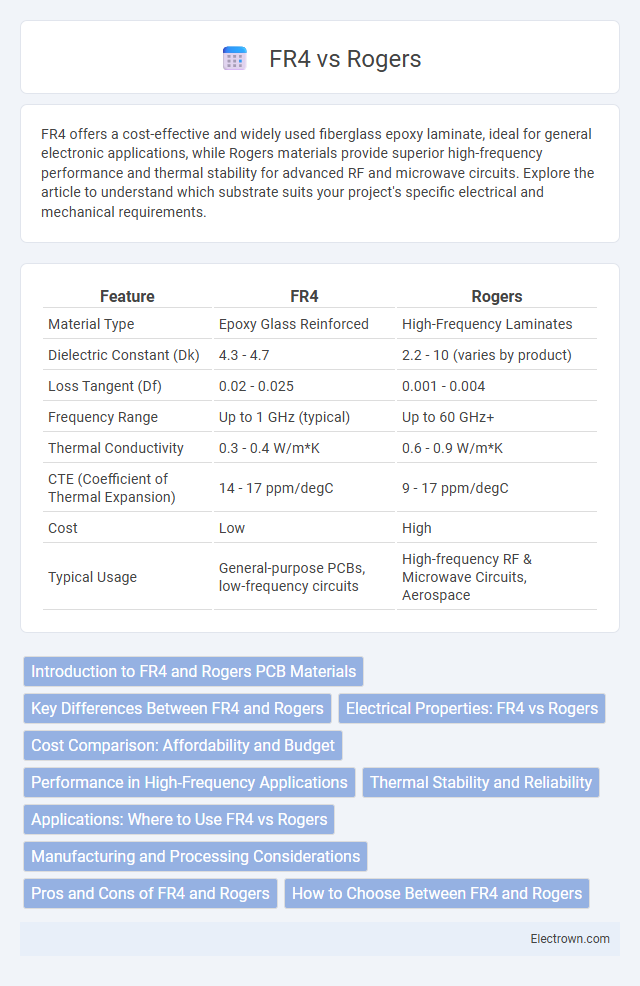

FR4 offers a cost-effective and widely used fiberglass epoxy laminate, ideal for general electronic applications, while Rogers materials provide superior high-frequency performance and thermal stability for advanced RF and microwave circuits. Explore the article to understand which substrate suits your project's specific electrical and mechanical requirements.

Table of Comparison

| Feature | FR4 | Rogers |

|---|---|---|

| Material Type | Epoxy Glass Reinforced | High-Frequency Laminates |

| Dielectric Constant (Dk) | 4.3 - 4.7 | 2.2 - 10 (varies by product) |

| Loss Tangent (Df) | 0.02 - 0.025 | 0.001 - 0.004 |

| Frequency Range | Up to 1 GHz (typical) | Up to 60 GHz+ |

| Thermal Conductivity | 0.3 - 0.4 W/m*K | 0.6 - 0.9 W/m*K |

| CTE (Coefficient of Thermal Expansion) | 14 - 17 ppm/degC | 9 - 17 ppm/degC |

| Cost | Low | High |

| Typical Usage | General-purpose PCBs, low-frequency circuits | High-frequency RF & Microwave Circuits, Aerospace |

Introduction to FR4 and Rogers PCB Materials

FR4 is a widely used, cost-effective epoxy resin and woven fiberglass composite offering reliable electrical insulation and mechanical strength in printed circuit boards (PCBs). Rogers PCB materials, made from advanced hydrocarbon ceramics or PTFE composites, provide superior dielectric properties, low signal loss, and enhanced thermal management for high-frequency and high-performance applications. Understanding the differences in dielectric constant, thermal conductivity, and loss tangent between FR4 and Rogers helps you select the optimal substrate for your PCB design requirements.

Key Differences Between FR4 and Rogers

FR4 is a widely used, cost-effective epoxy resin fiberglass laminate known for its mechanical strength and general-purpose applications, while Rogers materials offer advanced dielectric properties and low loss suitable for high-frequency and high-performance circuits. You should consider FR4 for standard PCB needs where budget is a priority, whereas Rogers substrates excel in RF, microwave, and high-speed digital designs requiring superior thermal stability and signal integrity. Key differences include dielectric constant, thermal conductivity, and signal attenuation, with Rogers providing better performance at higher frequencies compared to FR4's more general electrical properties.

Electrical Properties: FR4 vs Rogers

FR4 offers a dielectric constant (Dk) of around 4.5 with a loss tangent typically between 0.02 and 0.03, making it suitable for general-purpose PCB applications but less effective at high frequencies. Rogers materials provide superior electrical performance with lower dielectric constants often ranging from 3.0 to 3.5 and exceptionally low loss tangents around 0.001 to 0.005, optimizing signal integrity and minimizing dielectric losses in high-frequency and RF circuits. The significantly lower dissipation factor in Rogers laminates translates to higher signal propagation speeds and improved overall electrical performance compared to traditional FR4 substrates.

Cost Comparison: Affordability and Budget

FR4 offers a highly affordable solution for printed circuit boards, making it ideal for budget-conscious projects without sacrificing basic performance. Rogers materials, while significantly more expensive, provide superior electrical properties and thermal stability critical for high-frequency and high-performance applications. Your choice depends on balancing cost-efficiency with the specific technical requirements of your design.

Performance in High-Frequency Applications

Rogers laminates exhibit superior dielectric properties and low loss tangent, making them ideal for high-frequency applications such as RF and microwave circuits, where signal integrity and minimal insertion loss are critical. FR4, while cost-effective and widely used, has higher dielectric constant variability and greater signal loss, limiting its performance in frequencies above 1 GHz. Your choice between FR4 and Rogers impacts the efficiency and reliability of high-frequency designs, with Rogers preferred for advanced communication systems and high-speed signal transmission.

Thermal Stability and Reliability

FR4 exhibits moderate thermal stability with a glass transition temperature (Tg) typically around 130-140degC, making it suitable for standard applications but less reliable under high-temperature conditions. Rogers materials offer superior thermal stability, with Tg values ranging from 180degC to over 280degC, ensuring enhanced performance and reliability in high-frequency and high-temperature environments. Choosing Rogers for your PCB ensures greater resistance to thermal degradation and improved long-term reliability in demanding conditions.

Applications: Where to Use FR4 vs Rogers

FR4 is ideal for standard PCB applications in consumer electronics, automotive, and industrial equipment due to its cost-effectiveness and good mechanical strength. Rogers materials excel in high-frequency and high-performance RF/microwave circuits used in telecommunications, aerospace, and military applications, where low dielectric loss and stable electrical properties are critical. Choose FR4 for general-purpose designs and Rogers for advanced applications requiring superior signal integrity and thermal management.

Manufacturing and Processing Considerations

FR4 offers cost-effective manufacturing with excellent mechanical strength and easy compatibility with standard PCB fabrication processes like drilling and soldering. Rogers materials, designed for high-frequency applications, require specialized processing due to their unique dielectric properties and often involve tighter tolerances and controlled lamination cycles. The choice between FR4 and Rogers impacts production complexity, yield rates, and overall fabrication costs depending on frequency performance and precision requirements.

Pros and Cons of FR4 and Rogers

FR4 offers cost-effective manufacturing and good mechanical strength, making it ideal for most standard PCB applications, but it has higher dielectric loss and limited high-frequency performance compared to Rogers. Rogers materials provide superior electrical properties, such as low dielectric constant and low loss tangent, crucial for high-frequency and RF circuits, yet come with higher costs and less mechanical durability. Your choice depends on balancing budget constraints with performance requirements in high-frequency designs.

How to Choose Between FR4 and Rogers

Choosing between FR4 and Rogers depends on the specific performance requirements and application environment of the PCB. FR4 offers cost-effective mechanical strength and moderate electrical insulation, making it suitable for standard consumer electronics, while Rogers laminates provide superior dielectric properties, low signal loss, and thermal stability essential for high-frequency RF and microwave circuits. Evaluating factors such as operating frequency, signal integrity, thermal management, and budget constraints ensures the best match between material capabilities and project demands.

FR4 vs Rogers Infographic

electrown.com

electrown.com