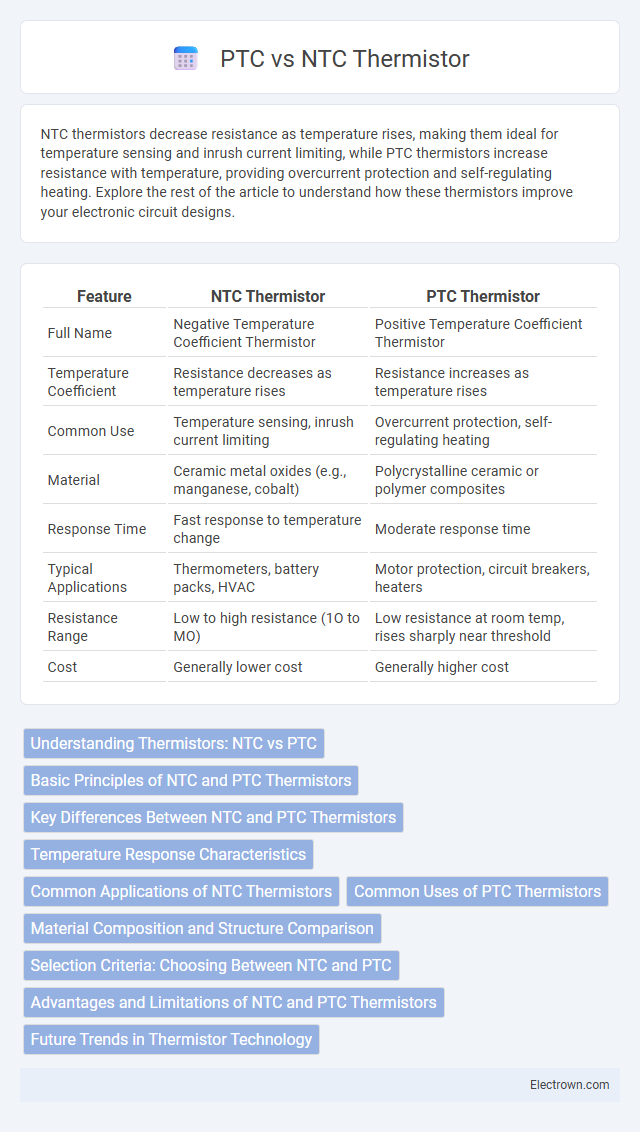

NTC thermistors decrease resistance as temperature rises, making them ideal for temperature sensing and inrush current limiting, while PTC thermistors increase resistance with temperature, providing overcurrent protection and self-regulating heating. Explore the rest of the article to understand how these thermistors improve your electronic circuit designs.

Table of Comparison

| Feature | NTC Thermistor | PTC Thermistor |

|---|---|---|

| Full Name | Negative Temperature Coefficient Thermistor | Positive Temperature Coefficient Thermistor |

| Temperature Coefficient | Resistance decreases as temperature rises | Resistance increases as temperature rises |

| Common Use | Temperature sensing, inrush current limiting | Overcurrent protection, self-regulating heating |

| Material | Ceramic metal oxides (e.g., manganese, cobalt) | Polycrystalline ceramic or polymer composites |

| Response Time | Fast response to temperature change | Moderate response time |

| Typical Applications | Thermometers, battery packs, HVAC | Motor protection, circuit breakers, heaters |

| Resistance Range | Low to high resistance (1O to MO) | Low resistance at room temp, rises sharply near threshold |

| Cost | Generally lower cost | Generally higher cost |

Understanding Thermistors: NTC vs PTC

NTC thermistors decrease resistance as temperature rises, making them ideal for precise temperature sensing and inrush current limiting, while PTC thermistors increase resistance with temperature, commonly used for overcurrent protection and self-regulating heating elements. Understanding the opposite resistance-temperature behaviors of NTC and PTC thermistors allows you to select the right type for applications requiring either accurate temperature measurement or circuit protection. Your choice hinges on whether responsive temperature detection or automatic circuit interruption best suits your device's operational needs.

Basic Principles of NTC and PTC Thermistors

NTC thermistors decrease their resistance as temperature rises, making them ideal for temperature sensing and inrush current limiting applications. PTC thermistors increase their resistance with temperature, providing self-regulating heating and overcurrent protection functions. The fundamental difference lies in their temperature-resistance relationship: NTC exhibits a negative temperature coefficient, while PTC exhibits a positive temperature coefficient.

Key Differences Between NTC and PTC Thermistors

NTC thermistors exhibit a decrease in resistance as temperature rises, making them ideal for precise temperature sensing and inrush current limiting. PTC thermistors increase resistance with higher temperatures, commonly used for overcurrent protection and self-regulating heating elements. The key difference lies in their opposite resistance-temperature characteristics, defining their distinct applications in electronic circuits and temperature control systems.

Temperature Response Characteristics

NTC thermistors exhibit a negative temperature coefficient, meaning their resistance decreases as temperature rises, enabling precise temperature measurements in cooling applications. In contrast, PTC thermistors have a positive temperature coefficient, where resistance increases with temperature, making them ideal for overcurrent protection and self-regulating heating systems. Understanding these temperature response characteristics helps you select the right thermistor for accurate thermal management and safety.

Common Applications of NTC Thermistors

NTC thermistors are widely used in temperature sensing applications such as digital thermostats, automotive temperature monitoring, and consumer electronics for accurate temperature measurement and control. Their high sensitivity to temperature changes enables effective use in circuit protection by preventing overheating and inrush current limiting in power supplies. NTC thermistors also play a crucial role in medical devices for patient temperature monitoring and HVAC systems for climate control optimization.

Common Uses of PTC Thermistors

PTC thermistors are commonly used as self-regulating heating elements in applications such as automotive cabin heaters, degaussing coils in CRT monitors, and overcurrent protection devices like resettable fuses. Their positive temperature coefficient property enables these thermistors to increase resistance as temperature rises, effectively limiting current flow and preventing overheating. This makes PTC thermistors essential components in circuits requiring reliable thermal management and safety.

Material Composition and Structure Comparison

NTC thermistors are typically made from metal oxides such as manganese, nickel, cobalt, and copper, which are sintered to form a ceramic structure with a negative temperature coefficient, causing resistance to decrease as temperature rises. PTC thermistors, often composed of polycrystalline ceramic materials like barium titanate, exhibit a positive temperature coefficient, where resistance sharply increases beyond a certain temperature threshold due to their unique grain boundary structure. Understanding the material composition and microstructure differences in your application helps optimize temperature sensing and protection performance.

Selection Criteria: Choosing Between NTC and PTC

Selecting between NTC and PTC thermistors depends on your application's temperature sensing and circuit protection needs. NTC thermistors offer precise temperature measurement with resistance decreasing as temperature rises, ideal for temperature monitoring and compensation. PTC thermistors increase resistance with temperature, providing effective overcurrent protection and self-regulating heating functions in your system.

Advantages and Limitations of NTC and PTC Thermistors

NTC thermistors provide high sensitivity and fast response for temperature measurement, excelling in precise temperature control and inrush current limiting, but they can be less stable under high temperatures and have a narrower operating range. PTC thermistors offer self-regulating protection with a sharp resistance increase at a specific temperature, making them ideal for overcurrent protection and self-resetting fuses, yet they generally have slower response times and less accuracy in temperature sensing compared to NTC types. Understanding Your application's temperature range and required response characteristics helps determine whether an NTC or PTC thermistor is best suited for performance and reliability.

Future Trends in Thermistor Technology

NTC and PTC thermistor technology is evolving with advancements in nanomaterials and smart sensor integration, enhancing accuracy and response time. Emerging trends include the development of flexible thermistors for wearable devices and IoT applications, enabling real-time temperature monitoring with improved energy efficiency. Your utilization of these cutting-edge thermistors will benefit from improved durability and compatibility with AI-driven predictive maintenance systems.

NTC vs PTC thermistor Infographic

electrown.com

electrown.com