SiC MOSFETs offer lower on-resistance, higher thermal conductivity, and faster switching speeds compared to traditional Si MOSFETs, making them ideal for high-efficiency and high-power applications. Explore the advantages and trade-offs of SiC MOSFETs versus Si MOSFETs to determine which technology best suits your specific needs.

Table of Comparison

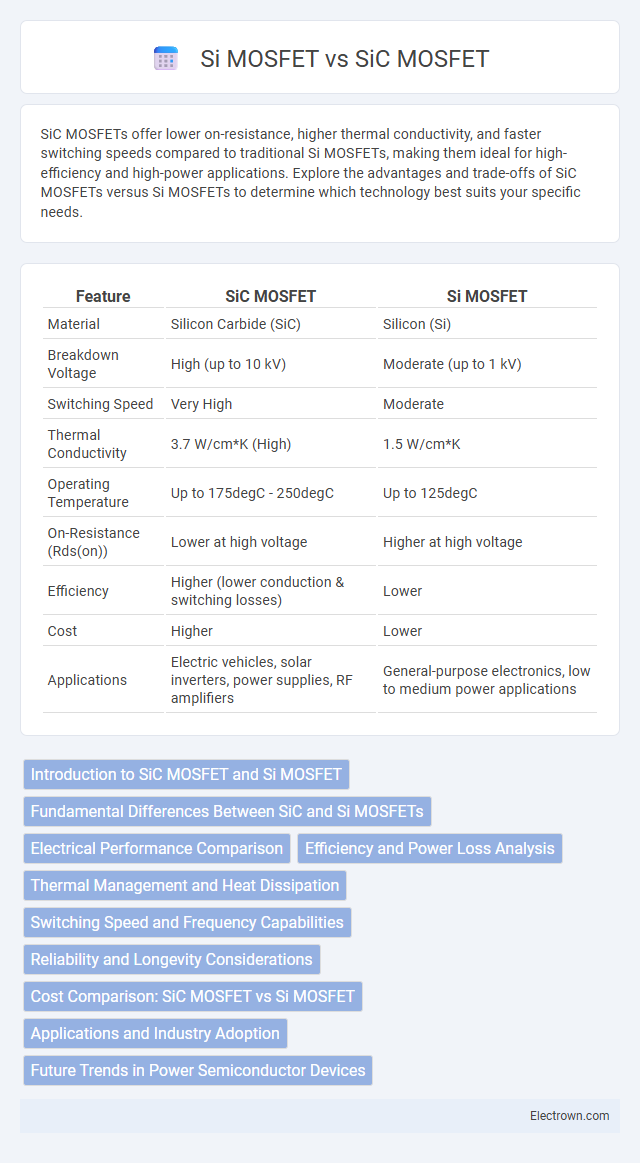

| Feature | SiC MOSFET | Si MOSFET |

|---|---|---|

| Material | Silicon Carbide (SiC) | Silicon (Si) |

| Breakdown Voltage | High (up to 10 kV) | Moderate (up to 1 kV) |

| Switching Speed | Very High | Moderate |

| Thermal Conductivity | 3.7 W/cm*K (High) | 1.5 W/cm*K |

| Operating Temperature | Up to 175degC - 250degC | Up to 125degC |

| On-Resistance (Rds(on)) | Lower at high voltage | Higher at high voltage |

| Efficiency | Higher (lower conduction & switching losses) | Lower |

| Cost | Higher | Lower |

| Applications | Electric vehicles, solar inverters, power supplies, RF amplifiers | General-purpose electronics, low to medium power applications |

Introduction to SiC MOSFET and Si MOSFET

SiC MOSFETs (Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistors) offer superior performance in high voltage and high temperature applications compared to traditional Si MOSFETs (Silicon Metal-Oxide-Semiconductor Field-Effect Transistors). SiC MOSFETs exhibit lower on-resistance, faster switching speeds, and higher thermal conductivity, making them ideal for power electronics in electric vehicles, renewable energy systems, and industrial motor drives. While Si MOSFETs remain widely used due to lower cost and mature manufacturing processes, SiC MOSFETs provide enhanced efficiency and reliability for demanding environments.

Fundamental Differences Between SiC and Si MOSFETs

SiC MOSFETs utilize silicon carbide as the semiconductor material, offering higher breakdown voltage, thermal conductivity, and switching speed compared to traditional silicon MOSFETs. The wide bandgap of SiC enables operation at elevated temperatures and voltages, resulting in improved efficiency and reduced cooling requirements in power electronics. Silicon MOSFETs, based on silicon, exhibit lower cost and mature manufacturing processes but struggle with higher conduction losses and slower switching speeds under high-power conditions.

Electrical Performance Comparison

SiC MOSFETs offer superior electrical performance compared to Si MOSFETs, including higher breakdown voltage and lower on-resistance, which results in increased efficiency and reduced power loss. Their faster switching speeds minimize switching losses and improve thermal management, making them ideal for high-frequency and high-power applications. When selecting components for your design, choosing SiC MOSFETs can enhance overall system performance and reliability.

Efficiency and Power Loss Analysis

SiC MOSFETs offer significantly higher efficiency compared to Si MOSFETs due to their lower on-resistance and faster switching speeds, which reduce conduction and switching losses. Power loss analysis reveals that SiC devices minimize heat generation, enhancing thermal management and enabling higher power density designs. Your power electronics systems benefit from improved performance and reduced energy consumption when utilizing SiC MOSFETs over traditional silicon counterparts.

Thermal Management and Heat Dissipation

SiC MOSFETs exhibit superior thermal management and heat dissipation properties compared to Si MOSFETs due to their higher thermal conductivity and wider bandgap, allowing operation at elevated temperatures with reduced cooling requirements. Your power electronics systems benefit from SiC devices' ability to maintain efficiency under high thermal stress, minimizing the risk of thermal runaway and enhancing overall reliability. This results in smaller, lighter heat sinks and improved system performance in high-power and high-frequency applications.

Switching Speed and Frequency Capabilities

SiC MOSFETs offer significantly higher switching speeds and frequency capabilities compared to traditional Si MOSFETs due to their superior material properties such as wider bandgap and higher electron mobility. This allows SiC devices to operate efficiently at switching frequencies up to several hundred kilohertz or even megahertz, reducing switching losses and improving overall system performance. Your power electronics applications can benefit from faster switching speeds, leading to smaller passive components and enhanced energy efficiency.

Reliability and Longevity Considerations

SiC MOSFETs demonstrate superior reliability and longevity compared to Si MOSFETs due to their higher thermal conductivity and wider bandgap, which enable operation at elevated temperatures with reduced degradation. The robust material properties of silicon carbide minimize wear-out mechanisms like hot carrier injection and oxide breakdown, significantly extending device lifespan under high-stress conditions. This results in consistent performance over prolonged periods in demanding applications such as automotive and industrial power electronics.

Cost Comparison: SiC MOSFET vs Si MOSFET

SiC MOSFETs generally have a higher upfront cost compared to Si MOSFETs due to complex manufacturing processes and material costs. However, SiC MOSFETs offer superior efficiency and thermal performance, which can reduce overall system costs through energy savings and smaller cooling requirements. In high-power, high-frequency applications, the total cost of ownership often favors SiC MOSFETs despite their higher initial price.

Applications and Industry Adoption

SiC MOSFETs outperform Si MOSFETs in high-power and high-frequency applications, making them ideal for electric vehicles, renewable energy systems, and industrial motor drives. The wide bandgap properties of SiC enable higher efficiency and thermal stability, which accelerates industry adoption in sectors demanding robust performance and energy savings. Your choice of SiC MOSFETs can lead to improved system reliability and lower overall operational costs in advanced power electronics.

Future Trends in Power Semiconductor Devices

SiC MOSFETs demonstrate superior efficiency and thermal performance compared to Si MOSFETs, making them the preferred choice for next-generation power semiconductor devices in electric vehicles and renewable energy systems. The ongoing advancements in SiC manufacturing processes aim to reduce costs and enhance device reliability, accelerating their adoption across high-power, high-frequency applications. Si MOSFETs will continue to dominate low-voltage, cost-sensitive markets, while SiC technology drives innovation in power electronics toward higher voltage ratings and increased energy density.

SiC MOSFET vs Si MOSFET Infographic

electrown.com

electrown.com