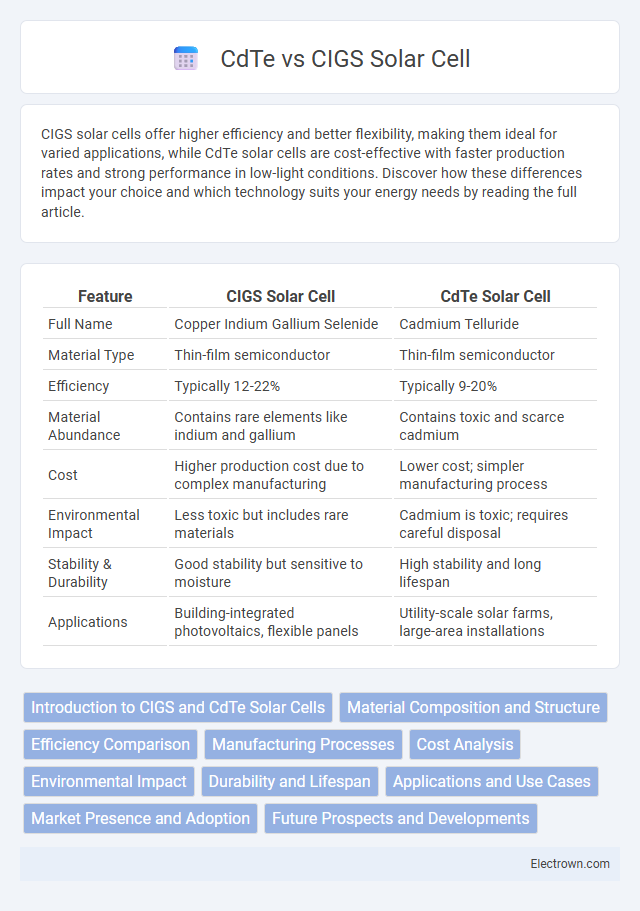

CIGS solar cells offer higher efficiency and better flexibility, making them ideal for varied applications, while CdTe solar cells are cost-effective with faster production rates and strong performance in low-light conditions. Discover how these differences impact your choice and which technology suits your energy needs by reading the full article.

Table of Comparison

| Feature | CIGS Solar Cell | CdTe Solar Cell |

|---|---|---|

| Full Name | Copper Indium Gallium Selenide | Cadmium Telluride |

| Material Type | Thin-film semiconductor | Thin-film semiconductor |

| Efficiency | Typically 12-22% | Typically 9-20% |

| Material Abundance | Contains rare elements like indium and gallium | Contains toxic and scarce cadmium |

| Cost | Higher production cost due to complex manufacturing | Lower cost; simpler manufacturing process |

| Environmental Impact | Less toxic but includes rare materials | Cadmium is toxic; requires careful disposal |

| Stability & Durability | Good stability but sensitive to moisture | High stability and long lifespan |

| Applications | Building-integrated photovoltaics, flexible panels | Utility-scale solar farms, large-area installations |

Introduction to CIGS and CdTe Solar Cells

CIGS (Copper Indium Gallium Selenide) and CdTe (Cadmium Telluride) solar cells represent two prominent thin-film photovoltaic technologies known for high efficiency and cost-effectiveness. CIGS solar cells offer tunable bandgap energy through varying indium and gallium ratios, enhancing absorption across the solar spectrum, while CdTe cells provide a near-optimal bandgap of approximately 1.45 eV, maximizing photon absorption and conversion efficiency. Both technologies exhibit strong potential for large-scale utility deployment due to their lightweight, flexible substrates and lower material consumption compared to traditional silicon solar panels.

Material Composition and Structure

CIGS solar cells consist of Copper, Indium, Gallium, and Selenium, forming a chalcogenide thin-film absorber layer that offers high absorption efficiency and tunable bandgap properties. In contrast, CdTe solar cells use Cadmium Telluride as the primary semiconductor layer, which provides a simpler material structure with a direct bandgap closely matched to the solar spectrum for effective photon absorption. Your choice between CIGS and CdTe depends on desired flexibility, manufacturing complexity, and performance in varying light conditions.

Efficiency Comparison

CIGS (Copper Indium Gallium Selenide) solar cells typically achieve higher efficiency rates, reaching up to 23%, compared to CdTe (Cadmium Telluride) solar cells, which generally max out around 21%. The superior efficiency of CIGS is attributed to its tunable bandgap and better light absorption properties. However, CdTe maintains cost-effectiveness and simpler manufacturing processes, making it competitive despite slightly lower efficiency.

Manufacturing Processes

CIGS solar cells utilize a complex manufacturing process involving co-evaporation or sputtering of copper, indium, gallium, and selenium layers, followed by a high-temperature annealing step to form the absorber layer. CdTe solar cells are typically produced using close-spaced sublimation (CSS) or vapor transport deposition (VTD) techniques, allowing rapid deposition of the cadmium telluride layer at relatively lower temperatures. Both technologies emphasize cost-effective, scalable thin-film production methods but differ significantly in raw material handling and thermal processing conditions.

Cost Analysis

Cost analysis reveals that CIGS (Copper Indium Gallium Selenide) solar cells often have higher manufacturing expenses due to complex material processing and lower material abundance compared to CdTe (Cadmium Telluride) solar cells. CdTe technology benefits from lower raw material costs and simpler, scalable production methods, leading to more competitive pricing per watt. For your solar investment, CdTe solar panels may offer better cost-efficiency, especially in large-scale installations.

Environmental Impact

CIGS solar cells exhibit lower toxicity due to the absence of cadmium, reducing environmental risks associated with hazardous heavy metals, whereas CdTe solar cells contain cadmium, which poses challenges in safe disposal and recycling processes. The manufacturing of CIGS panels typically involves less energy-intensive processes, contributing to a smaller carbon footprint compared to CdTe cells. End-of-life management is critical for both technologies, but CdTe requires stringent handling to prevent cadmium leaching, making CIGS a more environmentally benign option in sustainable solar energy production.

Durability and Lifespan

CIGS (Copper Indium Gallium Selenide) solar cells exhibit high durability due to their flexible substrate options and resistance to mechanical stress, contributing to a typical lifespan of 20-25 years. CdTe (Cadmium Telluride) solar cells are known for their robust performance in diverse environmental conditions, with a lifespan often reaching 25-30 years. Both technologies offer competitive longevity, but CdTe cells tend to have slightly better degradation resistance under prolonged exposure to moisture and temperature fluctuations.

Applications and Use Cases

CIGS solar cells excel in flexible and lightweight applications, making them ideal for building-integrated photovoltaics (BIPV) and portable solar devices due to their high efficiency and adaptability. CdTe solar cells dominate utility-scale solar farms because of their low production costs and superior performance under low-light and high-temperature conditions. Both technologies serve complementary roles, with CIGS favored for niche applications requiring flexibility and CdTe optimized for large-scale energy generation.

Market Presence and Adoption

CIGS solar cells, known for their flexibility and high efficiency, have gained significant market traction in niche applications like building-integrated photovoltaics (BIPV) and portable devices. CdTe solar cells dominate the thin-film solar market with lower manufacturing costs and a strong presence in large-scale utility projects, particularly driven by companies like First Solar. Market adoption of CdTe has been more widespread globally due to its mature technology and cost advantages, while CIGS continues expanding through innovation and specialized deployment.

Future Prospects and Developments

CIGS solar cells offer promising future prospects due to their flexibility, higher efficiency potential above 23%, and lower toxicity compared to CdTe cells, which face supply constraints due to limited tellurium availability. Advances in CIGS nanostructuring and tandem cell integration aim to boost performance and reduce manufacturing costs, making them suitable for diverse applications including building-integrated photovoltaics. Your choice might favor CIGS technology for sustainable growth and scalability as research continues to overcome stability and large-scale production challenges.

CIGS vs CdTe solar cell Infographic

electrown.com

electrown.com