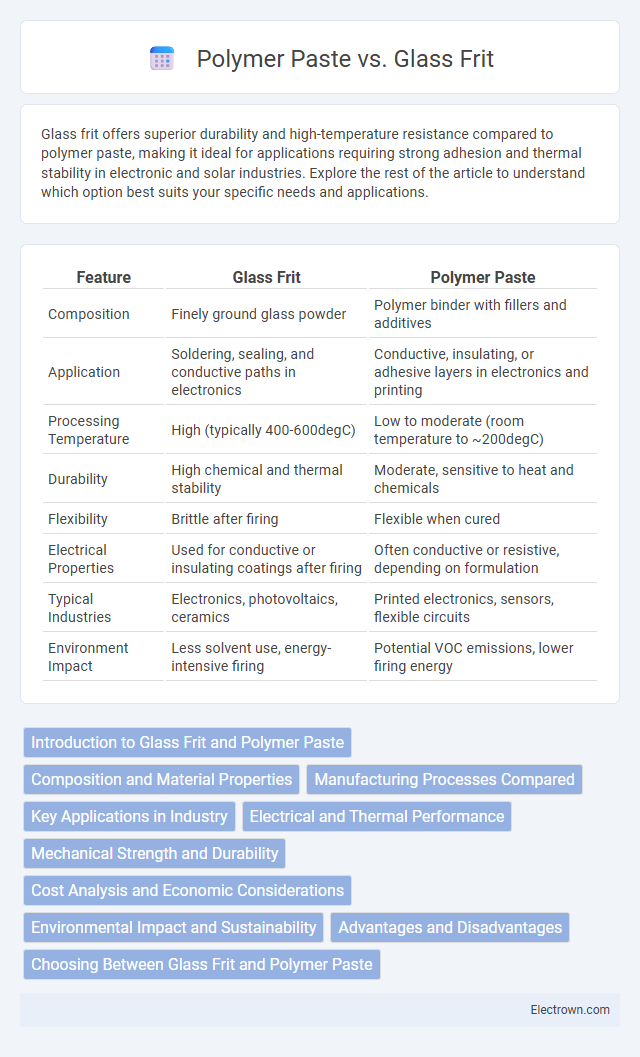

Glass frit offers superior durability and high-temperature resistance compared to polymer paste, making it ideal for applications requiring strong adhesion and thermal stability in electronic and solar industries. Explore the rest of the article to understand which option best suits your specific needs and applications.

Table of Comparison

| Feature | Glass Frit | Polymer Paste |

|---|---|---|

| Composition | Finely ground glass powder | Polymer binder with fillers and additives |

| Application | Soldering, sealing, and conductive paths in electronics | Conductive, insulating, or adhesive layers in electronics and printing |

| Processing Temperature | High (typically 400-600degC) | Low to moderate (room temperature to ~200degC) |

| Durability | High chemical and thermal stability | Moderate, sensitive to heat and chemicals |

| Flexibility | Brittle after firing | Flexible when cured |

| Electrical Properties | Used for conductive or insulating coatings after firing | Often conductive or resistive, depending on formulation |

| Typical Industries | Electronics, photovoltaics, ceramics | Printed electronics, sensors, flexible circuits |

| Environment Impact | Less solvent use, energy-intensive firing | Potential VOC emissions, lower firing energy |

Introduction to Glass Frit and Polymer Paste

Glass frit is a finely ground glass powder used in various bonding and sealing applications, especially in electronics and solar panel manufacturing, due to its excellent thermal stability and electrical insulation properties. Polymer paste consists of polymer-based compounds mixed with fillers and solvents, offering flexibility, easy application, and strong adhesion for electronic packaging and printed circuit boards. Both materials serve critical roles in microelectronics, with glass frit preferred for high-temperature durability and polymer paste valued for process versatility and mechanical resilience.

Composition and Material Properties

Glass frit consists primarily of finely ground glass particles combined with inorganic additives, offering high thermal stability, chemical resistance, and excellent bonding with ceramic or glass substrates. Polymer paste, made of organic polymers mixed with fillers like silica or carbon black, provides flexibility, lower curing temperatures, and better adhesion on diverse surfaces but has reduced thermal and chemical durability compared to glass frit. The inorganic nature of glass frit ensures superior performance in high-temperature applications, whereas polymer paste is optimized for processes requiring lower thermal budgets and mechanical flexibility.

Manufacturing Processes Compared

Glass frit and polymer paste differ significantly in manufacturing processes, with glass frit typically produced through controlled melting and quenching of raw materials, followed by grinding to achieve fine particle sizes essential for applications like solar cell metallization. Polymer paste manufacturing involves the careful mixing of conductive particles, such as silver or copper, with polymer binders and solvents under precise conditions to ensure uniform consistency and optimal adhesion properties. The thermal treatment differs as glass frit requires high-temperature firing to sinter particles, while polymer pastes often cure at lower temperatures, influencing the choice of substrates and overall production cost efficiency.

Key Applications in Industry

Glass frit is extensively used in the electronics and solar industries for sealing, bonding, and as an insulating material in components like OLED displays and photovoltaic modules. Polymer paste finds key applications in printed electronics, flexible circuits, and sensor manufacturing due to its excellent adhesion and flexibility properties. Your choice between glass frit and polymer paste depends on the specific requirements for thermal stability, mechanical strength, and electrical insulation in your industrial application.

Electrical and Thermal Performance

Glass frit offers superior electrical insulation and thermal stability, making it ideal for high-temperature applications such as semiconductor packaging and photovoltaic modules. Polymer paste, while more flexible and easier to process, typically exhibits lower thermal conductivity and diminished electrical resistance under prolonged heat exposure. The choice between glass frit and polymer paste directly impacts device reliability and efficiency in electrically demanding and thermally stressful environments.

Mechanical Strength and Durability

Glass frit offers superior mechanical strength and long-lasting durability due to its rigid, inorganic composition, making it ideal for high-temperature and harsh environmental applications. Polymer paste, while more flexible and easier to process, generally exhibits lower mechanical stability and can degrade over time under thermal or chemical stress. Your choice between these materials should depend on the specific mechanical demands and environmental conditions of your project.

Cost Analysis and Economic Considerations

Glass frit typically offers a lower cost per unit volume compared to polymer paste due to its widespread availability and simpler manufacturing process. Polymer paste, while potentially more expensive upfront, can reduce long-term expenses by enhancing adhesion and durability, leading to lower maintenance and replacement costs. Evaluating total cost of ownership involves balancing initial material costs with performance benefits and application-specific requirements.

Environmental Impact and Sustainability

Glass frit offers a more environmentally sustainable option compared to polymer paste due to its inorganic composition and recyclability, resulting in lower carbon emissions during manufacturing and disposal. Polymer paste typically involves synthetic organic compounds that can release volatile organic compounds (VOCs) and generate non-biodegradable waste, posing greater environmental challenges. Choosing glass frit for your applications supports eco-friendly practices by reducing hazardous waste and enhancing recyclability in electronic and photovoltaic industries.

Advantages and Disadvantages

Glass frit offers superior thermal stability and chemical resistance, making it ideal for high-temperature applications and long-term durability. Polymer paste provides easier processing with flexible application options and faster curing times but may suffer from lower mechanical strength and reduced thermal resistance. Choosing between glass frit and polymer paste depends on the specific requirements of thermal performance, mechanical durability, and manufacturing speed for the intended use.

Choosing Between Glass Frit and Polymer Paste

Choosing between glass frit and polymer paste depends on the specific application requirements such as temperature resistance, adhesion properties, and durability. Glass frit offers superior thermal stability and chemical resistance, making it ideal for high-temperature sealing and electronic packaging. Polymer paste provides better flexibility and ease of processing, suitable for applications requiring low-temperature curing and temporary bonding.

glass frit vs polymer paste Infographic

electrown.com

electrown.com