional-Integral) control combines proportional action, which responds to the current error, with integral action that accumulates past errors to eliminate steady-state deviation. This control method is widely used in industrial automation for its ability to provide smooth, stable control and accurate setpoint tracking. Unlike hysteresis control, which switches states based on threshold bands, PI control adjusts output continuously, optimizing performance in processes requiring precision and minimal oscillation.

Key Differences Between Hysteresis and PI Control

Hysteresis control uses a switching mechanism based on predefined upper and lower tolerance bands, ensuring fast, non-linear response with inherent oscillation around the setpoint. PI (Proportional-Integral) control provides continuous output adjustment by minimizing the error over time through proportional and integral actions, resulting in smoother control with potential steady-state error elimination. Key differences include response speed, control output nature, and suitability for applications requiring either rapid switching or precise steady-state regulation.

Response Time and Performance Analysis

Hysteresis control offers faster response times due to its bang-bang operation, minimizing delay by switching outputs only when the error exceeds set thresholds. PI control provides smoother performance with continuous adjustment, but may experience slower response due to integral action and overshoot risks in dynamic systems. Performance analysis shows hysteresis is ideal for rapid switching applications, while PI excels in steady-state accuracy and reducing steady error.

Complexity and Implementation Considerations

Hysteresis control offers simpler implementation with fewer parameters to tune, making it suitable for systems requiring fast dynamic response and robustness to parameter variations. PI control demands precise tuning of proportional and integral gains, increasing complexity but providing smoother, steady-state performance in linear systems. Your choice depends on the trade-off between ease of implementation with quick response (hysteresis) and fine-tuned accuracy with steady control action (PI).

Efficiency and Power Loss Comparison

Hysteresis control offers higher responsiveness and lower switching frequency, resulting in reduced power loss and improved efficiency in dynamic load conditions compared to PI control. PI controllers tend to produce constant switching frequency, which can cause higher switching losses and decreased efficiency under varying operating points. Overall, hysteresis control achieves better power efficiency by minimizing switching events, while PI control provides smoother regulation but at the cost of increased power dissipation.

Application Suitability and Use Cases

Hysteresis control excels in applications requiring fast dynamic response and simplicity, such as power converters and motor drives where switching frequency varies with load conditions. PI control is preferred for systems demanding precise steady-state accuracy and smooth control, commonly found in temperature regulation, process control, and industrial automation. Selecting between them depends on the need for rapid switching performance with minimal overshoot (hysteresis) versus stable, fine-tuned control over output variables (PI).

Advantages and Limitations of Each Method

Hysteresis control offers fast dynamic response and robust performance under parameter variations but can cause variable switching frequency and increased power loss in power converters. PI control provides precise steady-state error elimination and simplicity in linear systems but may suffer from slower transient response and sensitivity to system parameter changes. Each method's suitability depends on application-specific requirements such as speed, accuracy, and system stability.

Conclusion: Choosing the Right Control Strategy

Hysteresis control offers fast dynamic response and simplicity but can lead to variable switching frequency and increased electromagnetic interference. PI control provides precise steady-state performance with fixed switching frequency, suitable for applications requiring stability and low noise. Your choice depends on the priority between rapid response and consistent output quality, with hysteresis ideal for quick transient handling and PI optimal for steady, predictable control.

Hysteresis control vs PI control Infographic

electrown.com

electrown.com