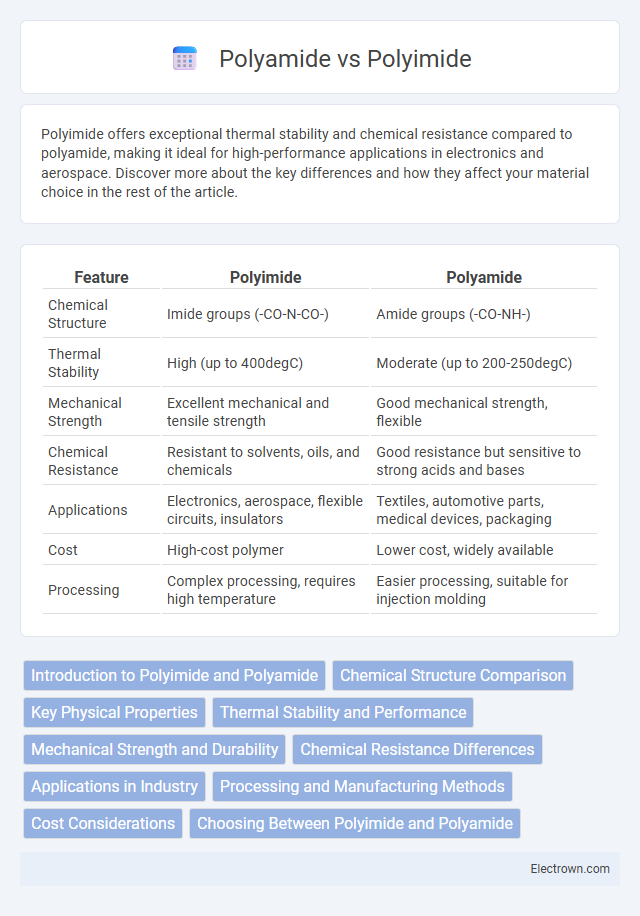

Polyimide offers exceptional thermal stability and chemical resistance compared to polyamide, making it ideal for high-performance applications in electronics and aerospace. Discover more about the key differences and how they affect your material choice in the rest of the article.

Table of Comparison

| Feature | Polyimide | Polyamide |

|---|---|---|

| Chemical Structure | Imide groups (-CO-N-CO-) | Amide groups (-CO-NH-) |

| Thermal Stability | High (up to 400degC) | Moderate (up to 200-250degC) |

| Mechanical Strength | Excellent mechanical and tensile strength | Good mechanical strength, flexible |

| Chemical Resistance | Resistant to solvents, oils, and chemicals | Good resistance but sensitive to strong acids and bases |

| Applications | Electronics, aerospace, flexible circuits, insulators | Textiles, automotive parts, medical devices, packaging |

| Cost | High-cost polymer | Lower cost, widely available |

| Processing | Complex processing, requires high temperature | Easier processing, suitable for injection molding |

Introduction to Polyimide and Polyamide

Polyimide and polyamide are high-performance polymers used in various industries for their distinct properties. Polyimide offers exceptional thermal stability, chemical resistance, and mechanical strength, making it ideal for electronics and aerospace applications. Polyamide, commonly known as nylon, provides excellent toughness, abrasion resistance, and flexibility, widely used in textiles, automotive parts, and industrial components; your choice depends on the specific thermal and mechanical requirements of your application.

Chemical Structure Comparison

Polyimides feature aromatic rings connected by imide linkages (-CO-N-CO-), offering exceptional thermal stability and chemical resistance, whereas polyamides (nylons) consist of amide bonds (-CONH-) linking aliphatic or aromatic chains, providing high mechanical strength and flexibility. The rigid, planar imide groups in polyimides result in higher glass transition temperatures compared to the more flexible polyamide backbone. Polyimides' chemical structure enables superior performance in extreme environments, while polyamides are more commonly used for their versatility and ease of processing.

Key Physical Properties

Polyimides exhibit superior thermal stability with glass transition temperatures typically above 300degC, whereas polyamides generally have lower thermal resistance, ranging between 40degC to 250degC. Polyimides possess excellent mechanical strength and dimensional stability under high-temperature conditions, while polyamides offer good toughness and abrasion resistance but may absorb more moisture, affecting their mechanical properties. The intrinsic rigidity of polyimide's aromatic backbone contrasts with the semi-crystalline structure of polyamides, influencing their flexibility and chemical resistance profiles.

Thermal Stability and Performance

Polyimide exhibits superior thermal stability compared to polyamide, maintaining structural integrity at temperatures above 300degC, making it ideal for high-temperature applications such as aerospace and electronics. In contrast, polyamide typically withstands continuous use temperatures up to 150-200degC but degrades faster under thermal stress. The enhanced thermal performance of polyimide stems from its aromatic imide groups, which provide greater resistance to heat and oxidation than the amide groups in polyamide.

Mechanical Strength and Durability

Polyimide exhibits superior mechanical strength and exceptional durability compared to polyamide, making it ideal for high-performance engineering applications. Its resistance to thermal degradation and chemical exposure enhances longevity under extreme conditions, while polyamide offers good flexibility but lower tensile strength and abrasion resistance. Your choice between these polymers should consider the demanding environment and mechanical stress your application will face.

Chemical Resistance Differences

Polyimide exhibits superior chemical resistance compared to polyamide, particularly against solvents, acids, and bases due to its aromatic imide rings and highly stable polymer backbone. Polyamide, while offering good resistance to oils and greases, is more susceptible to hydrolysis and degradation in acidic or alkaline environments. This chemical durability makes polyimide the preferred choice for applications requiring long-term exposure to aggressive chemicals and high-temperature solvents.

Applications in Industry

Polyimide and polyamide are both high-performance polymers with distinct industrial applications due to their unique properties. Polyimide is widely used in electronics and aerospace industries for its exceptional thermal stability, dielectric strength, and chemical resistance, making it ideal for flexible printed circuit boards, insulating films, and high-temperature components. Your choice between polyimide and polyamide depends on the specific application requirements, as polyamide excels in automotive and textile sectors for its toughness, abrasion resistance, and ease of processing.

Processing and Manufacturing Methods

Polyimide processing involves high-temperature curing and solvent-resistant film formation, typically requiring precision techniques such as spin coating, extrusion, and molding under controlled environments to maintain thermal stability and dimensional accuracy. Polyamide manufacturing utilizes melt processing methods including injection molding, extrusion, and blow molding, benefiting from its relatively lower melting point and good flow properties, enabling mass production of fibers, films, and molded parts. Both polymers demand specialized equipment, but polyimides require more stringent thermal management due to their superior thermal performance and chemical resistance, influencing tooling and cycle times.

Cost Considerations

Polyimide generally incurs higher manufacturing costs due to its complex chemical structure and specialized processing requirements compared to polyamide. Polyamide offers a more cost-effective solution with widespread availability and simpler production methods, making it suitable for applications with budget constraints. Your choice between these materials should weigh the performance benefits of polyimide against the economic advantages of polyamide.

Choosing Between Polyimide and Polyamide

Choosing between polyimide and polyamide depends on your application's temperature tolerance and chemical resistance requirements. Polyimides offer superior heat resistance up to 400degC and exceptional electrical insulation, making them ideal for aerospace and electronics. Polyamides, such as nylon, provide excellent mechanical strength and moisture resistance but have lower thermal stability, suitable for automotive and textiles.

polyimide vs polyamide Infographic

electrown.com

electrown.com