Back-to-back thyristors provide controlled bidirectional current flow by pairing two thyristors in opposite directions, enabling precise switching in AC circuits, while a TRIAC inherently allows current flow in both directions with simpler control but may suffer from less precise switching capabilities. Explore the rest of the article to understand which component best suits your specific application needs.

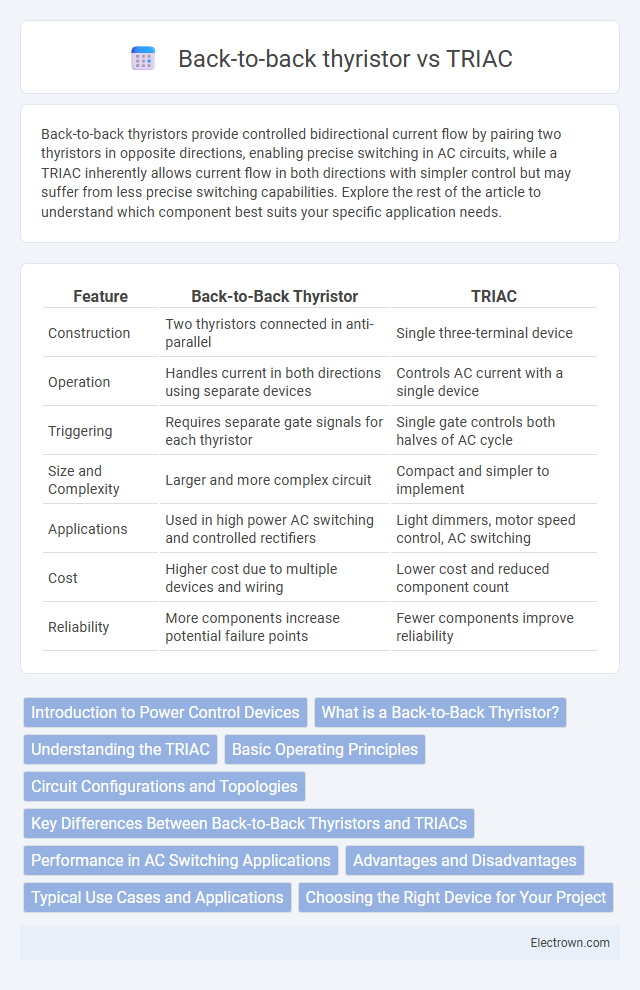

Table of Comparison

| Feature | Back-to-Back Thyristor | TRIAC |

|---|---|---|

| Construction | Two thyristors connected in anti-parallel | Single three-terminal device |

| Operation | Handles current in both directions using separate devices | Controls AC current with a single device |

| Triggering | Requires separate gate signals for each thyristor | Single gate controls both halves of AC cycle |

| Size and Complexity | Larger and more complex circuit | Compact and simpler to implement |

| Applications | Used in high power AC switching and controlled rectifiers | Light dimmers, motor speed control, AC switching |

| Cost | Higher cost due to multiple devices and wiring | Lower cost and reduced component count |

| Reliability | More components increase potential failure points | Fewer components improve reliability |

Introduction to Power Control Devices

Back-to-back thyristors consist of two thyristors connected in inverse parallel, enabling bidirectional power control ideal for AC applications with high power ratings. TRIACs, on the other hand, are single semiconductor devices capable of controlling current flow in both directions, commonly used in low to medium power AC switching. Choosing between these power control devices depends on your application's requirements for control precision, switching speed, and power handling capabilities.

What is a Back-to-Back Thyristor?

A Back-to-Back Thyristor consists of two thyristors connected in anti-parallel to control AC power by allowing current flow in both directions. Unlike a TRIAC, which is a single three-terminal device designed for bidirectional control, a Back-to-Back Thyristor setup offers greater flexibility in handling higher voltage and current ratings. Your choice between these devices depends on the specific requirements for control precision and load characteristics in AC power applications.

Understanding the TRIAC

The TRIAC is a semiconductor device capable of controlling AC power by allowing current flow in both directions, making it suitable for AC applications unlike back-to-back thyristors which require separate triggering for each quadrant. Its ability to switch on and off with a single gate signal simplifies circuit design, offering efficient phase control for dimmers and motor speed controllers. Understanding your TRIAC's bidirectional conduction and gate triggering characteristics ensures optimized performance in AC power regulation.

Basic Operating Principles

Back-to-back thyristors operate by connecting two thyristors in inverse parallel, allowing control of AC power by switching each half-cycle independently, while TRIACs function as a single device that can conduct current in both directions when triggered. Both devices manage AC loads, but thyristors require separate gate signals for each half-cycle, whereas a TRIAC needs only one gate control to trigger conduction throughout the AC waveform. Your choice between these components depends on the complexity and precision required in controlling AC power in applications like motor speed controllers or dimmer switches.

Circuit Configurations and Topologies

Back-to-back thyristor configurations involve connecting two thyristors in anti-parallel to handle AC power control, enabling precise phase angle modulation in high-power applications. TRIACs, being single devices with three terminals, simplify the circuit topology by allowing bidirectional current flow without the need for paired components, reducing complexity and cost. While back-to-back thyristor circuits offer flexibility in triggering and higher current ratings, TRIACs are preferred for compact, low to medium power applications due to their simpler wiring and integrated bidirectional conduction.

Key Differences Between Back-to-Back Thyristors and TRIACs

Back-to-back thyristors consist of two SCRs connected in anti-parallel to control AC power by allowing current flow in both directions, whereas TRIACs are single devices capable of bidirectional current conduction through a single semiconductor structure. Back-to-back thyristors provide independent gate control for each SCR, enabling precise triggering and higher control flexibility, while TRIACs have a single gate terminal, simplifying the triggering circuitry but limiting control granularity. The key difference lies in switching characteristics and applications: back-to-back thyristors handle higher voltages and currents with improved robustness, making them suitable for industrial motor controls, whereas TRIACs are preferred for low-power AC applications like light dimmers and household appliances.

Performance in AC Switching Applications

Back-to-back thyristors offer superior control and reliability in AC switching applications by allowing precise phase angle control and higher voltage ratings compared to TRIACs. TRIACs provide simpler and more compact designs suitable for low to medium power loads but can experience issues with dv/dt sensitivity and false triggering. Your choice between these components depends on the application's power requirements and the need for accurate switching performance.

Advantages and Disadvantages

Back-to-back thyristors offer precise control and higher voltage handling capabilities compared to TRIACs, making them suitable for high-power applications and providing improved efficiency in AC power control. However, they require complex gate drive circuits and generate more electromagnetic interference (EMI), increasing system complexity and implementation cost. TRIACs are simpler to use and cost-effective for low to medium power devices, but they suffer from slower switching speeds and limited control in inductive loads, resulting in less precise phase control.

Typical Use Cases and Applications

Back-to-back thyristors are commonly used in high-power applications requiring precise control of AC power, such as motor speed control, phase angle control in industrial heating, and solid-state relays. TRIACs are typically employed in low to medium power applications including light dimmers, small motor controls, and household appliance switching due to their ability to control AC in both halves of the cycle with a single device. Both devices enable effective AC load control but differ significantly in their power handling capabilities and switching precision, influencing their application scope in industrial versus domestic environments.

Choosing the Right Device for Your Project

Back-to-back thyristors offer precise control and higher voltage handling, making them ideal for applications requiring unidirectional current flow and robust performance in industrial settings. TRIACs provide simplified AC switching with bidirectional current control, suitable for low to medium power applications such as light dimmers and motor speed controllers. Selecting the right device depends on load characteristics, switching frequency, and voltage requirements to optimize efficiency and reliability in your specific project.

Back-to-back thyristor vs TRIAC Infographic

electrown.com

electrown.com