DBC substrates offer superior thermal conductivity and electrical insulation due to their copper base and ceramic layer, making them ideal for high-power electronic applications. Explore the rest of the article to understand how DPC substrates compare and which one suits Your specific needs.

Table of Comparison

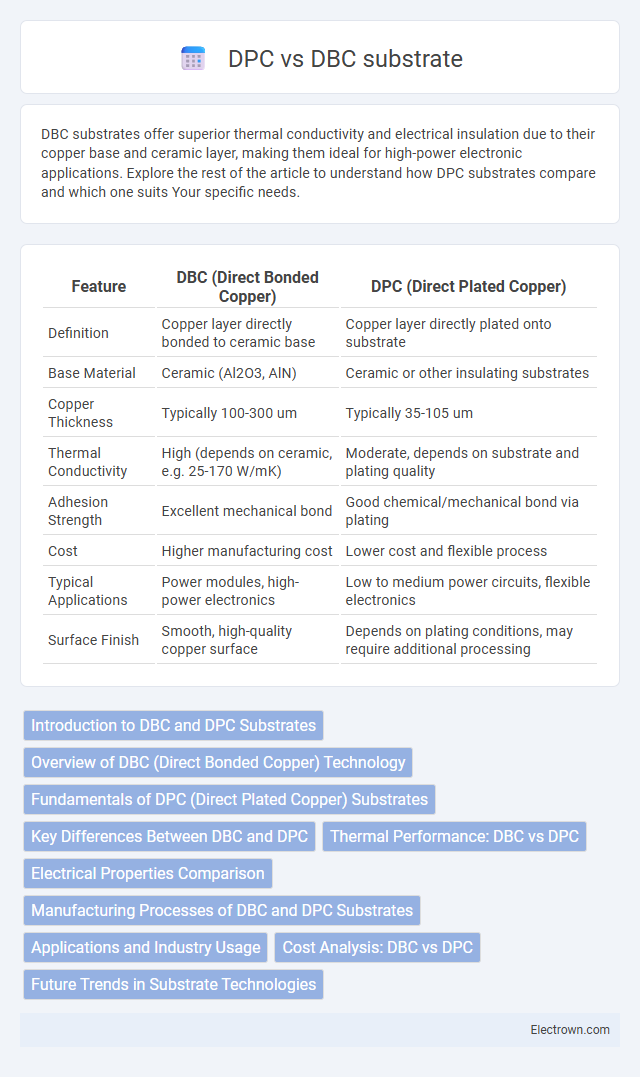

| Feature | DBC (Direct Bonded Copper) | DPC (Direct Plated Copper) |

|---|---|---|

| Definition | Copper layer directly bonded to ceramic base | Copper layer directly plated onto substrate |

| Base Material | Ceramic (Al2O3, AlN) | Ceramic or other insulating substrates |

| Copper Thickness | Typically 100-300 um | Typically 35-105 um |

| Thermal Conductivity | High (depends on ceramic, e.g. 25-170 W/mK) | Moderate, depends on substrate and plating quality |

| Adhesion Strength | Excellent mechanical bond | Good chemical/mechanical bond via plating |

| Cost | Higher manufacturing cost | Lower cost and flexible process |

| Typical Applications | Power modules, high-power electronics | Low to medium power circuits, flexible electronics |

| Surface Finish | Smooth, high-quality copper surface | Depends on plating conditions, may require additional processing |

Introduction to DBC and DPC Substrates

DBC (Direct Bonded Copper) substrates feature a ceramic core with copper bonded directly onto both sides, offering excellent thermal conductivity and mechanical strength for power electronics. DPC (Direct Plated Copper) substrates consist of a metal base with a plated copper layer, providing enhanced electrical performance and cost-efficiency in certain applications. Both substrates serve crucial roles in high-power density devices, balancing heat dissipation and electrical connectivity requirements.

Overview of DBC (Direct Bonded Copper) Technology

DBC (Direct Bonded Copper) technology involves bonding a layer of copper directly onto a ceramic substrate, such as alumina or aluminum nitride, providing excellent thermal conductivity and electrical insulation. This method ensures superior heat dissipation and mechanical stability in power electronics, making it ideal for high-power semiconductor devices and modules. Your applications benefit from DBC substrates' enhanced reliability and efficiency in managing heat compared to traditional printed circuit boards or DPC substrates.

Fundamentals of DPC (Direct Plated Copper) Substrates

DPC (Direct Plated Copper) substrates utilize a process where copper is directly electroplated onto an insulating base, allowing for superior heat dissipation and electrical conductivity compared to traditional DBC (Direct Bonded Copper) substrates. The key advantage of DPC lies in its cost efficiency and flexibility in manufacturing, enabling thinner copper layers and improved thermal management in power electronics. By choosing DPC substrates, your devices benefit from enhanced performance and reliability in applications demanding compact, high-power density solutions.

Key Differences Between DBC and DPC

DBC (Direct Bonded Copper) substrates feature a ceramic base with copper directly bonded to it, offering excellent thermal conductivity and enhanced mechanical strength ideal for high-power applications. DPC (Direct Plated Copper) substrates utilize a metal or composite base with a plated copper layer, providing superior electrical conductivity and flexibility in design but generally lower thermal performance compared to DBC. The key differences lie in thermal management, mechanical durability, and electrical characteristics, where DBC excels in heat dissipation and robustness, and DPC favors electrical efficiency and adaptability.

Thermal Performance: DBC vs DPC

DBC substrates offer superior thermal performance compared to DPC substrates due to their direct copper bonding to a ceramic base, enhancing heat dissipation efficiency. The ceramic layer in DBC substrates, often made from aluminum oxide or aluminum nitride, provides high thermal conductivity that effectively manages device temperatures. Choosing DBC substrates can significantly improve the thermal management of power electronics, protecting your components from overheating.

Electrical Properties Comparison

DBC (Direct Bonded Copper) substrates offer superior electrical conductivity due to their direct copper-to-ceramic bonding, resulting in lower electrical resistance and enhanced current carrying capacity compared to DPC (Direct Plated Copper) substrates. DBC substrates exhibit excellent dielectric strength and thermal conductivity, minimizing electrical losses and improving overall device efficiency. When selecting your substrate, DBC provides a more reliable electrical performance for high-power applications demanding efficient heat dissipation and stable conductivity.

Manufacturing Processes of DBC and DPC Substrates

DBC (Direct Bonded Copper) substrates are manufactured by bonding a copper foil directly to a ceramic base such as aluminum oxide or aluminum nitride through a high-temperature process that enables atomic diffusion and strong adhesion. DPC (Direct Plated Copper) substrates, on the other hand, use a chemical plating process to deposit copper onto the ceramic surface, often involving surface activation and electroplating to achieve a thin and uniform copper layer. The DBC process provides higher thermal conductivity and mechanical stability due to the metallurgical bond, whereas the DPC process allows for finer copper patterning and is generally more adaptable to complex circuit designs.

Applications and Industry Usage

DBC (Direct Bonded Copper) substrates are widely utilized in power electronics, automotive, and LED lighting industries due to their excellent thermal conductivity and robust mechanical properties. DPC (Direct Plated Copper) substrates find applications in telecommunications, high-frequency circuits, and advanced semiconductor packaging where fine circuit patterns and lower production costs are critical. Your choice between DBC and DPC substrates depends on the specific industry requirements, such as thermal management, electrical performance, and manufacturing complexity.

Cost Analysis: DBC vs DPC

DBC (Direct Bonded Copper) substrates generally incur higher manufacturing costs due to the complex bonding process and use of thick copper layers, which enhance thermal conductivity and reliability. In contrast, DPC (Direct Plated Copper) substrates offer cost advantages by utilizing a plated copper layer, reducing material usage and simplifying fabrication without significantly compromising electrical performance. The cost efficiency of DPC makes it suitable for applications requiring moderate thermal management, while DBC remains preferred for high-power and high-reliability demands despite its premium price.

Future Trends in Substrate Technologies

DBC (Direct Bonded Copper) and DPC (Direct Plated Copper) substrates are evolving to meet increasing demands for higher thermal management and electrical performance in power electronics. Future trends emphasize enhanced material composites and innovative bonding techniques to improve heat dissipation and mechanical reliability, critical for electric vehicles and renewable energy systems. You can expect advancements in nano-engineered interfaces and flexible substrates to further optimize performance and reduce manufacturing costs.

DBC vs DPC substrate Infographic

electrown.com

electrown.com