Hot air leveling creates a smooth, flat surface by applying molten solder followed by hot air to remove excess, ensuring excellent surface planarity for PCB manufacturing. Exploring the differences between hot air leveling and electroless nickel plating will help you determine the best finish for your electronic components--read on to learn more.

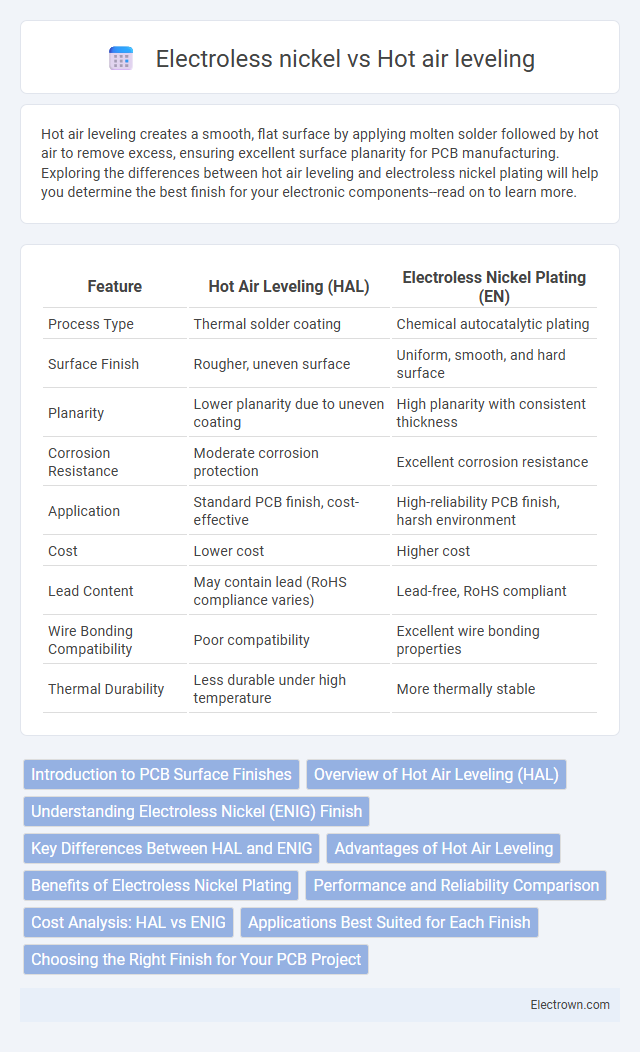

Table of Comparison

| Feature | Hot Air Leveling (HAL) | Electroless Nickel Plating (EN) |

|---|---|---|

| Process Type | Thermal solder coating | Chemical autocatalytic plating |

| Surface Finish | Rougher, uneven surface | Uniform, smooth, and hard surface |

| Planarity | Lower planarity due to uneven coating | High planarity with consistent thickness |

| Corrosion Resistance | Moderate corrosion protection | Excellent corrosion resistance |

| Application | Standard PCB finish, cost-effective | High-reliability PCB finish, harsh environment |

| Cost | Lower cost | Higher cost |

| Lead Content | May contain lead (RoHS compliance varies) | Lead-free, RoHS compliant |

| Wire Bonding Compatibility | Poor compatibility | Excellent wire bonding properties |

| Thermal Durability | Less durable under high temperature | More thermally stable |

Introduction to PCB Surface Finishes

Hot air leveling (HAL) and electroless nickel immersion gold (ENIG) are widely used PCB surface finishes that protect copper pads and ensure reliable solderability. HAL involves coating the PCB with molten solder and then removing excess solder with hot air knives, providing a cost-effective and solderable surface ideal for through-hole components. ENIG offers a thin layer of immersion gold over electroless nickel, delivering excellent flatness, corrosion resistance, and suitability for fine-pitch components, making it a preferred choice for advanced electronic applications.

Overview of Hot Air Leveling (HAL)

Hot Air Leveling (HAL) is a soldering finish used in printed circuit board (PCB) manufacturing that involves coating copper pads with molten solder followed by hot air knives to remove excess solder, creating a smooth and even surface. This process provides excellent wetting and solderability while offering good protection against oxidation. HAL is widely favored for its cost-effectiveness and ability to accommodate through-hole and surface-mount components, making it suitable for various PCB assembly applications.

Understanding Electroless Nickel (ENIG) Finish

Electroless Nickel (ENIG) finish provides a uniform coating of nickel and gold on PCB surfaces, enhancing corrosion resistance and electrical conductivity compared to hot air leveling. Unlike Hot Air Solder Leveling (HASL), ENIG offers superior surface planarity and is suitable for fine-pitch components due to its thin, even nickel-phosphorus layer topped with a thin gold layer. This finish supports complex circuit designs with improved solderability, making it a preferred choice for high-reliability electronics and advanced manufacturing processes.

Key Differences Between HAL and ENIG

Hot air leveling (HAL) involves coating copper surfaces with solder and then removing excess solder using hot air knives, resulting in a uniform solderable finish ideal for through-hole components. Electroless nickel immersion gold (ENIG) deposits a thin layer of nickel followed by a gold layer, providing superior corrosion resistance and a flat, reliable surface for surface-mount technology (SMT). Your choice between HAL and ENIG impacts solderability, surface planarity, and long-term durability of printed circuit boards (PCBs) used in different electronic applications.

Advantages of Hot Air Leveling

Hot air leveling offers superior surface planarity and excellent solderability by creating a flat, uniform finish that enhances component mounting reliability. This method provides cost-effective protection against oxidation and corrosion, extending PCB lifespan without requiring complex chemical treatments. Ideal for lead-free and high-frequency applications, hot air leveling ensures consistent coating thickness and improved thermal resistance compared to electroless nickel.

Benefits of Electroless Nickel Plating

Electroless nickel plating provides uniform coating thickness on complex geometries, enhancing corrosion resistance and wear protection compared to hot air leveling. This process eliminates the need for electrical current, enabling consistent deposition on all surfaces, including blind holes and recesses. Its superior hardness and excellent solderability improve the durability and performance of electronic components in harsh environments.

Performance and Reliability Comparison

Hot air leveling (HAL) provides a robust protective coating for printed circuit boards (PCBs), ensuring excellent solderability and good mechanical strength by forming a uniform, oxidation-resistant layer of solder. Electroless nickel immersion gold (ENIG) offers superior corrosion resistance and a flat, smooth surface that enhances the reliability of fine-pitch components and provides consistent electrical performance. ENIG generally outperforms HAL in long-term reliability due to its resistance to oxidation and superior shelf life, making it preferable for high-density, high-reliability applications.

Cost Analysis: HAL vs ENIG

Hot Air Leveling (HAL) generally offers lower initial manufacturing costs compared to Electroless Nickel Immersion Gold (ENIG) due to simpler processing and reduced material expenses, making it cost-effective for high-volume production. ENIG, while more expensive upfront because of its complex chemical deposition and precious metal usage, provides superior surface planarity and solderability, often reducing rework and enhancing long-term reliability. The total cost of ownership for HAL versus ENIG depends on specific application needs, including board complexity, production volume, and performance requirements, where ENIG may justify higher costs through improved yield and lifespan.

Applications Best Suited for Each Finish

Hot air leveling (HAL) is best suited for applications requiring solderable copper surfaces on printed circuit boards (PCBs), especially in through-hole technology and cost-sensitive mass production. Electroless nickel finishes excel in environments demanding superior corrosion resistance, wear protection, and consistent solderability, making them ideal for high-reliability electronics, including aerospace, medical devices, and automotive circuits. HAL is favored for general PCB assembly, while electroless nickel is preferred for complex multilayer boards and harsh operational conditions.

Choosing the Right Finish for Your PCB Project

Hot air leveling (HAL) provides a cost-effective, solderable surface ideal for standard PCB assemblies, offering good shelf life and easy reworkability. Electroless nickel immersion gold (ENIG) delivers superior surface planarity, excellent corrosion resistance, and longer storage stability, making it ideal for high-reliability and fine-pitch components. Selecting the right finish depends on factors such as project budget, component density, environmental exposure, and the required PCB lifespan.

Hot air leveling vs Electroless nickel Infographic

electrown.com

electrown.com