BeO offers superior thermal conductivity and electrical insulation compared to AlN, making it ideal for high-performance electronic applications where efficient heat dissipation is critical. Explore the rest of the article to discover how these materials compare for your specific thermal management needs.

Table of Comparison

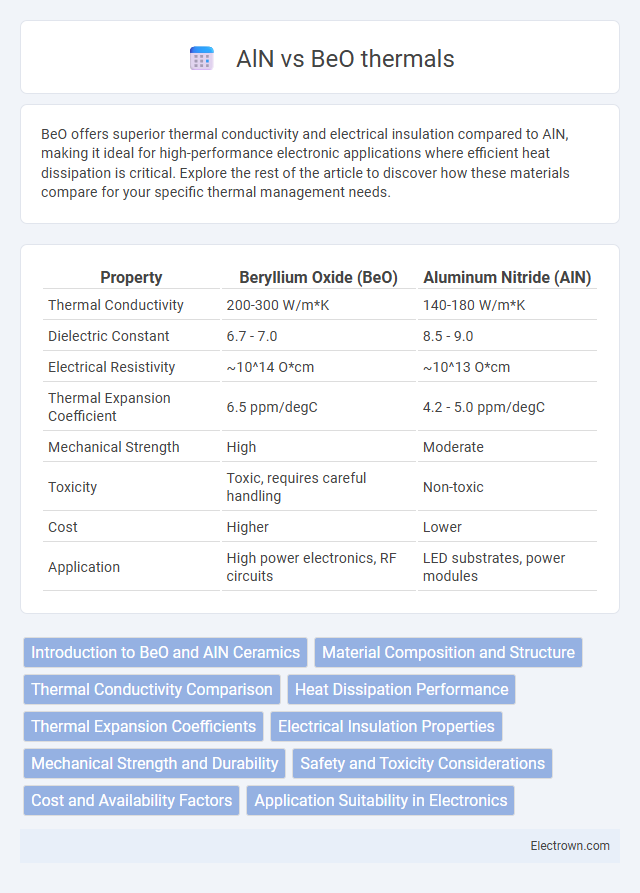

| Property | Beryllium Oxide (BeO) | Aluminum Nitride (AlN) |

|---|---|---|

| Thermal Conductivity | 200-300 W/m*K | 140-180 W/m*K |

| Dielectric Constant | 6.7 - 7.0 | 8.5 - 9.0 |

| Electrical Resistivity | ~10^14 O*cm | ~10^13 O*cm |

| Thermal Expansion Coefficient | 6.5 ppm/degC | 4.2 - 5.0 ppm/degC |

| Mechanical Strength | High | Moderate |

| Toxicity | Toxic, requires careful handling | Non-toxic |

| Cost | Higher | Lower |

| Application | High power electronics, RF circuits | LED substrates, power modules |

Introduction to BeO and AlN Ceramics

Beryllium oxide (BeO) and aluminum nitride (AlN) ceramics are renowned for their exceptional thermal conductivity, making them ideal for electronic packaging and heat dissipation applications. BeO offers thermal conductivities up to 330 W/m*K, surpassing many ceramic materials, while AlN provides excellent thermal stability with conductivities around 170-230 W/m*K. Both ceramics combine electrical insulation with high thermal performance, but BeO's toxicity concerns have led to increased use of AlN in modern thermal management solutions.

Material Composition and Structure

Beryllium Oxide (BeO) is a ceramic compound consisting of beryllium and oxygen atoms arranged in a hexagonal crystal lattice, imparting high thermal conductivity and electrical insulation. Aluminum Nitride (AlN) features a wurtzite crystal structure formed by aluminum and nitrogen atoms, offering comparable thermal performance with enhanced electrical insulation and chemical stability. The intrinsic bonding and lattice structures of BeO enable thermal conductivities up to 330 W/m*K, while AlN exhibits thermal conductivity around 170-230 W/m*K, influenced by purity and fabrication methods.

Thermal Conductivity Comparison

Beryllium Oxide (BeO) exhibits a thermal conductivity typically around 200-330 W/m*K, significantly outperforming Aluminum Nitride (AlN), which generally ranges between 140-180 W/m*K. The superior thermal conductivity of BeO makes it an excellent choice for applications requiring efficient heat dissipation, such as high-power electronics and RF devices. Your selection depends on balancing thermal performance with other factors like electrical insulation and material safety, where AlN may offer advantages despite its lower conductivity.

Heat Dissipation Performance

Beryllium oxide (BeO) exhibits superior heat dissipation performance with a thermal conductivity of approximately 250-330 W/m*K, significantly outperforming aluminum nitride (AlN), which typically offers around 140-180 W/m*K. This high thermal conductivity makes BeO ideal for applications requiring rapid heat transfer and efficient thermal management, such as high-power electronics and LEDs. Despite AlN's lower thermal conductivity, it remains popular due to its electrical insulation properties and better safety profile compared to BeO.

Thermal Expansion Coefficients

Beryllium Oxide (BeO) exhibits a thermal expansion coefficient of approximately 7.4 x 10^-6 /degC, which is closely matched to silicon, making it ideal for minimizing thermal stress in electronic packages. Aluminum Nitride (AlN) has a slightly higher thermal expansion coefficient around 4.5 to 5.5 x 10^-6 /degC, providing good thermal compatibility with many semiconductor materials. Your choice between BeO and AlN should consider the thermal expansion to ensure reliable performance and mechanical stability in thermal management applications.

Electrical Insulation Properties

BeO (beryllium oxide) offers excellent electrical insulation properties with high dielectric strength and low electrical conductivity, making it ideal for high-voltage electronic applications. AlN (aluminum nitride) also provides strong electrical insulation but with slightly lower dielectric strength compared to BeO, although it excels in thermal conductivity. Your choice depends on balancing the need for electrical insulation with thermal management requirements in electronic device design.

Mechanical Strength and Durability

Beryllium oxide (BeO) exhibits superior mechanical strength with a high flexural strength around 400 MPa, offering excellent durability under thermal stress compared to aluminum nitride (AlN). AlN possesses a flexural strength typically between 200-350 MPa but excels in fracture toughness and resistance to thermal shock, making it reliable for demanding applications. Both materials demonstrate robust mechanical properties, but BeO's higher strength favors long-term structural integrity, while AlN's durability supports high-reliability electronic packaging.

Safety and Toxicity Considerations

Beryllium oxide (BeO) offers superior thermal conductivity compared to aluminum nitride (AlN) but poses significant safety risks due to its toxic beryllium dust, which can cause chronic beryllium disease upon inhalation. Aluminum nitride is considered safer with no known carcinogenic effects and lower toxicity, making it preferable for applications requiring handling and machining with minimal health hazards. Proper industrial hygiene and protective measures are mandatory when working with BeO to mitigate exposure risks, whereas AlN requires standard precautions.

Cost and Availability Factors

Beryllium oxide (BeO) offers superior thermal conductivity compared to aluminum nitride (AlN), but its higher cost and limited availability restrict widespread use in budget-sensitive applications. AlN provides a more cost-effective solution with easier sourcing and comparable thermal performance, making it a preferred choice for many industries. When selecting between BeO and AlN, your decision should weigh the premium price of BeO against the accessible, abundant supply and better cost-efficiency of AlN.

Application Suitability in Electronics

Beryllium Oxide (BeO) exhibits superior thermal conductivity around 330 W/mK, making it highly suitable for high-power electronic devices requiring efficient heat dissipation and compact designs. Aluminum Nitride (AlN) offers thermal conductivity typically between 140-180 W/mK and provides excellent electrical insulation, ideal for applications needing a balance between thermal management and electrical isolation in LED substrates and RF devices. Both materials support improved device reliability and performance, with BeO favored in extreme thermal environments, while AlN is preferred for environmentally safer, high-frequency electronic packaging.

BeO vs AlN thermals Infographic

electrown.com

electrown.com