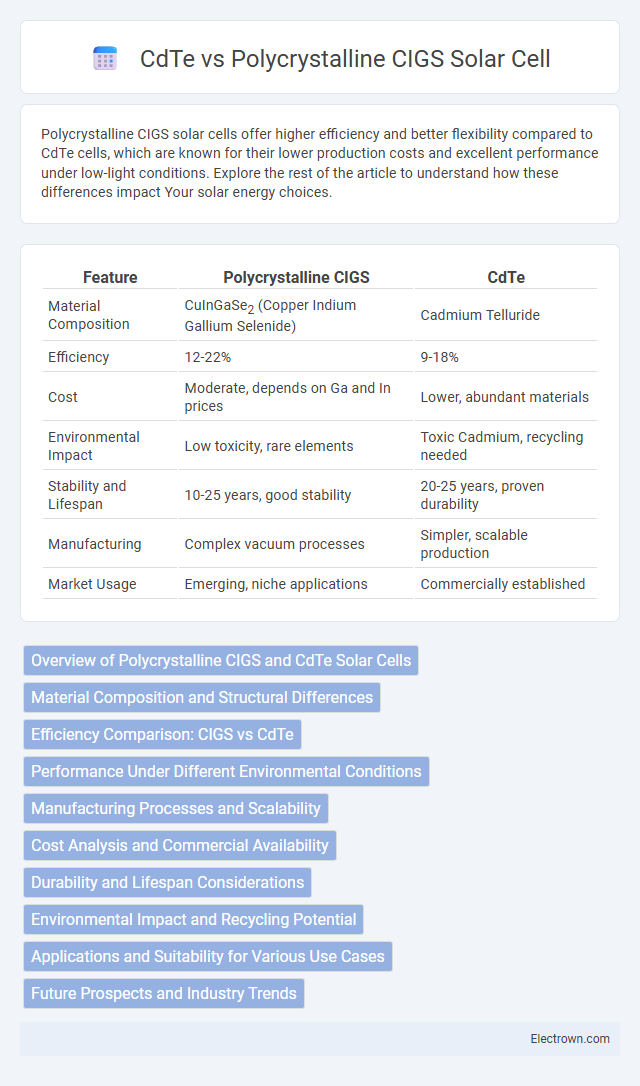

Polycrystalline CIGS solar cells offer higher efficiency and better flexibility compared to CdTe cells, which are known for their lower production costs and excellent performance under low-light conditions. Explore the rest of the article to understand how these differences impact Your solar energy choices.

Table of Comparison

| Feature | Polycrystalline CIGS | CdTe |

|---|---|---|

| Material Composition | CuInGaSe2 (Copper Indium Gallium Selenide) | Cadmium Telluride |

| Efficiency | 12-22% | 9-18% |

| Cost | Moderate, depends on Ga and In prices | Lower, abundant materials |

| Environmental Impact | Low toxicity, rare elements | Toxic Cadmium, recycling needed |

| Stability and Lifespan | 10-25 years, good stability | 20-25 years, proven durability |

| Manufacturing | Complex vacuum processes | Simpler, scalable production |

| Market Usage | Emerging, niche applications | Commercially established |

Overview of Polycrystalline CIGS and CdTe Solar Cells

Polycrystalline CIGS (Copper Indium Gallium Selenide) solar cells feature a layered structure with a semiconductor composed of a quaternary compound, enabling high absorption efficiency and flexibility on various substrates. CdTe (Cadmium Telluride) solar cells utilize a thin-film semiconductor layer with a direct bandgap around 1.45 eV, offering cost-effective manufacturing and competitive efficiency rates. Both technologies exhibit strong potential for scalable photovoltaic applications, balancing material abundance, efficiency, and production costs.

Material Composition and Structural Differences

Polycrystalline CIGS solar cells consist of copper indium gallium selenide, offering a tunable bandgap by adjusting the indium and gallium ratio, which enhances light absorption efficiency. CdTe solar cells use cadmium telluride as the semiconductor material, characterized by a simpler composition and a near-optimal bandgap for converting sunlight into electricity. Your choice between these technologies depends on the material properties, where CIGS provides flexibility in design, while CdTe benefits from cost-effective manufacturing.

Efficiency Comparison: CIGS vs CdTe

Polycrystalline CIGS solar cells typically achieve efficiencies around 15-22%, benefiting from high absorption coefficients and tunable bandgaps that optimize light harvesting. CdTe solar cells generally demonstrate efficiencies in the range of 18-21%, with robust performance in low-light conditions and lower production costs. Your choice between CIGS and CdTe can impact overall system efficiency based on specific application needs and environmental factors.

Performance Under Different Environmental Conditions

Polycrystalline CIGS solar cells demonstrate superior performance in low-light and shaded conditions due to their high absorption coefficient and flexibility, maintaining efficiency even at elevated temperatures. CdTe solar cells perform well under high irradiance and high-temperature environments, exhibiting excellent thermal stability and limited efficiency loss. Both technologies show resilience in diverse climates, but CIGS tends to outperform in variable light situations, whereas CdTe is favored for large-scale deployments in hot, sunny regions.

Manufacturing Processes and Scalability

Polycrystalline CIGS solar cells utilize a vacuum-based deposition process involving co-evaporation or sputtering, enabling high-quality thin films but requiring complex equipment that can limit large-scale production. CdTe solar cells benefit from a simpler, lower-cost manufacturing process using close-spaced sublimation or electrodeposition, which supports faster throughput and easier scalability for mass production. Your choice between these technologies depends on balancing manufacturing complexity against scalable production capacity and cost efficiency.

Cost Analysis and Commercial Availability

Polycrystalline CIGS solar cells generally have higher manufacturing costs due to complex fabrication processes involving rare materials like indium and gallium, whereas CdTe solar cells benefit from lower production costs with abundant tellurium supply. CdTe technology is more commercially available, dominated by companies like First Solar, enabling large-scale deployment and economies of scale that reduce module prices. Cost analysis indicates CdTe modules typically offer a more competitive price per watt compared to CIGS, driving broader adoption in utility-scale solar markets.

Durability and Lifespan Considerations

Polycrystalline CIGS solar cells typically offer superior durability and a longer lifespan compared to CdTe solar cells due to their enhanced resistance to environmental stressors such as moisture and temperature fluctuations. Your choice may depend on specific durability needs, as CdTe cells generally exhibit faster degradation rates under prolonged UV exposure, impacting long-term performance. Advanced encapsulation techniques can mitigate some lifespan concerns for both technologies, but CIGS remains favored for applications demanding sustained reliability.

Environmental Impact and Recycling Potential

Polycrystalline CIGS solar cells contain elements like indium and gallium, which are rare and pose challenges for recycling but have a lower toxicity profile compared to CdTe cells that contain cadmium, a heavy metal with significant environmental hazards. Recycling programs for CdTe panels focus on cadmium recovery and safe disposal, mitigating some risks but requiring stringent regulations due to its toxicity. The environmental impact of CIGS is generally considered lower due to less toxic materials, but efficient recycling methods for both types remain critical to reducing resource depletion and minimizing ecological footprint.

Applications and Suitability for Various Use Cases

Polycrystalline CIGS solar cells offer high efficiency and flexibility, making them ideal for portable devices, building-integrated photovoltaics (BIPV), and applications requiring lightweight panels. CdTe solar cells provide cost-effective energy solutions with strong performance in large-scale utility and commercial installations due to their lower manufacturing expenses and good temperature resilience. Your choice between CIGS and CdTe should consider factors like installation environment, budget constraints, and specific energy output requirements for optimal performance.

Future Prospects and Industry Trends

Polycrystalline CIGS solar cells exhibit promising future prospects due to their higher efficiency potential and flexibility, driving increased adoption in both residential and commercial markets. CdTe solar technology continues to benefit from lower manufacturing costs and scalability, maintaining its strong position in large-scale utility installations. Industry trends indicate growing investments in enhancing CIGS stability and interface engineering, while CdTe advances focus on material recycling and reducing cadmium toxicity to meet evolving environmental regulations.

Polycrystalline CIGS vs CdTe solar cell Infographic

electrown.com

electrown.com