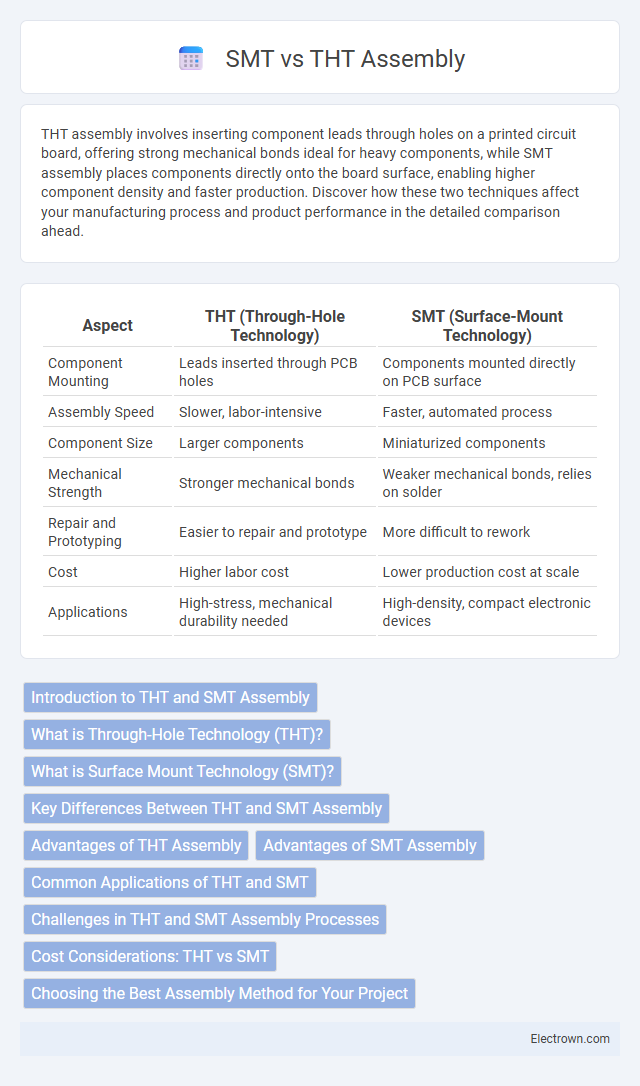

THT assembly involves inserting component leads through holes on a printed circuit board, offering strong mechanical bonds ideal for heavy components, while SMT assembly places components directly onto the board surface, enabling higher component density and faster production. Discover how these two techniques affect your manufacturing process and product performance in the detailed comparison ahead.

Table of Comparison

| Aspect | THT (Through-Hole Technology) | SMT (Surface-Mount Technology) |

|---|---|---|

| Component Mounting | Leads inserted through PCB holes | Components mounted directly on PCB surface |

| Assembly Speed | Slower, labor-intensive | Faster, automated process |

| Component Size | Larger components | Miniaturized components |

| Mechanical Strength | Stronger mechanical bonds | Weaker mechanical bonds, relies on solder |

| Repair and Prototyping | Easier to repair and prototype | More difficult to rework |

| Cost | Higher labor cost | Lower production cost at scale |

| Applications | High-stress, mechanical durability needed | High-density, compact electronic devices |

Introduction to THT and SMT Assembly

THT (Through-Hole Technology) assembly involves inserting electronic components with leads through pre-drilled holes on a printed circuit board (PCB) and soldering them on the opposite side for strong mechanical bonds and reliable connections. SMT (Surface Mount Technology) assembly places smaller components directly onto the PCB surface, enabling higher component density, faster production, and better performance for modern electronics. Your choice between THT and SMT depends on factors like component size, assembly speed, and the desired durability of the final product.

What is Through-Hole Technology (THT)?

Through-Hole Technology (THT) is a method of mounting electronic components by inserting their leads through pre-drilled holes on a printed circuit board (PCB) and soldering them on the opposite side. This technique provides strong mechanical bonds and is ideal for components subjected to mechanical stress or heat. Your choice of THT ensures reliable connections for circuits requiring durability and ease of prototyping or repair.

What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a modern electronic assembly method where components are mounted directly onto the surface of printed circuit boards (PCBs), enabling higher component density and automated placement. Unlike Through-Hole Technology (THT), SMT uses smaller, lightweight components called surface-mount devices (SMDs), which improve electrical performance and allow for more compact designs. Your electronic manufacturing process benefits from faster production cycles and reduced costs when utilizing SMT for complex, high-volume assemblies.

Key Differences Between THT and SMT Assembly

THT (Through-Hole Technology) assembly involves inserting component leads through holes on a PCB and soldering them on the opposite side, providing strong mechanical bonds ideal for heavy or high-stress components. SMT (Surface-Mount Technology) assembly attaches components directly onto the PCB surface, allowing higher component density and automated, faster production processes. Your choice between THT and SMT assembly impacts manufacturing costs, board size, and application suitability, with SMT favored for miniaturization and mass production, while THT is preferred for durability and prototyping.

Advantages of THT Assembly

Through-Hole Technology (THT) assembly offers superior mechanical strength and durability compared to Surface-Mount Technology (SMT), making it ideal for components that undergo physical stress or high thermal cycles. THT components provide reliable electrical connections with enhanced heat dissipation capabilities, improving overall circuit stability. The ease of manual inspection and rework in THT assembly allows for better quality control in prototype and low-volume production stages.

Advantages of SMT Assembly

SMT assembly offers higher component density, enabling more compact and lightweight electronic designs. The automated process used in SMT reduces production time and labor costs, improving overall manufacturing efficiency. You benefit from enhanced electrical performance and reliability due to shorter lead lengths and improved signal integrity.

Common Applications of THT and SMT

THT (Through-Hole Technology) assembly is commonly used in applications requiring high mechanical strength and durability, such as automotive electronics, aerospace, and industrial equipment. SMT (Surface-Mount Technology) assembly dominates in consumer electronics, smartphones, and compact devices due to its efficiency in automated production and suitability for high-density circuit boards. Your choice between THT and SMT depends on the product's mechanical requirements and production scale.

Challenges in THT and SMT Assembly Processes

THT assembly faces challenges such as manual insertion difficulties, longer production cycles, and limited component density on printed circuit boards (PCBs). SMT assembly struggles with precise placement of tiny components, solder paste inspection, and thermal profile control during reflow soldering. Both processes require strict quality control to minimize defects like solder bridges, tombstoning, and misalignment.

Cost Considerations: THT vs SMT

THT assembly typically incurs higher costs due to manual labor and longer production times compared to the highly automated SMT process. SMT reduces overall expenses by enabling smaller, lighter components and facilitating mass production with lower labor input. Your choice between THT and SMT should factor in budget constraints alongside production volume and product complexity.

Choosing the Best Assembly Method for Your Project

Choosing between Through-Hole Technology (THT) and Surface Mount Technology (SMT) assembly methods depends on project requirements such as component size, mechanical strength, and production volume. THT provides superior mechanical stability for heavy components and is ideal for prototyping or low-volume runs, while SMT supports higher component density and automated assembly suited for mass production. Evaluating factors like cost, reliability, and board complexity ensures selecting the optimal assembly method tailored to your project's performance and budget needs.

THT vs SMT assembly Infographic

electrown.com

electrown.com