Undoped silicon, known for its pure crystalline structure, has limited electrical conductivity, while doped silicon contains impurities that significantly enhance its conductivity by introducing free charge carriers. Discover how these fundamental differences impact semiconductor performance and your electronic device applications in the rest of this article.

Table of Comparison

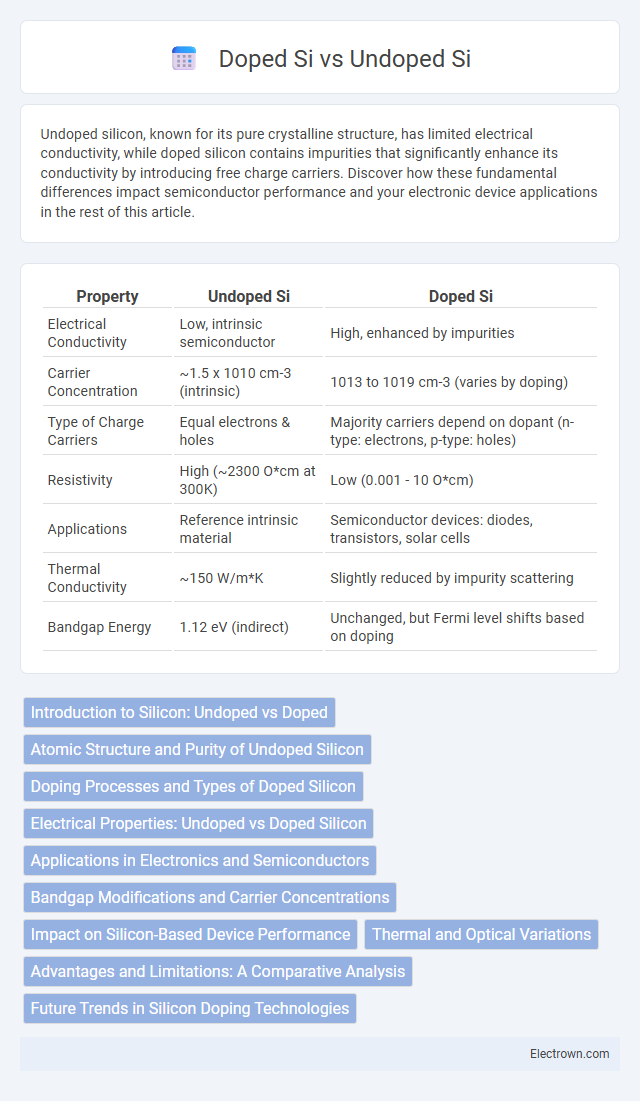

| Property | Undoped Si | Doped Si |

|---|---|---|

| Electrical Conductivity | Low, intrinsic semiconductor | High, enhanced by impurities |

| Carrier Concentration | ~1.5 x 1010 cm-3 (intrinsic) | 1013 to 1019 cm-3 (varies by doping) |

| Type of Charge Carriers | Equal electrons & holes | Majority carriers depend on dopant (n-type: electrons, p-type: holes) |

| Resistivity | High (~2300 O*cm at 300K) | Low (0.001 - 10 O*cm) |

| Applications | Reference intrinsic material | Semiconductor devices: diodes, transistors, solar cells |

| Thermal Conductivity | ~150 W/m*K | Slightly reduced by impurity scattering |

| Bandgap Energy | 1.12 eV (indirect) | Unchanged, but Fermi level shifts based on doping |

Introduction to Silicon: Undoped vs Doped

Undoped silicon consists of pure silicon atoms with no intentional impurities, resulting in limited electrical conductivity primarily due to intrinsic charge carriers. Doped silicon contains controlled amounts of impurities, such as phosphorus or boron, which introduce free electrons or holes to significantly enhance conductivity and tailor semiconductor properties. Understanding the differences between undoped and doped silicon is essential for optimizing your electronic device performance and fabrication processes.

Atomic Structure and Purity of Undoped Silicon

Undoped silicon consists of a pure crystalline atomic structure with a regular arrangement of silicon atoms, maintaining high purity levels that enable intrinsic semiconductor behavior. The absence of impurity atoms preserves the natural electrical properties, resulting in low electrical conductivity at room temperature. Your electronics and semiconductor devices rely on this fundamental purity to ensure predictable performance before intentional doping alters conductivity.

Doping Processes and Types of Doped Silicon

Doped silicon is created by introducing impurity atoms such as phosphorus, boron, or arsenic into undoped silicon through processes like ion implantation or diffusion to modify its electrical properties. N-type silicon is formed by adding pentavalent dopants, which provide extra electrons, while p-type silicon results from trivalent dopants that create holes as charge carriers. The controlled doping process adjusts silicon's conductivity and enables its use in semiconductor devices like transistors and diodes.

Electrical Properties: Undoped vs Doped Silicon

Undoped silicon exhibits high resistivity due to its intrinsic semiconductor nature with very few free charge carriers, resulting in limited electrical conductivity. Doped silicon incorporates impurities such as phosphorus (n-type) or boron (p-type) to drastically increase free electron or hole concentrations, enhancing conductivity by several orders of magnitude. This doping process precisely controls the material's electrical properties, enabling the creation of p-n junctions essential for semiconductor devices like diodes and transistors.

Applications in Electronics and Semiconductors

Undoped silicon (intrinsic Si) serves as the fundamental material in semiconductor devices, offering high purity and consistent electrical properties essential for initial wafer fabrication and insulating layers. Doped silicon, infused with controlled impurities like phosphorus or boron, significantly enhances conductivity and enables precise control of charge carriers, making it indispensable for creating p-n junctions in transistors, diodes, and integrated circuits. This doping process optimizes the electrical performance of electronic components, driving advancements in microprocessors, solar cells, and sensors.

Bandgap Modifications and Carrier Concentrations

Undoped Si has an intrinsic bandgap of approximately 1.12 eV at room temperature, resulting in low carrier concentrations primarily due to thermally generated electron-hole pairs. Introducing dopants like phosphorus or boron creates energy levels within the bandgap, effectively narrowing the bandgap for conduction and dramatically increasing carrier concentrations by adding free electrons or holes. Your semiconductor device performance depends heavily on these modifications, as doped Si enables higher conductivity and tailored electrical properties for specific applications.

Impact on Silicon-Based Device Performance

Undoped silicon (intrinsic Si) exhibits low electrical conductivity due to the limited number of free charge carriers, resulting in slower device operation and higher resistance. Doped silicon introduces controlled impurities, such as phosphorus or boron, significantly increasing carrier concentration and enhancing conductivity, which improves switching speeds and overall silicon-based device efficiency. The precise doping level and type directly influence device parameters like threshold voltage, leakage current, and power consumption, optimizing performance for applications in transistors, diodes, and integrated circuits.

Thermal and Optical Variations

Undoped silicon exhibits higher thermal conductivity and lower free carrier absorption compared to doped silicon, which experiences increased phonon scattering and free carrier absorption due to impurity atoms. The introduction of dopants in silicon causes a reduction in thermal conductivity by disrupting the crystal lattice, leading to enhanced non-radiative recombination and modified optical bandgap characteristics. Optical absorption spectra of doped silicon show distinct impurity levels within the bandgap, altering transmittance and reflectance properties compared to the intrinsic, undoped counterpart.

Advantages and Limitations: A Comparative Analysis

Undoped Si offers superior purity and intrinsic electrical properties ideal for high-precision applications but suffers from low conductivity, limiting its use in standard semiconductor devices. Doped Si significantly enhances electrical conductivity by introducing controlled impurities such as phosphorus or boron, enabling efficient charge carrier movement crucial for transistors and integrated circuits. Your choice between undoped and doped Si must balance the need for purity against the necessity for tailored electrical performance, considering application-specific requirements for speed, power consumption, and manufacturing complexity.

Future Trends in Silicon Doping Technologies

Emerging trends in silicon doping technologies emphasize atomic-level precision through advanced techniques such as ion implantation and plasma doping, enabling enhanced control over electrical properties in semiconductor devices. Research in ultra-shallow junctions and co-doping strategies aims to improve device performance by minimizing diffusion and enhancing carrier concentration uniformity. Moreover, novel doping approaches integrating two-dimensional materials and in-situ doping during epitaxial growth are poised to revolutionize silicon-based microelectronics for next-generation applications.

Undoped Si vs Doped Si Infographic

electrown.com

electrown.com