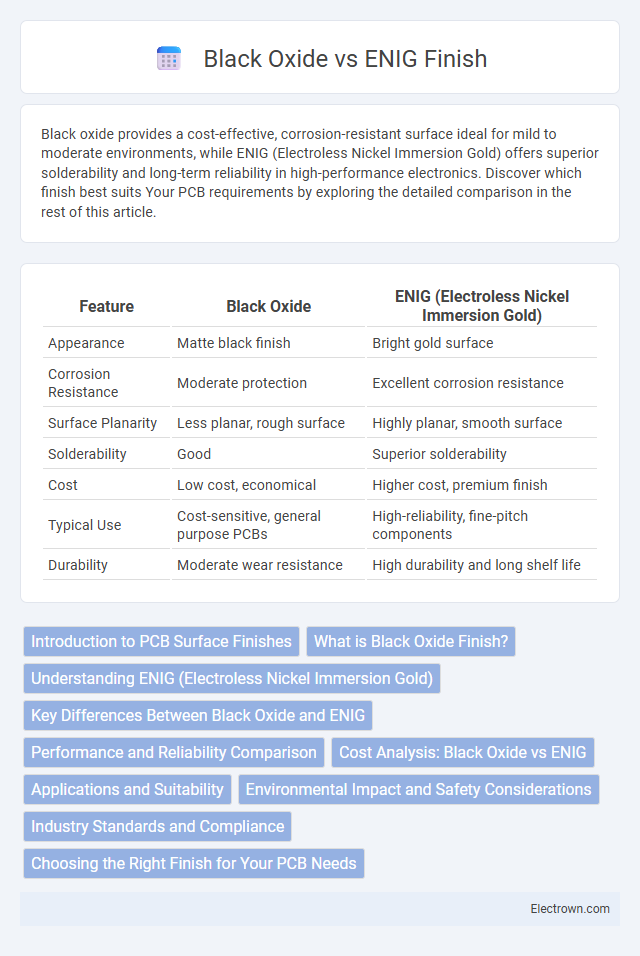

Black oxide provides a cost-effective, corrosion-resistant surface ideal for mild to moderate environments, while ENIG (Electroless Nickel Immersion Gold) offers superior solderability and long-term reliability in high-performance electronics. Discover which finish best suits Your PCB requirements by exploring the detailed comparison in the rest of this article.

Table of Comparison

| Feature | Black Oxide | ENIG (Electroless Nickel Immersion Gold) |

|---|---|---|

| Appearance | Matte black finish | Bright gold surface |

| Corrosion Resistance | Moderate protection | Excellent corrosion resistance |

| Surface Planarity | Less planar, rough surface | Highly planar, smooth surface |

| Solderability | Good | Superior solderability |

| Cost | Low cost, economical | Higher cost, premium finish |

| Typical Use | Cost-sensitive, general purpose PCBs | High-reliability, fine-pitch components |

| Durability | Moderate wear resistance | High durability and long shelf life |

Introduction to PCB Surface Finishes

Black oxide and ENIG finishes serve distinct purposes in PCB surface treatments, impacting performance and durability. ENIG (Electroless Nickel Immersion Gold) provides excellent solderability with corrosion resistance and a flat surface ideal for fine-pitch components, while black oxide offers improved adhesion for epoxy materials and is often used in thermal management. Choosing the right finish depends on your PCB's application requirements, including environmental exposure and assembly processes.

What is Black Oxide Finish?

Black oxide finish is a chemical conversion coating applied to metal surfaces, primarily steel, to enhance corrosion resistance, reduce light reflection, and improve lubricity. This finish forms a black, matte layer that minimizes wear and provides a uniform appearance without adding significant thickness. Your components benefit from increased durability and mild corrosion protection thanks to its compact, tightly bonded oxide layer.

Understanding ENIG (Electroless Nickel Immersion Gold)

ENIG (Electroless Nickel Immersion Gold) finish offers superior corrosion resistance and excellent solderability compared to black oxide, making it ideal for high-reliability printed circuit boards (PCBs). This finish consists of a nickel layer that provides a robust barrier, topped with a thin layer of immersion gold to protect the nickel and enhance electrical conductivity. Your choice of ENIG ensures better surface planarity and longer shelf-life for complex PCB assemblies requiring fine-pitch components.

Key Differences Between Black Oxide and ENIG

Black oxide finish provides a thin, matte black surface layer that enhances corrosion resistance and electrical conductivity, typically used for cost-effective protection in steel parts. ENIG (Electroless Nickel Immersion Gold) offers superior surface flatness, excellent oxidation resistance, and high solderability, making it ideal for complex printed circuit boards requiring reliable electronic performance. Your choice depends on whether durability and conductivity in metal components or high-precision, long-lasting PCB finishes are prioritized.

Performance and Reliability Comparison

Black oxide finish offers moderate corrosion resistance and good solderability, making it suitable for applications where cost-efficiency and ease of soldering are priorities. ENIG (Electroless Nickel Immersion Gold) finish provides superior corrosion resistance, excellent planarity, and consistent electrical performance, enhancing long-term reliability in high-density and fine-pitch circuit boards. ENIG's nickel layer acts as a robust barrier against oxidation, while the thin gold layer ensures a highly solderable, durable surface, outperforming black oxide in harsh environmental conditions.

Cost Analysis: Black Oxide vs ENIG

Black oxide finish generally offers a lower-cost solution compared to Electroless Nickel Immersion Gold (ENIG) due to simpler processing and reduced material expenses, making it suitable for budget-sensitive PCB manufacturing. ENIG finish involves higher costs driven by the use of precious metals like gold and nickel, which provide superior corrosion resistance, solderability, and shelf life, justifying the premium for high-reliability applications. Cost analysis favors black oxide for economic projects, while ENIG's investment supports performance-critical electronics requiring enhanced durability and surface quality.

Applications and Suitability

Black oxide finish provides excellent corrosion resistance and electrical conductivity, making it ideal for aerospace and military applications where durability and performance are critical. ENIG (Electroless Nickel Immersion Gold) finish offers superior surface planarity and excellent solderability, suited for high-density PCB assemblies in consumer electronics and telecommunications. ENIG also ensures reliable wire bonding and is preferred in applications requiring fine-pitch components and long-term storage stability.

Environmental Impact and Safety Considerations

Black oxide finish offers an environmentally friendly option by avoiding the use of heavy metals and hazardous chemicals, reducing toxic waste and lowering health risks during manufacturing. ENIG (Electroless Nickel Immersion Gold) finish involves the use of nickel and gold, which require careful handling and disposal to minimize environmental contamination and worker exposure. You should weigh the eco-friendliness of black oxide against the premium corrosion resistance and conductivity benefits of ENIG while considering your sustainability goals and safety protocols.

Industry Standards and Compliance

Black oxide and ENIG finishes adhere to distinct industry standards critical for ensuring reliability in electronic manufacturing. Black oxide is valued for its cost-effectiveness and excellent solderability, meeting IPC-4552 standards for corrosion resistance and electrical performance in rugged applications. ENIG, meeting IPC-4557 standards, provides superior surface planarity, excellent oxidation resistance, and long shelf-life, often preferred in high-frequency and fine-pitch PCB designs where compliance with stringent industry regulations is essential for Your product's durability and performance.

Choosing the Right Finish for Your PCB Needs

Black oxide offers excellent solderability and corrosion resistance for PCBs with cost-effective performance, while ENIG (Electroless Nickel Immersion Gold) provides superior surface planarity, enhanced conductivity, and long-term oxidation protection. Your choice depends on factors such as budget constraints, desired electrical performance, and environmental durability required for the specific application. Prioritize ENIG for high-reliability, fine-pitch components, and black oxide for general-purpose, cost-sensitive PCB assemblies.

black oxide vs ENIG finish Infographic

electrown.com

electrown.com