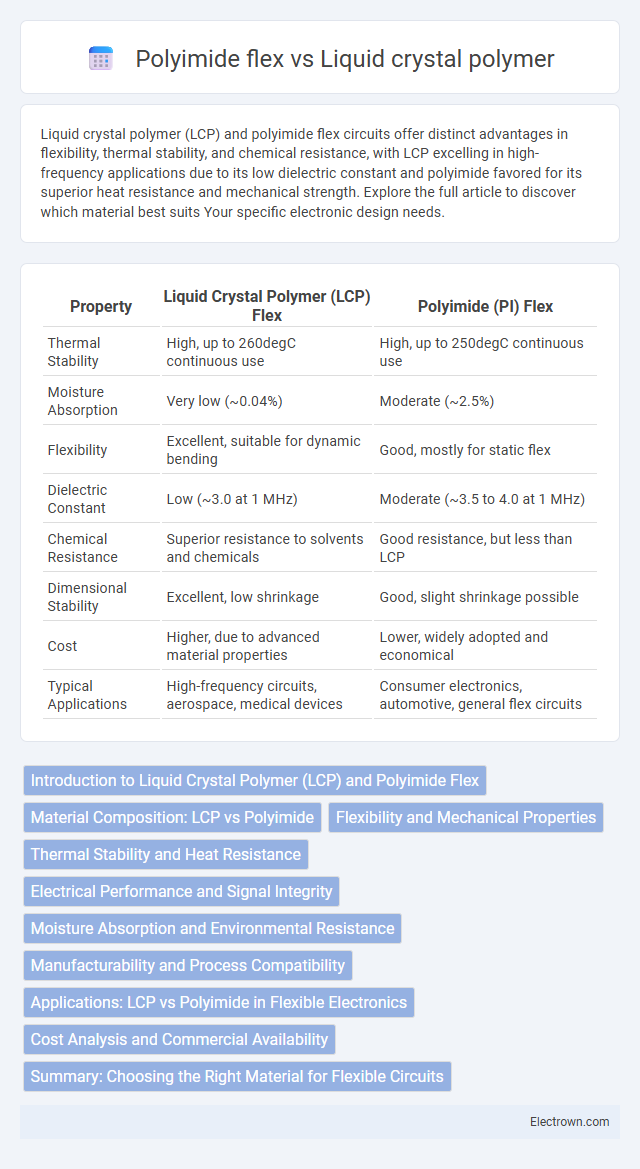

Liquid crystal polymer (LCP) and polyimide flex circuits offer distinct advantages in flexibility, thermal stability, and chemical resistance, with LCP excelling in high-frequency applications due to its low dielectric constant and polyimide favored for its superior heat resistance and mechanical strength. Explore the full article to discover which material best suits Your specific electronic design needs.

Table of Comparison

| Property | Liquid Crystal Polymer (LCP) Flex | Polyimide (PI) Flex |

|---|---|---|

| Thermal Stability | High, up to 260degC continuous use | High, up to 250degC continuous use |

| Moisture Absorption | Very low (~0.04%) | Moderate (~2.5%) |

| Flexibility | Excellent, suitable for dynamic bending | Good, mostly for static flex |

| Dielectric Constant | Low (~3.0 at 1 MHz) | Moderate (~3.5 to 4.0 at 1 MHz) |

| Chemical Resistance | Superior resistance to solvents and chemicals | Good resistance, but less than LCP |

| Dimensional Stability | Excellent, low shrinkage | Good, slight shrinkage possible |

| Cost | Higher, due to advanced material properties | Lower, widely adopted and economical |

| Typical Applications | High-frequency circuits, aerospace, medical devices | Consumer electronics, automotive, general flex circuits |

Introduction to Liquid Crystal Polymer (LCP) and Polyimide Flex

Liquid Crystal Polymer (LCP) and Polyimide Flex are advanced materials widely used in flexible electronics and circuit design, with LCP known for its excellent chemical resistance, low moisture absorption, and superior electrical properties. Polyimide Flex offers exceptional thermal stability, mechanical strength, and flexibility, making it ideal for high-density interconnects and robust circuit applications. Choosing between LCP and Polyimide Flex depends on your specific requirements for performance under harsh environmental conditions and the flexibility needed in your design.

Material Composition: LCP vs Polyimide

Liquid crystal polymer (LCP) is a highly ordered aromatic polyester known for its low moisture absorption, excellent chemical resistance, and superior dimensional stability, making it ideal for high-frequency and high-speed electronic applications. Polyimide, a polymer characterized by its imide linkages, offers outstanding thermal stability, mechanical strength, and flexibility, commonly used in flexible printed circuit boards and electronic insulation. The molecular structure of LCP provides higher rigidity and lower dielectric constant compared to the more amorphous and thermally robust polyimide, influencing their respective performances in flexible electronics.

Flexibility and Mechanical Properties

Liquid crystal polymer (LCP) offers superior dimensional stability and high mechanical strength, maintaining flexibility even under elevated temperatures, making it ideal for advanced flexible electronics. Polyimide flex circuits provide excellent flexibility with good dielectric properties but tend to be less resistant to mechanical stress over time compared to LCP. Your choice between LCP and Polyimide depends on the required balance between flexibility, thermal endurance, and long-term mechanical durability for your specific application.

Thermal Stability and Heat Resistance

Liquid crystal polymers (LCPs) exhibit superior thermal stability with a heat resistance often exceeding 300degC, making them ideal for high-temperature applications compared to polyimide flex circuits, which typically withstand temperatures around 200-250degC. LCPs maintain mechanical integrity and dimensional stability under prolonged heat exposure, while polyimide flex materials may experience more significant thermal expansion and degradation. Your choice between LCP and polyimide flex should consider the operating temperature range, as LCP provides enhanced performance in demanding thermal environments.

Electrical Performance and Signal Integrity

Liquid crystal polymer (LCP) offers superior electrical performance with lower dielectric constant and dissipation factor compared to polyimide flex, resulting in reduced signal attenuation and minimal signal distortion at high frequencies. The low moisture absorption and stable dielectric properties of LCP enhance signal integrity in demanding high-speed and high-frequency applications such as RF and microwave circuits. Polyimide flex, while flexible and thermally stable, exhibits higher dielectric losses and moisture sensitivity, which can compromise signal integrity in ultra-high-speed data transmission environments.

Moisture Absorption and Environmental Resistance

Liquid crystal polymer (LCP) exhibits significantly lower moisture absorption rates, typically less than 0.02%, compared to polyimide flex materials, which absorb around 2-3%, enhancing LCP's dimensional stability in humid environments. LCP also offers superior environmental resistance, including resistance to chemicals, UV radiation, and high temperatures up to 260degC, outperforming polyimide's maximum continuous use temperature of approximately 200degC. These properties make LCP ideal for flexible circuits in harsh or high-moisture conditions, while polyimide remains a reliable choice for moderately demanding applications.

Manufacturability and Process Compatibility

Liquid crystal polymer (LCP) flex circuits offer superior manufacturability due to their low moisture absorption and excellent chemical resistance, enabling reliable high-frequency performance and minimal signal distortion during fabrication. In contrast, polyimide flex circuits provide broader process compatibility with standard PCB manufacturing techniques, including soldering and surface mount assembly, due to their thermal stability and mechanical flexibility. Both materials accommodate diverse manufacturing processes, but LCP excels in applications requiring enhanced chemical durability and electrical performance, while polyimide is preferred for cost-effective, versatile production workflows.

Applications: LCP vs Polyimide in Flexible Electronics

Liquid crystal polymer (LCP) offers superior moisture resistance and high-frequency performance, making it ideal for RF and antenna applications in flexible electronics. Polyimide flex is valued for its thermal stability and mechanical flexibility, widely used in display technology and wearable devices. Your choice between LCP and polyimide depends on application demands such as signal integrity, environmental conditions, and mechanical endurance.

Cost Analysis and Commercial Availability

Liquid crystal polymer (LCP) offers higher material costs but provides superior chemical resistance and thermal stability compared to polyimide flex, which remains the more budget-friendly option suitable for most standard applications. Polyimide flex materials enjoy broader commercial availability and extensive supplier networks, making them easier to source for large-scale manufacturing. Your choice between LCP and polyimide flex should balance cost constraints with performance requirements and supply chain accessibility.

Summary: Choosing the Right Material for Flexible Circuits

Liquid crystal polymer (LCP) offers superior chemical resistance, low moisture absorption, and excellent dimensional stability, making it ideal for high-frequency, high-reliability flexible circuits. Polyimide flex circuits provide exceptional thermal stability, flexibility, and cost-effectiveness, commonly used in diverse electronics requiring moderate performance standards. Selecting between LCP and polyimide depends on application-specific requirements such as operating environment, mechanical stress, and electrical performance needs.

Liquid crystal polymer vs Polyimide flex Infographic

electrown.com

electrown.com