Power factor correction ICs optimize energy efficiency by reducing reactive power and improving voltage stability, whereas regular rectifier ICs primarily convert AC to DC without addressing power quality issues. Discover how choosing the right IC can enhance your circuit's performance in the rest of this article.

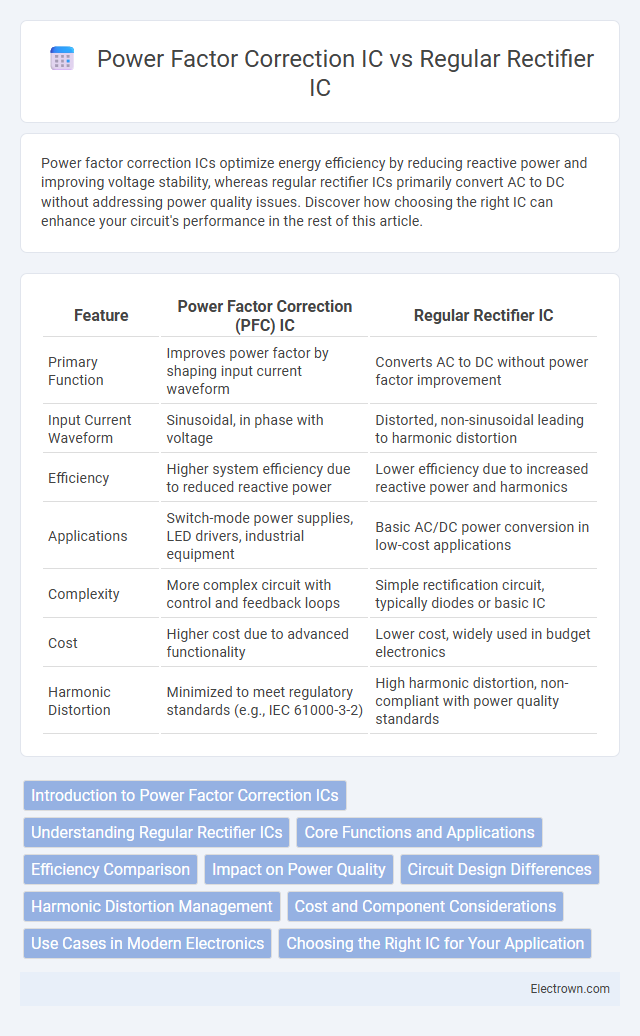

Table of Comparison

| Feature | Power Factor Correction (PFC) IC | Regular Rectifier IC |

|---|---|---|

| Primary Function | Improves power factor by shaping input current waveform | Converts AC to DC without power factor improvement |

| Input Current Waveform | Sinusoidal, in phase with voltage | Distorted, non-sinusoidal leading to harmonic distortion |

| Efficiency | Higher system efficiency due to reduced reactive power | Lower efficiency due to increased reactive power and harmonics |

| Applications | Switch-mode power supplies, LED drivers, industrial equipment | Basic AC/DC power conversion in low-cost applications |

| Complexity | More complex circuit with control and feedback loops | Simple rectification circuit, typically diodes or basic IC |

| Cost | Higher cost due to advanced functionality | Lower cost, widely used in budget electronics |

| Harmonic Distortion | Minimized to meet regulatory standards (e.g., IEC 61000-3-2) | High harmonic distortion, non-compliant with power quality standards |

Introduction to Power Factor Correction ICs

Power factor correction (PFC) ICs are designed to improve the power factor of electrical systems by minimizing reactive power and harmonics, resulting in enhanced energy efficiency and reduced electrical losses. Unlike regular rectifier ICs that merely convert AC to DC, PFC ICs actively regulate and shape the input current to closely match the input voltage waveform. This regulation reduces distortion in power lines, complies with international standards, and supports stable operation in high-performance power supplies.

Understanding Regular Rectifier ICs

Regular rectifier ICs convert alternating current (AC) to direct current (DC) by allowing current flow in one direction, but they do not improve power factor or reduce harmonic distortion. These ICs are typically used in simple power supplies where efficiency and regulatory compliance are less critical. Your application may require a Power Factor Correction (PFC) IC if minimizing energy losses and meeting stringent power quality standards are important.

Core Functions and Applications

Power factor correction (PFC) ICs actively regulate the input current to improve power factor and reduce harmonic distortion, enhancing energy efficiency in AC-DC power supplies. In contrast, regular rectifier ICs primarily convert AC to DC without addressing power factor, making them suitable for basic power conversion tasks in low-complexity applications. PFC ICs are essential in high-power and energy-sensitive systems such as LED drivers, server power supplies, and industrial equipment, while rectifier ICs are typically used in simple adapters and low-power electronics.

Efficiency Comparison

Power factor correction (PFC) ICs significantly enhance efficiency by minimizing reactive power and harmonics, leading to improved energy usage and reduced losses compared to regular rectifier ICs. Regular rectifier ICs primarily convert AC to DC without addressing power quality, resulting in lower overall system efficiency and increased electrical interference. Your choice of a PFC IC can optimize power delivery and reduce electricity costs by ensuring a cleaner, more efficient current flow in electronic devices.

Impact on Power Quality

Power factor correction (PFC) ICs significantly enhance power quality by reducing harmonic distortion and improving the power factor, leading to more efficient energy use and lower reactive power. Regular rectifier ICs, while converting AC to DC, typically lack mechanisms to correct power factor, resulting in higher total harmonic distortion (THD) and reduced overall power quality. Implementing PFC ICs helps comply with international standards such as IEC 61000-3-2, ensuring cleaner energy consumption and minimizing electrical noise in the system.

Circuit Design Differences

Power factor correction (PFC) ICs incorporate advanced circuitry to actively manage input current waveform, typically including boost converters and error amplifiers to minimize harmonic distortion and improve efficiency. Regular rectifier ICs primarily focus on converting AC to DC with simpler bridge diode configurations and lack components for real-time current correction. The distinct circuit design of PFC ICs enables compliance with energy standards by shaping the input current closer to a sinusoidal waveform, whereas traditional rectifier ICs do not actively control power factor.

Harmonic Distortion Management

Power factor correction (PFC) ICs actively manage harmonic distortion by shaping input current to align closely with voltage waveforms, significantly reducing total harmonic distortion (THD) compared to regular rectifier ICs. Regular rectifier ICs typically allow nonlinear currents, resulting in high harmonic content that can impair power quality and violate regulatory standards. Implementing PFC ICs ensures compliance with IEC 61000-3-2 standards and enhances energy efficiency by minimizing harmonic disturbances in AC power systems.

Cost and Component Considerations

Power factor correction (PFC) ICs typically incur higher costs than regular rectifier ICs due to their complex design and additional components needed for active power factor management. Your overall system cost may increase as PFC solutions require inductors, capacitors, and more sophisticated control circuitry, whereas regular rectifier ICs utilize simpler diodes, reducing component count and manufacturing expenses. Choosing between these ICs depends on balancing the expense of improved energy efficiency against initial hardware investment.

Use Cases in Modern Electronics

Power factor correction (PFC) ICs are essential in modern electronics where energy efficiency and compliance with regulatory standards are critical, such as in LED drivers, industrial power supplies, and renewable energy systems. Regular rectifier ICs primarily handle AC to DC conversion but lack the ability to improve power factor, making them suitable for simpler applications with fewer energy efficiency requirements. Your selection between PFC ICs and regular rectifier ICs depends on the need to minimize harmonic distortion and optimize power consumption in highly regulated or energy-conscious environments.

Choosing the Right IC for Your Application

Selecting the appropriate IC depends on your application's power quality and efficiency requirements; power factor correction (PFC) ICs optimize energy usage by minimizing reactive power and harmonics, whereas regular rectifier ICs primarily handle AC to DC conversion without improving power factor. PFC ICs are essential in industrial and high-power applications where compliance with regulatory standards and energy savings are critical, while regular rectifier ICs suffice for simpler, low-power devices. Analyzing load characteristics, input voltage, current ratings, and system complexity ensures optimal performance and cost-effectiveness in your electronic design.

Power factor correction IC vs regular rectifier IC Infographic

electrown.com

electrown.com