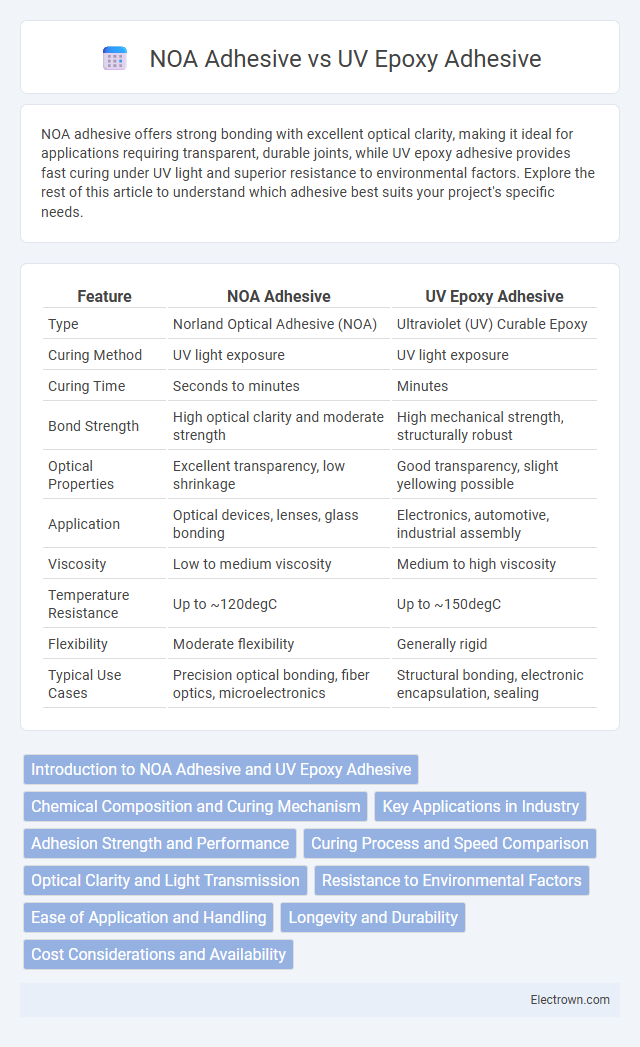

NOA adhesive offers strong bonding with excellent optical clarity, making it ideal for applications requiring transparent, durable joints, while UV epoxy adhesive provides fast curing under UV light and superior resistance to environmental factors. Explore the rest of this article to understand which adhesive best suits your project's specific needs.

Table of Comparison

| Feature | NOA Adhesive | UV Epoxy Adhesive |

|---|---|---|

| Type | Norland Optical Adhesive (NOA) | Ultraviolet (UV) Curable Epoxy |

| Curing Method | UV light exposure | UV light exposure |

| Curing Time | Seconds to minutes | Minutes |

| Bond Strength | High optical clarity and moderate strength | High mechanical strength, structurally robust |

| Optical Properties | Excellent transparency, low shrinkage | Good transparency, slight yellowing possible |

| Application | Optical devices, lenses, glass bonding | Electronics, automotive, industrial assembly |

| Viscosity | Low to medium viscosity | Medium to high viscosity |

| Temperature Resistance | Up to ~120degC | Up to ~150degC |

| Flexibility | Moderate flexibility | Generally rigid |

| Typical Use Cases | Precision optical bonding, fiber optics, microelectronics | Structural bonding, electronic encapsulation, sealing |

Introduction to NOA Adhesive and UV Epoxy Adhesive

NOA adhesive, or Norland Optical Adhesive, is a UV-curable adhesive widely used in optical and electronic applications for its fast curing under UV light and strong bonding capabilities on glass and plastics. UV epoxy adhesive combines UV light curing with epoxy resin properties, offering enhanced mechanical strength, chemical resistance, and durability for demanding industrial uses. Both adhesives rapidly cure under UV exposure but differ in chemical composition and performance characteristics suited to specific bonding requirements.

Chemical Composition and Curing Mechanism

NOA adhesive typically consists of aliphatic urethane acrylates that cure through UV light-induced free radical polymerization, resulting in rapid hardening and strong bonding. UV epoxy adhesive is formulated from epoxy resins that cure via cationic polymerization triggered by UV exposure, offering excellent chemical resistance and durability. Your choice depends on specific application needs, as NOA adhesives provide flexibility and quick curing, while UV epoxy adhesives yield superior mechanical strength and environmental stability.

Key Applications in Industry

NOA adhesive is widely used in precision optics manufacturing, medical device assembly, and sensitive electronics due to its excellent UV curing properties and low shrinkage. UV epoxy adhesive excels in automotive, aerospace, and heavy industrial applications for its superior mechanical strength and resistance to harsh environmental conditions. Both adhesives play crucial roles in industries requiring rapid curing and durable bonding solutions.

Adhesion Strength and Performance

NOA adhesive offers superior adhesion strength on glass and optical components, providing excellent durability in precise applications. UV epoxy adhesive cures quickly under ultraviolet light, ensuring strong bonding with fast setup times ideal for high-volume production. Your choice depends on whether you prioritize long-term performance or rapid assembly in your project.

Curing Process and Speed Comparison

NOA adhesive cures primarily through exposure to ultraviolet (UV) light, achieving rapid hardening within seconds once activated, making it ideal for quick assembly processes. UV epoxy adhesive combines UV curing with an additional chemical curing mechanism, which can provide stronger bonds but typically requires longer curing times or supplemental heat. Your choice between NOA adhesive and UV epoxy adhesive depends on whether speed or ultimate bond strength is the priority in your application.

Optical Clarity and Light Transmission

NOA adhesive offers exceptional optical clarity with high light transmission rates, making it ideal for precision optics and display applications where minimal light distortion is critical. UV epoxy adhesive provides strong bonding and good clarity, but typically exhibits slightly lower light transmission compared to NOA, which can affect performance in highly sensitive optical devices. Your choice should prioritize NOA adhesive when maximum transparency and minimal light interference are essential for optimal device functionality.

Resistance to Environmental Factors

NOA adhesives exhibit superior resistance to environmental factors such as moisture, temperature fluctuations, and UV exposure, maintaining strong bonding integrity in harsh conditions. UV epoxy adhesives offer durable bonds but tend to degrade faster under prolonged UV radiation and high humidity. Choosing NOA adhesives ensures enhanced longevity and reliability in outdoor or industrial applications exposed to adverse environments.

Ease of Application and Handling

NOA adhesive offers superior ease of application with its lower viscosity, allowing precise control and smooth spreading on delicate surfaces. UV epoxy adhesive requires careful mixing and curing under UV light, which may complicate handling and extend processing time. For rapid setting and straightforward use, NOA adhesive is often preferred in high-precision bonding tasks.

Longevity and Durability

NOA adhesives typically offer superior longevity due to their strong chemical resistance and flexibility, making them ideal for long-term applications in various environmental conditions. UV epoxy adhesives provide excellent durability with high mechanical strength and resistance to wear, but their lifespan can be limited by UV exposure and potential yellowing over time. Choosing between NOA and UV epoxy depends on the specific durability requirements and environmental factors of the intended use.

Cost Considerations and Availability

NOA adhesive typically costs less than UV epoxy adhesive, making it a budget-friendly option for large-volume applications. UV epoxy adhesives, while more expensive, offer superior strength and durability, often justifying the higher price in specialized uses. Your choice should consider both the initial cost and the availability of these adhesives through local suppliers or online distributors.

NOA adhesive vs UV epoxy adhesive Infographic

electrown.com

electrown.com