SiC Schottky diodes offer higher efficiency, faster switching speeds, and better thermal performance compared to traditional Si Schottky diodes, making them ideal for high-power and high-temperature applications. Explore the rest of the article to understand how these advantages can benefit your electronic designs.

Table of Comparison

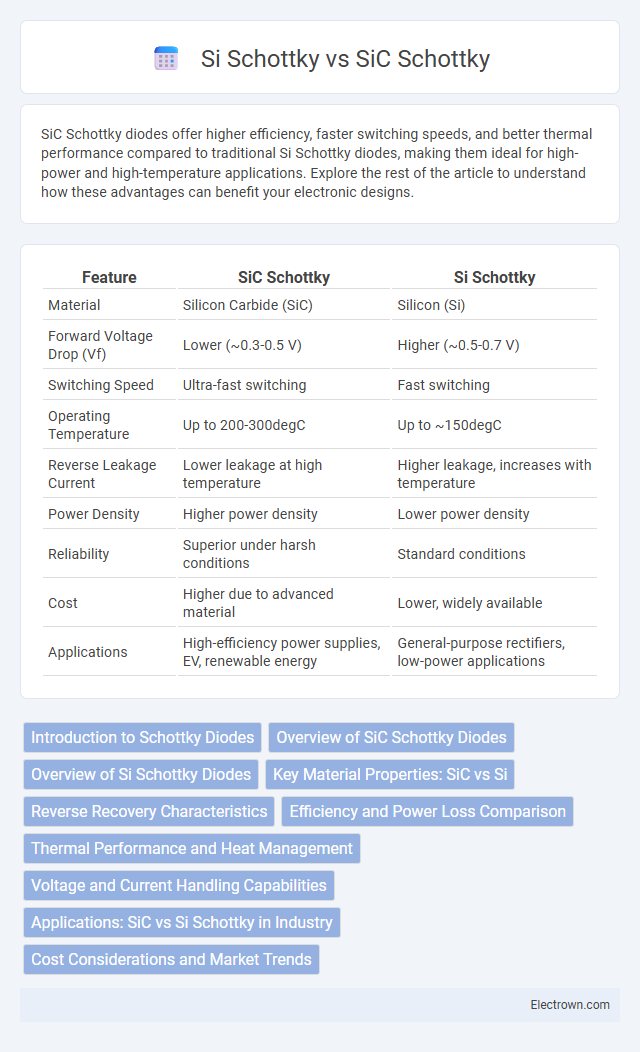

| Feature | SiC Schottky | Si Schottky |

|---|---|---|

| Material | Silicon Carbide (SiC) | Silicon (Si) |

| Forward Voltage Drop (Vf) | Lower (~0.3-0.5 V) | Higher (~0.5-0.7 V) |

| Switching Speed | Ultra-fast switching | Fast switching |

| Operating Temperature | Up to 200-300degC | Up to ~150degC |

| Reverse Leakage Current | Lower leakage at high temperature | Higher leakage, increases with temperature |

| Power Density | Higher power density | Lower power density |

| Reliability | Superior under harsh conditions | Standard conditions |

| Cost | Higher due to advanced material | Lower, widely available |

| Applications | High-efficiency power supplies, EV, renewable energy | General-purpose rectifiers, low-power applications |

Introduction to Schottky Diodes

SiC Schottky diodes use silicon carbide material, offering higher breakdown voltage, faster switching speed, and superior thermal conductivity compared to traditional Si Schottky diodes made from silicon. These differences enable SiC Schottky diodes to perform efficiently in high-power and high-temperature applications, reducing conduction and switching losses. The unique wide bandgap of SiC significantly improves diode robustness and reliability in advanced power electronics.

Overview of SiC Schottky Diodes

SiC Schottky diodes offer superior performance compared to traditional silicon (Si) Schottky diodes, featuring higher breakdown voltage, lower forward voltage drop, and enhanced thermal stability. These wide bandgap semiconductor devices enable faster switching speeds and reduced power losses, making them ideal for high-efficiency power conversion applications. The inherent robustness of silicon carbide materials allows SiC Schottky diodes to operate reliably in high-temperature and high-voltage environments, surpassing the limitations of silicon-based counterparts.

Overview of Si Schottky Diodes

Si Schottky diodes, made from silicon semiconductor material, offer fast switching speeds and low forward voltage drops, ideal for high-frequency applications. Compared to SiC Schottky diodes, Si Schottky diodes generally have lower thermal conductivity and voltage blocking capabilities, limiting their performance in high-power, high-temperature environments. Their ease of integration and cost-effectiveness make Si Schottky diodes widely used in low to medium power rectification and clamping circuits.

Key Material Properties: SiC vs Si

Silicon Carbide (SiC) Schottky diodes exhibit superior key material properties compared to Silicon (Si) Schottky diodes, including a wider bandgap of 3.26 eV versus 1.12 eV, which results in higher breakdown voltage and thermal stability. SiC's higher thermal conductivity (around 3.7 W/cm*K) enables efficient heat dissipation, making these devices ideal for high-power and high-temperature applications. Your choice of diode impacts device performance, with SiC Schottky diodes offering lower leakage current and faster switching speeds due to their intrinsic material advantages.

Reverse Recovery Characteristics

SiC Schottky diodes demonstrate significantly superior reverse recovery characteristics compared to Si Schottky diodes, displaying negligible reverse recovery charge (Qrr) and almost zero reverse recovery time. This results in lower switching losses and improved efficiency in high-frequency applications. Your power electronics designs benefit from enhanced thermal performance and reduced electromagnetic interference when utilizing SiC Schottky components.

Efficiency and Power Loss Comparison

SiC Schottky diodes exhibit significantly higher efficiency than Si Schottky diodes due to their lower forward voltage drop and minimal reverse recovery charge, which reduces conduction and switching losses. The wide bandgap of silicon carbide enables SiC Schottky diodes to operate at higher temperatures and voltages, decreasing power loss and improving thermal management in power electronics. Consequently, SiC Schottky devices are preferred in high-efficiency, high-power applications where reduced energy dissipation and enhanced reliability are critical.

Thermal Performance and Heat Management

SiC Schottky diodes exhibit significantly higher thermal conductivity (~120 W/m*K) compared to Si Schottky diodes (~150 W/m*K), enabling superior heat dissipation and improved thermal performance under high power conditions. The wide bandgap of SiC (3.26 eV) allows for operation at junction temperatures above 200degC, whereas Si devices are typically limited to around 150degC, reducing thermal stress and enhancing reliability in SiC-based systems. Enhanced thermal management in SiC Schottky devices minimizes cooling requirements and increases system efficiency in demanding power electronics applications.

Voltage and Current Handling Capabilities

SiC Schottky diodes offer significantly higher voltage handling capabilities, typically exceeding 600V and reaching up to 1700V, compared to Si Schottky diodes which usually operate below 200V. SiC devices also provide superior current density and thermal performance, enabling your applications to manage higher currents efficiently with reduced power losses. This makes SiC Schottky ideal for high-voltage, high-current environments where reliability and efficiency are critical.

Applications: SiC vs Si Schottky in Industry

SiC Schottky diodes excel in high-power and high-temperature industrial applications such as electric vehicle inverters, renewable energy systems, and power supplies due to their superior efficiency and lower switching losses compared to Si Schottky diodes. Si Schottky devices remain popular in low-voltage, cost-sensitive applications like consumer electronics and general-purpose rectification where thermal and power demands are less critical. Your choice between SiC and Si will depend on the specific industry's voltage, temperature, and efficiency requirements, with SiC offering advantages in harsh and high-performance environments.

Cost Considerations and Market Trends

SiC Schottky diodes, though initially more expensive due to complex manufacturing processes, are increasingly cost-competitive as production scales and technology matures, driven by growing demand in electric vehicles and high-efficiency power electronics. In contrast, Si Schottky devices offer lower upfront costs and established supply chains but face limitations in high-temperature and high-voltage applications, affecting long-term value. Market trends indicate a significant shift towards SiC Schottky adoption, propelled by its superior performance and decreasing cost gap, fostering widespread integration in industrial and automotive sectors.

SiC Schottky vs Si Schottky Infographic

electrown.com

electrown.com