Dual-diffused MOS (DMOS) transistors offer higher current handling and faster switching speeds compared to single-diffused MOS (SMOS) devices due to their specialized doping profiles and structure. Explore the detailed differences and benefits to determine which MOS technology best suits your circuit design needs.

Table of Comparison

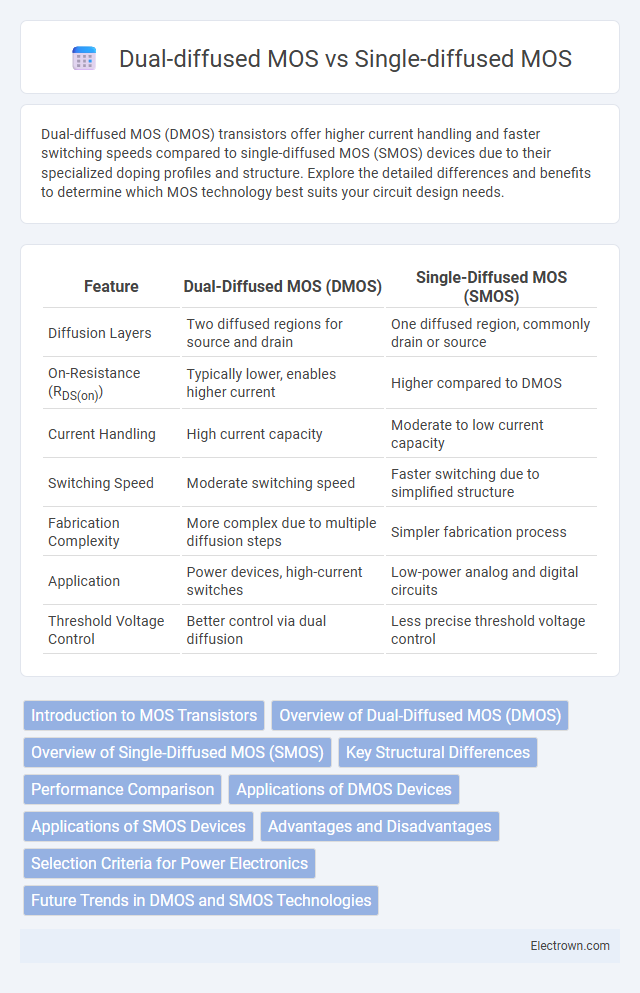

| Feature | Dual-Diffused MOS (DMOS) | Single-Diffused MOS (SMOS) |

|---|---|---|

| Diffusion Layers | Two diffused regions for source and drain | One diffused region, commonly drain or source |

| On-Resistance (RDS(on)) | Typically lower, enables higher current | Higher compared to DMOS |

| Current Handling | High current capacity | Moderate to low current capacity |

| Switching Speed | Moderate switching speed | Faster switching due to simplified structure |

| Fabrication Complexity | More complex due to multiple diffusion steps | Simpler fabrication process |

| Application | Power devices, high-current switches | Low-power analog and digital circuits |

| Threshold Voltage Control | Better control via dual diffusion | Less precise threshold voltage control |

Introduction to MOS Transistors

MOS transistors consist of Metal-Oxide-Semiconductor structures essential for switching and amplification in integrated circuits, with Single-diffused MOS (SDMOS) transistors featuring a single diffusion region that simplifies fabrication but may limit performance. Dual-diffused MOS (DMOS) transistors incorporate two diffusion steps--usually a lightly doped drain and a heavily doped source--to enhance current handling and reduce on-resistance, making them ideal for high-power applications. The structural differences between SDMOS and DMOS significantly impact their electrical characteristics, such as breakdown voltage and switching speed, influencing their suitability for specific electronic designs.

Overview of Dual-Diffused MOS (DMOS)

Dual-Diffused MOS (DMOS) transistors feature a specialized doping process with dual diffusion steps to create a drift region that enhances voltage handling and reduces on-resistance compared to Single-Diffused MOS devices. The DMOS structure enables higher current capacity and better thermal performance, making it ideal for power applications such as motor drives and power supplies. Understanding the benefits of DMOS technology can help you optimize your circuit designs for efficiency and reliability in high-power environments.

Overview of Single-Diffused MOS (SMOS)

Single-Diffused MOS (SMOS) transistors feature a single diffusion region that forms either the source or the drain, resulting in a simpler fabrication process and reduced parasitic capacitances compared to more complex structures. SMOS devices typically exhibit lower threshold voltages and faster switching speeds, making them suitable for high-frequency applications and low-power circuits. The single diffusion profile allows improved control over channel formation, enhancing device reliability and performance in analog and digital integrated circuits.

Key Structural Differences

Dual-diffused MOS (DMOS) transistors feature two diffusion steps creating a graded channel region, allowing for enhanced voltage handling and lower on-resistance compared to Single-diffused MOS (SMOS) devices with a single diffusion. The DMOS structure employs both N+ source and P-body regions, enabling improved control over the channel and reduced short-channel effects. In contrast, SMOS devices have a simpler architecture with only one diffusion, typically resulting in higher resistance and less efficient current flow under high voltage conditions.

Performance Comparison

Dual-diffused MOS (DMOS) transistors typically offer higher breakdown voltages and better current handling capabilities than single-diffused MOS devices, making them ideal for power applications. You benefit from improved on-resistance and faster switching speeds in DMOS due to their optimized channel doping profile, which reduces conduction losses. Single-diffused MOS devices, while simpler and cheaper to manufacture, generally exhibit lower performance in high-voltage and high-current scenarios.

Applications of DMOS Devices

DMOS devices excel in high-power applications such as motor drives, power supplies, and audio amplifiers due to their low on-resistance and fast switching capabilities. Single-diffused MOSFETs are often preferred for lower power, high-frequency switching tasks because of their simpler structure and smaller size. Your choice of DMOS technology significantly enhances performance in industrial power management and automotive electronics by providing improved efficiency and thermal handling.

Applications of SMOS Devices

Single-diffused MOS (SMOS) devices are widely utilized in low-power, high-speed digital circuits and analog applications due to their simpler fabrication process and reduced parasitic capacitances. These characteristics make SMOS ideal for integrated circuits in consumer electronics and automotive sensors, where efficiency and reliability are paramount. Your choice of SMOS devices can enhance circuit performance in applications requiring precise control over threshold voltages and device dimensions.

Advantages and Disadvantages

Dual-diffused MOS (DMOS) transistors offer advantages such as higher current handling capability and lower on-resistance compared to Single-diffused MOS (SMOS), making them suitable for high-power applications. However, DMOS devices typically exhibit increased fabrication complexity and larger chip area, which may lead to higher costs. Your choice between DMOS and SMOS depends on balancing performance needs with manufacturing constraints and budget.

Selection Criteria for Power Electronics

Dual-diffused MOSFETs (DMOS) offer higher current handling and faster switching speeds, making them ideal for power electronics requiring efficient thermal management and robust performance under high voltage. Single-diffused MOSFETs generally feature lower manufacturing complexity and cost but deliver reduced current capacity and slower switching, limiting their use to low-power applications. Selection criteria should prioritize DMOS for high-power converters and motor drives, while single-diffused MOSFETs fit well in low-power, cost-sensitive circuits.

Future Trends in DMOS and SMOS Technologies

Emerging trends in DMOS technology emphasize enhanced power efficiency and miniaturization through advanced silicon carbide (SiC) substrates, enabling higher voltage handling and faster switching speeds compared to traditional silicon-based SMOS devices. Integration of wide bandgap materials into DMOS structures is driving significant improvements in thermal management and durability, crucial for electric vehicle and renewable energy applications. SMOS technologies are evolving with novel doping techniques and ultra-thin gate oxides to boost low-voltage performance and reduce leakage currents, targeting next-generation low-power integrated circuits.

Dual-diffused MOS vs Single-diffused MOS Infographic

electrown.com

electrown.com