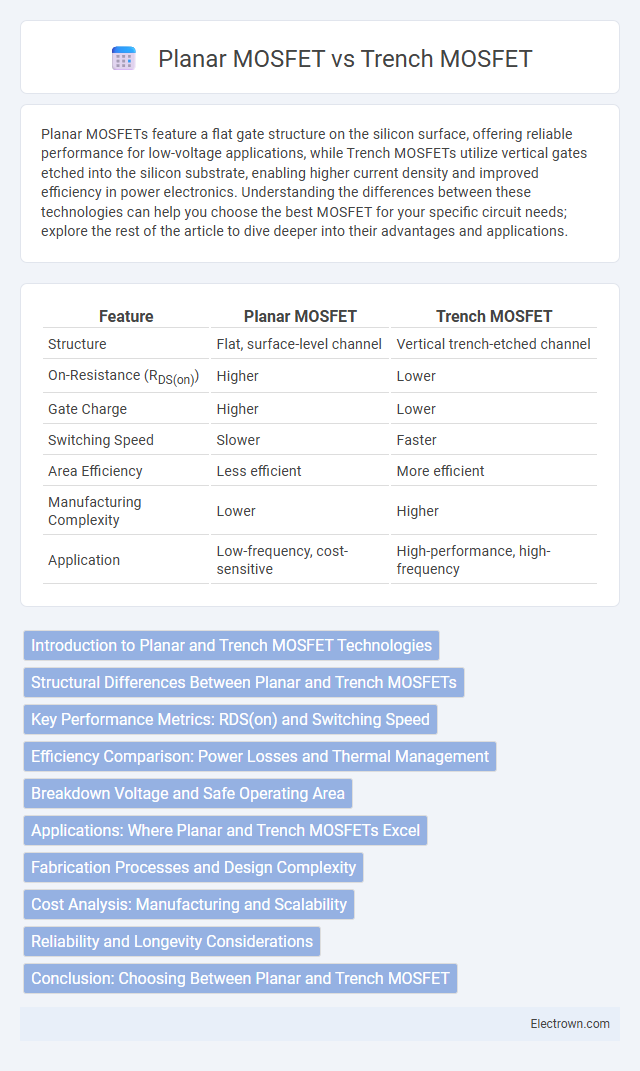

Planar MOSFETs feature a flat gate structure on the silicon surface, offering reliable performance for low-voltage applications, while Trench MOSFETs utilize vertical gates etched into the silicon substrate, enabling higher current density and improved efficiency in power electronics. Understanding the differences between these technologies can help you choose the best MOSFET for your specific circuit needs; explore the rest of the article to dive deeper into their advantages and applications.

Table of Comparison

| Feature | Planar MOSFET | Trench MOSFET |

|---|---|---|

| Structure | Flat, surface-level channel | Vertical trench-etched channel |

| On-Resistance (RDS(on)) | Higher | Lower |

| Gate Charge | Higher | Lower |

| Switching Speed | Slower | Faster |

| Area Efficiency | Less efficient | More efficient |

| Manufacturing Complexity | Lower | Higher |

| Application | Low-frequency, cost-sensitive | High-performance, high-frequency |

Introduction to Planar and Trench MOSFET Technologies

Planar MOSFET technology features a flat surface structure where the gate lies horizontally over the channel, making it simpler to manufacture but limiting scalability due to higher on-resistance and parasitic capacitances. Trench MOSFETs utilize vertical gate electrodes etched into the silicon substrate, enabling reduced on-resistance and improved current density by increasing channel width per unit area. This advancement in trench MOSFET design enhances switching performance and power efficiency, making it favorable for high-frequency and high-current applications.

Structural Differences Between Planar and Trench MOSFETs

Planar MOSFETs feature a horizontal gate structure atop the silicon surface, with current flowing laterally through the channel, whereas Trench MOSFETs utilize a vertical gate embedded into deep trenches that allows current to flow vertically, reducing on-resistance. The trench design enhances channel density by increasing the effective gate width per unit area, improving efficiency and switching performance in power applications. Understanding these structural differences helps You select the optimal MOSFET for low-loss power conversion and high-frequency operation.

Key Performance Metrics: RDS(on) and Switching Speed

Trench MOSFETs typically exhibit lower RDS(on) values than Planar MOSFETs due to their vertical channel structure, which reduces resistance and enhances current flow efficiency. The trench design also contributes to faster switching speed by minimizing gate charge and capacitance, allowing for quicker transitions between on and off states. Planar MOSFETs generally have higher RDS(on) and slower switching speeds, making trench MOSFETs preferable for high-efficiency and high-frequency power applications.

Efficiency Comparison: Power Losses and Thermal Management

Trench MOSFETs exhibit lower conduction and switching losses compared to Planar MOSFETs due to their vertical channel structure, which reduces on-resistance and gate charge. This efficiency results in improved thermal management, as lower power dissipation minimizes heat generation, allowing for more compact and reliable cooling solutions. Consequently, Trench MOSFETs are preferred in high-efficiency power electronics where reduced power losses and enhanced thermal performance are critical.

Breakdown Voltage and Safe Operating Area

Planar MOSFETs typically offer higher breakdown voltage due to their simpler surface structure, making them suitable for high-voltage applications. Trench MOSFETs provide a larger safe operating area (SOA) by reducing on-resistance and improving heat dissipation, which enhances reliability under high current stress. Selecting between them depends on your need for voltage tolerance versus efficiency and thermal performance.

Applications: Where Planar and Trench MOSFETs Excel

Planar MOSFETs excel in low-voltage, low-power applications such as small-signal switching, analog circuits, and integrated circuits due to their mature fabrication process and ease of integration. Trench MOSFETs dominate high-current, high-efficiency power conversion applications including DC-DC converters, automotive systems, and power supplies by offering lower on-resistance (R_DS(on)) and superior thermal performance. The trench structure enables higher cell density and reduced switching losses, making it ideal for demanding power management solutions.

Fabrication Processes and Design Complexity

Planar MOSFETs are manufactured using traditional semiconductor fabrication techniques involving photolithography and ion implantation on a flat silicon surface, which results in a simpler and more mature production process. Trench MOSFETs require more advanced fabrication steps, including deep reactive ion etching to form vertical trenches and precise doping profiles, leading to increased design complexity but enabling higher device density and performance. Your choice between the two depends on balancing the cost of manufacturing against the desired electrical characteristics and application requirements.

Cost Analysis: Manufacturing and Scalability

Planar MOSFETs typically have lower manufacturing costs due to their well-established fabrication processes and simpler designs, making them more scalable for high-volume production. Trench MOSFETs, while offering improved electrical performance and efficiency, require more complex manufacturing steps such as deep trench etching, which increases production costs and challenges scalability. Your choice between the two should consider the balance between initial cost savings of planar devices and the long-term efficiency gains from trench MOSFETs in large-scale applications.

Reliability and Longevity Considerations

Trench MOSFETs generally offer higher reliability and longer lifespan due to their lower on-resistance and better thermal performance, which reduces heat stress during operation. Planar MOSFETs, while simpler in design, may experience increased degradation under high current and temperature conditions because of higher channel resistance and reduced efficiency in heat dissipation. Advanced trench structures improve electron mobility and reduce hot spot formation, directly enhancing device longevity in demanding applications.

Conclusion: Choosing Between Planar and Trench MOSFET

Choosing between Planar MOSFET and Trench MOSFET depends on application-specific requirements such as switching speed, power density, and thermal performance. Trench MOSFETs offer lower on-resistance and higher current handling due to their vertical structure, making them ideal for high-efficiency power conversion. Planar MOSFETs provide simpler fabrication and better ruggedness in high-voltage applications but generally exhibit higher conduction losses.

Planar MOSFET vs Trench MOSFET Infographic

electrown.com

electrown.com