Avalanche-rated MOSFETs are designed to safely handle energy spikes during avalanche conditions without damage, offering enhanced robustness for high-voltage and transient-heavy applications, while non-avalanche-rated MOSFETs lack this protection and may fail under such stress. To understand how these differences impact your circuit design and performance, continue reading the rest of the article.

Table of Comparison

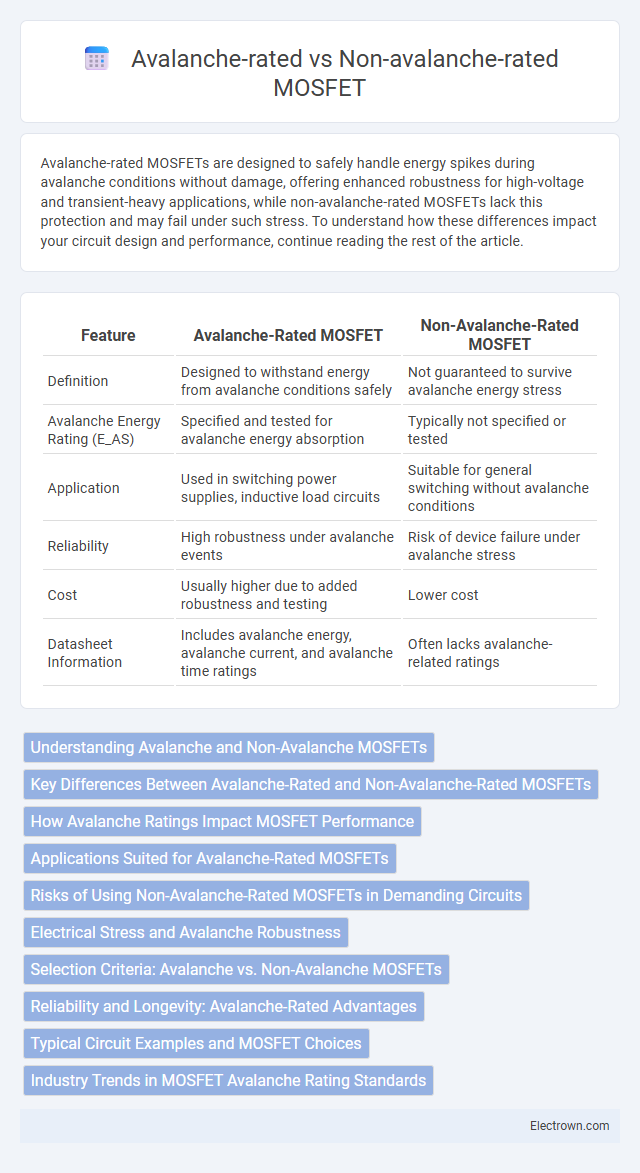

| Feature | Avalanche-Rated MOSFET | Non-Avalanche-Rated MOSFET |

|---|---|---|

| Definition | Designed to withstand energy from avalanche conditions safely | Not guaranteed to survive avalanche energy stress |

| Avalanche Energy Rating (E_AS) | Specified and tested for avalanche energy absorption | Typically not specified or tested |

| Application | Used in switching power supplies, inductive load circuits | Suitable for general switching without avalanche conditions |

| Reliability | High robustness under avalanche events | Risk of device failure under avalanche stress |

| Cost | Usually higher due to added robustness and testing | Lower cost |

| Datasheet Information | Includes avalanche energy, avalanche current, and avalanche time ratings | Often lacks avalanche-related ratings |

Understanding Avalanche and Non-Avalanche MOSFETs

Avalanche-rated MOSFETs are designed to handle and survive high-voltage spikes caused by inductive load switching or transient events, ensuring reliability under avalanche energy conditions (E_AS). Non-avalanche-rated MOSFETs lack this capability and may suffer permanent damage when exposed to avalanche breakdown, limiting their use in circuits with high transient voltage stresses. Understanding these differences is critical for selecting MOSFETs in power electronics applications where energy dissipation during switching is a key factor.

Key Differences Between Avalanche-Rated and Non-Avalanche-Rated MOSFETs

Avalanche-rated MOSFETs are designed to withstand high energy pulses caused by voltage spikes during switching, featuring robust avalanche energy (E_AS) ratings and enhanced ruggedness to prevent device failure. Non-avalanche-rated MOSFETs lack this protective capability, making them susceptible to damage under inductive load conditions or unexpected voltage transients. Key differences include avalanche energy capability, ruggedness under transient conditions, and suitability for high-voltage switching applications where energy dissipation is critical.

How Avalanche Ratings Impact MOSFET Performance

Avalanche ratings define a MOSFET's ability to withstand high voltage spikes during switching events or load dumps, directly impacting device robustness and reliability in harsh electrical environments. Avalanche-rated MOSFETs feature enhanced ruggedness, ensuring sustained operation under transient overvoltage conditions without failure, crucial for applications in automotive, industrial, and power management systems. Non-avalanche-rated MOSFETs, lacking this durability, face increased risk of damage and reduced lifespan when exposed to inductive load switching or voltage surges.

Applications Suited for Avalanche-Rated MOSFETs

Avalanche-rated MOSFETs are specifically designed to withstand the energy generated during inductive load switching and voltage spikes, making them ideal for applications such as motor drives, power supplies, and automotive electronics. These devices ensure reliability and durability in circuits that frequently experience transient voltage conditions, protecting your equipment from potential damage. Non-avalanche-rated MOSFETs are better suited for low-voltage, low-energy switching tasks where such transient conditions are minimal or controlled.

Risks of Using Non-Avalanche-Rated MOSFETs in Demanding Circuits

Using non-avalanche-rated MOSFETs in demanding circuits poses significant risks such as device failure due to inability to handle high voltage spikes caused by inductive loads or switching transients. Avalanche-rated MOSFETs are designed to absorb and safely dissipate the avalanche energy generated during voltage surges, preventing breakdown and improving reliability. Failure to use avalanche-rated components can lead to catastrophic circuit damage, increased maintenance costs, and reduced overall system lifespan.

Electrical Stress and Avalanche Robustness

Avalanche-rated MOSFETs are designed to withstand high electrical stress and avalanche conditions by incorporating robust avalanche energy ratings (E_AS) and optimized ruggedness parameters to prevent device failure during voltage spikes. Non-avalanche-rated MOSFETs lack this enhanced protection, making them more susceptible to damage under avalanche events, potentially compromising your system's reliability. Choosing avalanche-rated MOSFETs ensures improved avalanche robustness and longevity in applications with transient voltage stresses.

Selection Criteria: Avalanche vs. Non-Avalanche MOSFETs

Selecting between avalanche-rated and non-avalanche MOSFETs depends on the application's voltage stress and energy absorption requirements during inductive load switching or transient conditions. Avalanche-rated MOSFETs feature rugged construction and energy-handling capacity designed to withstand avalanche energy without failure, making them suitable for circuits with frequent or high-voltage transients. Non-avalanche MOSFETs lack this robustness and are optimal for steady-state or low-stress environments where avalanche events are unlikely or controlled.

Reliability and Longevity: Avalanche-Rated Advantages

Avalanche-rated MOSFETs are designed to withstand the high-energy voltage spikes caused by inductive load switching, significantly enhancing reliability and device longevity compared to non-avalanche-rated MOSFETs. These components feature rugged construction and optimized semiconductor design that prevent catastrophic failure during avalanche events, ensuring stable operation under harsh conditions. Choosing an avalanche-rated MOSFET for your application helps you achieve improved durability and reduced maintenance in demanding electrical environments.

Typical Circuit Examples and MOSFET Choices

Avalanche-rated MOSFETs are preferred in circuits with frequent voltage spikes and inductive loads, such as switching regulators, motor drivers, and power inverters, due to their ability to withstand and absorb avalanche energy without damage. Non-avalanche-rated MOSFETs are typically chosen for low-stress applications like linear regulators and DC-DC converters where voltage transients are minimal and cost efficiency is prioritized. Selecting an avalanche-rated MOSFET involves analyzing the maximum avalanche energy (E_AS) and repetitive avalanche current specifications to ensure reliable operation under transient conditions.

Industry Trends in MOSFET Avalanche Rating Standards

Industry trends in MOSFET avalanche rating standards emphasize improved reliability and efficiency for power electronics in automotive, renewable energy, and industrial applications. Manufacturers increasingly adopt stricter avalanche energy (E_AS) and avalanche current (I_AS) criteria to enhance device robustness under inductive load switching and transient conditions. Innovations concentrate on advanced silicon carbide (SiC) and gallium nitride (GaN) MOSFETs with higher avalanche ratings to support growing demands in electric vehicles, grid infrastructure, and high-frequency power conversion.

Avalanche-rated vs Non-avalanche-rated MOSFET Infographic

electrown.com

electrown.com