Polymer capacitors offer lower Equivalent Series Resistance (ESR) and improved stability over a wide temperature range compared to ceramic capacitors, which provide higher capacitance values and better performance at high frequencies but may suffer from microphonic effects. Discover how choosing between polymer and ceramic capacitors can impact Your electronic design by exploring the detailed comparison in the rest of the article.

Table of Comparison

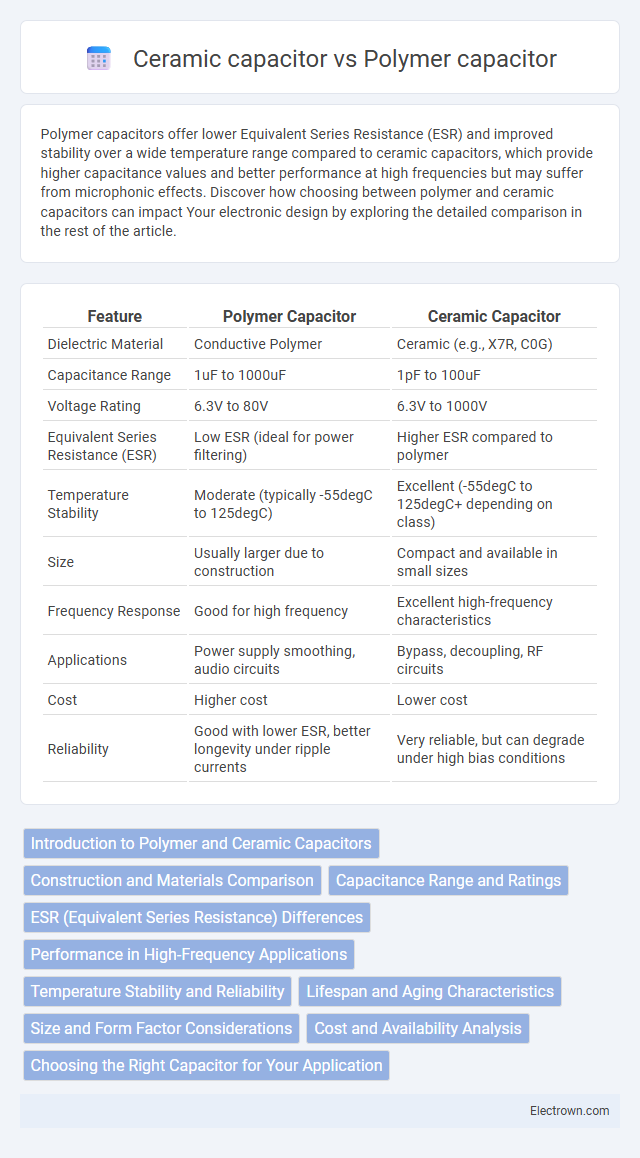

| Feature | Polymer Capacitor | Ceramic Capacitor |

|---|---|---|

| Dielectric Material | Conductive Polymer | Ceramic (e.g., X7R, C0G) |

| Capacitance Range | 1uF to 1000uF | 1pF to 100uF |

| Voltage Rating | 6.3V to 80V | 6.3V to 1000V |

| Equivalent Series Resistance (ESR) | Low ESR (ideal for power filtering) | Higher ESR compared to polymer |

| Temperature Stability | Moderate (typically -55degC to 125degC) | Excellent (-55degC to 125degC+ depending on class) |

| Size | Usually larger due to construction | Compact and available in small sizes |

| Frequency Response | Good for high frequency | Excellent high-frequency characteristics |

| Applications | Power supply smoothing, audio circuits | Bypass, decoupling, RF circuits |

| Cost | Higher cost | Lower cost |

| Reliability | Good with lower ESR, better longevity under ripple currents | Very reliable, but can degrade under high bias conditions |

Introduction to Polymer and Ceramic Capacitors

Polymer capacitors use conductive polymer as the electrolyte, offering low equivalent series resistance (ESR) and high ripple current capability, making them ideal for high-frequency and power applications. Ceramic capacitors, made from dielectric ceramic materials, provide excellent stability, low leakage current, and are commonly used in decoupling and filtering at high frequencies. The choice between polymer and ceramic capacitors depends on application requirements such as ESR, capacitance range, and thermal stability.

Construction and Materials Comparison

Polymer capacitors feature an aluminum electrolytic design with a conductive polymer as the electrolyte, providing lower equivalent series resistance (ESR) and enhanced thermal stability compared to traditional aluminum electrolytic capacitors. Ceramic capacitors are constructed using multiple layers of ceramic dielectric materials sandwiched between metal electrodes, offering high capacitance stability and excellent high-frequency performance. The polymer electrolytes in polymer capacitors improve durability and ripple current capability, while ceramic capacitors excel in miniaturization and voltage handling due to their dense ceramic construction.

Capacitance Range and Ratings

Polymer capacitors typically offer capacitance values ranging from 0.1 uF to several thousand microfarads, with voltage ratings up to about 100V or more, making them suitable for high capacitance and moderate voltage applications. Ceramic capacitors cover a broader voltage range, from a few volts up to several kilovolts, but their capacitance values generally span from a few picofarads to several microfarads, which suits them for high-frequency and lower capacitance needs. The choice between polymer and ceramic capacitors depends on the required capacitance stability, voltage rating, and application frequency.

ESR (Equivalent Series Resistance) Differences

Polymer capacitors exhibit significantly lower ESR compared to ceramic capacitors, enhancing performance in high-frequency and high ripple current applications. Their conductive polymer electrolyte reduces heat generation and power losses, making them ideal for power supply circuits requiring stable efficiency. Choosing polymer capacitors can improve your device's longevity and reliability where minimal ESR is critical.

Performance in High-Frequency Applications

Polymer capacitors exhibit lower equivalent series resistance (ESR) and superior stability at high frequencies compared to ceramic capacitors, making them ideal for applications requiring efficient noise filtering and power delivery. Ceramic capacitors generally offer excellent high-frequency characteristics due to their low inductance but can suffer from microphonic effects and capacitance loss under mechanical stress. Selecting polymer capacitors enhances durability and performance in power supply circuits and RF modules where consistent capacitance and minimal signal distortion are critical.

Temperature Stability and Reliability

Polymer capacitors offer superior temperature stability with a typical operating range from -55degC to +105degC, maintaining consistent capacitance and low Equivalent Series Resistance (ESR) over time. Ceramic capacitors, especially Class 2 types like X7R, exhibit more significant capacitance variation with temperature changes and may suffer from micro-cracking under thermal stress, impacting reliability. Your choice should consider polymer capacitors for demanding temperature environments requiring long-term stability, while ceramics are preferred for applications with less stringent thermal requirements.

Lifespan and Aging Characteristics

Polymer capacitors exhibit longer lifespan and superior aging characteristics compared to ceramic capacitors due to their stable conductive polymer electrolyte, which resists drying out and maintains capacitance over time. Ceramic capacitors, especially Class II and III types, experience significant capacitance degradation and increased equivalent series resistance (ESR) under thermal and electrical stress, leading to shorter effective lifetimes. The reliability of polymer capacitors in high-temperature and high-stress environments makes them ideal for applications requiring consistent performance and extended service intervals.

Size and Form Factor Considerations

Polymer capacitors generally offer a larger size compared to ceramic capacitors due to their construction involving conductive polymer electrodes, making them less suitable for ultra-compact designs. Ceramic capacitors excel in providing a smaller form factor and are preferred in applications with strict space constraints, such as mobile devices and high-density circuit boards. Your choice should consider space availability and performance requirements, as polymer capacitors provide higher capacitance values but ceramic capacitors are more versatile in miniaturized electronics.

Cost and Availability Analysis

Polymer capacitors generally have a higher cost compared to ceramic capacitors due to their advanced electrolyte materials and manufacturing processes. Ceramic capacitors are widely available and cost-effective, making them suitable for high-volume applications where budget constraints are critical. Your choice depends on balancing polymer capacitors' enhanced performance benefits against the affordability and abundance of ceramic capacitors.

Choosing the Right Capacitor for Your Application

Polymer capacitors offer low equivalent series resistance (ESR) and high ripple current capability, making them ideal for power supply filtering and high-frequency applications. Ceramic capacitors excel in high stability and low loss with capacitance values suitable for decoupling and high-frequency resonance circuits. Understanding your application's voltage, capacitance, and frequency requirements ensures selecting the optimal capacitor type for performance and reliability.

Polymer capacitor vs Ceramic capacitor Infographic

electrown.com

electrown.com