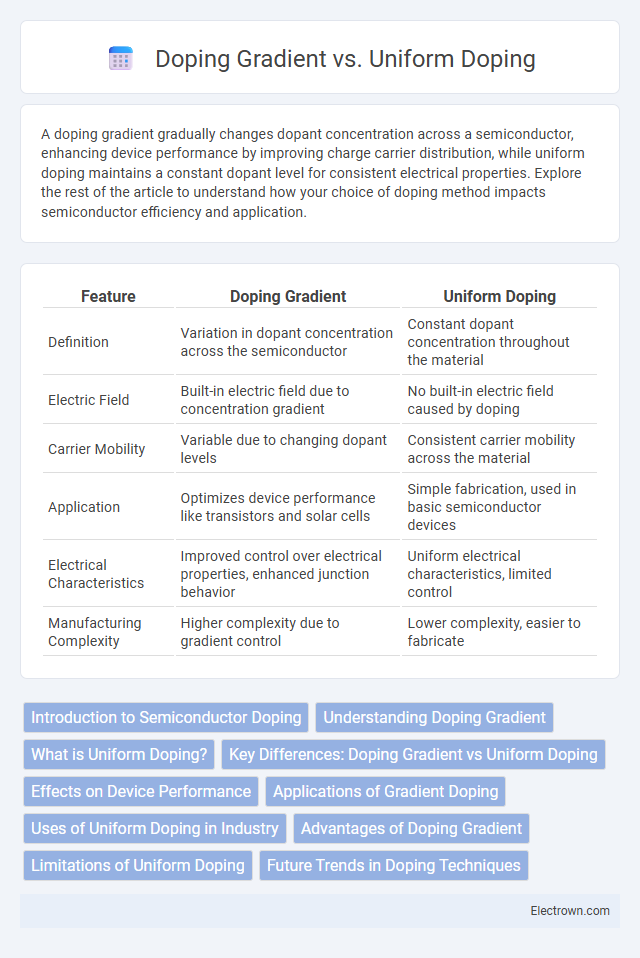

A doping gradient gradually changes dopant concentration across a semiconductor, enhancing device performance by improving charge carrier distribution, while uniform doping maintains a constant dopant level for consistent electrical properties. Explore the rest of the article to understand how your choice of doping method impacts semiconductor efficiency and application.

Table of Comparison

| Feature | Doping Gradient | Uniform Doping |

|---|---|---|

| Definition | Variation in dopant concentration across the semiconductor | Constant dopant concentration throughout the material |

| Electric Field | Built-in electric field due to concentration gradient | No built-in electric field caused by doping |

| Carrier Mobility | Variable due to changing dopant levels | Consistent carrier mobility across the material |

| Application | Optimizes device performance like transistors and solar cells | Simple fabrication, used in basic semiconductor devices |

| Electrical Characteristics | Improved control over electrical properties, enhanced junction behavior | Uniform electrical characteristics, limited control |

| Manufacturing Complexity | Higher complexity due to gradient control | Lower complexity, easier to fabricate |

Introduction to Semiconductor Doping

Semiconductor doping introduces impurities into materials to modify their electrical properties, with doping gradients gradually varying dopant concentration across a region, unlike uniform doping where dopant concentration remains constant. Doping gradients enhance device performance by enabling better control over electric fields and charge distribution, crucial for advanced transistors and diodes. Your choice between gradient and uniform doping depends on the specific application, aiming to optimize conductivity, threshold voltage, and overall semiconductor behavior.

Understanding Doping Gradient

Doping gradient refers to the variation of dopant concentration across a semiconductor material, creating a non-uniform distribution that enhances device performance by improving carrier mobility and reducing junction capacitance. Uniform doping maintains a consistent dopant concentration throughout the semiconductor, providing predictable electrical characteristics but limiting optimization potential. Understanding doping gradient enables you to tailor semiconductor properties for high-efficiency devices, such as transistors and photodetectors, by precisely controlling electrical behavior at microscopic levels.

What is Uniform Doping?

Uniform doping refers to the consistent distribution of dopant atoms throughout a semiconductor material, ensuring an even electrical conductivity across the entire region. This technique simplifies device fabrication and provides predictable electrical characteristics, which are crucial for standard electronic components. Your semiconductor's performance stability often benefits from uniform doping by minimizing variations in carrier concentration.

Key Differences: Doping Gradient vs Uniform Doping

Doping gradient involves varying the concentration of dopants across a semiconductor material, creating a spatial change in electrical properties, while uniform doping maintains a consistent dopant concentration throughout the material. This gradient enables improved control over carrier distribution and electric field profiles, enhancing device performance in applications like transistors and power devices. Your choice between doping gradient and uniform doping impacts the semiconductor's behavior, affecting factors like junction depth, carrier mobility, and threshold voltage.

Effects on Device Performance

Doping gradients in semiconductor devices create electric fields that enhance carrier injection and reduce recombination, improving device efficiency and speed compared to uniform doping. Devices with graded doping profiles exhibit lower capacitance and enhanced breakdown voltage, enabling better high-frequency performance and reliability. Uniform doping offers simpler fabrication but often results in higher resistive losses and reduced control over carrier distribution, limiting overall device optimization.

Applications of Gradient Doping

Gradient doping enhances semiconductor device performance by creating a controlled variation in charge carrier concentration, improving efficiency in high-speed transistors and photodetectors. This technique is widely applied in solar cells to optimize charge separation and collection, boosting overall energy conversion efficiency. Your electronic devices benefit from gradient doping through enhanced speed, reduced power consumption, and improved sensitivity in optoelectronic applications.

Uses of Uniform Doping in Industry

Uniform doping is widely used in the semiconductor industry for manufacturing devices like resistors, diodes, and transistors where consistent electrical characteristics are crucial. This doping method ensures stable carrier concentration throughout the material, leading to predictable performance and enhanced reliability in integrated circuits. Your production processes benefit from uniform doping by achieving precise control over conductivity and minimizing variations during device fabrication.

Advantages of Doping Gradient

Doping gradient in semiconductors enhances carrier mobility by creating an electric field that drives charge carriers more efficiently compared to uniform doping. It reduces charge recombination and improves transistor switching speed, leading to better device performance and energy efficiency. Gradient doping also enables precise control over electrical properties, ideal for advanced semiconductor applications such as high-speed integrated circuits and power devices.

Limitations of Uniform Doping

Uniform doping creates a constant concentration of dopants throughout the semiconductor, which limits your ability to enhance device performance by controlling electric fields and charge carrier distribution. This lack of variation increases the likelihood of short-channel effects and degrades device scalability in advanced transistors. Doping gradients enable tailored junction depths and improved carrier mobility, overcoming the limitations present in uniform doping profiles.

Future Trends in Doping Techniques

Future trends in doping techniques highlight the shift from uniform doping to advanced doping gradient methods, enabling precise control of charge carrier distribution in semiconductor devices. Gradient doping enhances device performance, allowing improved electron mobility, reduced leakage currents, and optimized junction depths critical for next-generation transistors. Emerging techniques such as atomic layer doping and plasma doping are anticipated to drive innovations in nanoscale semiconductor fabrication, facilitating ultra-scaled, energy-efficient integrated circuits.

Doping gradient vs Uniform doping Infographic

electrown.com

electrown.com