Sputtered targets and evaporation sources are two primary methods for thin film deposition; sputtered targets use plasma to eject atoms from a solid material onto a substrate, resulting in high-density, uniform coatings, while evaporation sources rely on heating materials until they vaporize and condense on the substrate, offering simpler equipment but less control over film properties. To understand which technique suits your application best, explore the detailed comparison in the rest of this article.

Table of Comparison

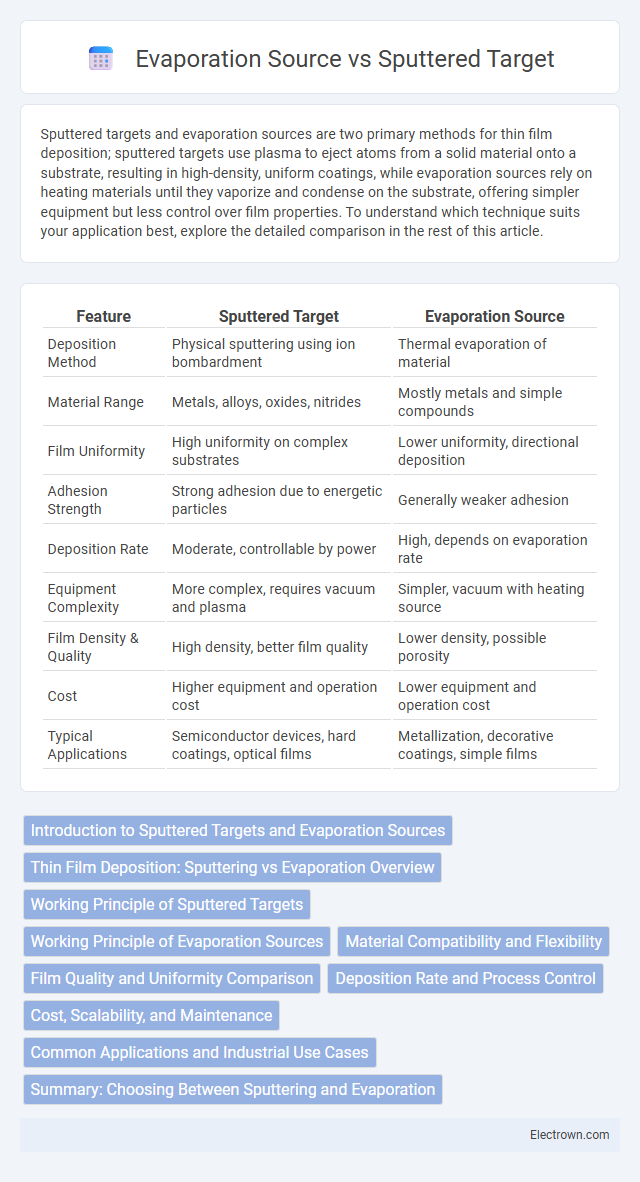

| Feature | Sputtered Target | Evaporation Source |

|---|---|---|

| Deposition Method | Physical sputtering using ion bombardment | Thermal evaporation of material |

| Material Range | Metals, alloys, oxides, nitrides | Mostly metals and simple compounds |

| Film Uniformity | High uniformity on complex substrates | Lower uniformity, directional deposition |

| Adhesion Strength | Strong adhesion due to energetic particles | Generally weaker adhesion |

| Deposition Rate | Moderate, controllable by power | High, depends on evaporation rate |

| Equipment Complexity | More complex, requires vacuum and plasma | Simpler, vacuum with heating source |

| Film Density & Quality | High density, better film quality | Lower density, possible porosity |

| Cost | Higher equipment and operation cost | Lower equipment and operation cost |

| Typical Applications | Semiconductor devices, hard coatings, optical films | Metallization, decorative coatings, simple films |

Introduction to Sputtered Targets and Evaporation Sources

Sputtered targets and evaporation sources are fundamental components in thin film deposition processes vital for electronics and coating industries. Sputtered targets involve bombarding a solid material with high-energy ions to eject atoms onto a substrate, offering superior film adhesion and uniformity. Evaporation sources, by heating materials until they vaporize, provide efficient deposition rates but may result in less conformal coatings compared to sputtering, influencing your choice depending on the application requirements.

Thin Film Deposition: Sputtering vs Evaporation Overview

Sputtered targets enable uniform thin film deposition by ejecting atoms through ionized gas bombardment, providing high adhesion and density compared to evaporation sources, which rely on thermal energy to vaporize materials. Sputtering offers better control over film composition and thickness, ideal for complex alloys and compound films, while evaporation excels in depositing metals with high purity and smooth surface morphology. In semiconductor and optics industries, sputtering is preferred for its ability to deposit conformal coatings on intricate substrates, whereas evaporation suits applications requiring high deposition rates and minimal equipment cost.

Working Principle of Sputtered Targets

Sputtered targets operate through the principle of physical vapor deposition, where ions from a plasma collide with the target material, ejecting atoms that then deposit onto a substrate. This process enables precise control over film thickness and composition, offering advantages in uniformity and adhesion compared to evaporation sources. Your choice of sputtered targets improves coating quality for applications demanding high durability and fine microstructure control.

Working Principle of Evaporation Sources

Evaporation sources operate by heating a material until it vaporizes, allowing atoms or molecules to condense onto a substrate, forming thin films. This physical vapor deposition method typically uses resistive or electron beam heating to achieve temperatures high enough for evaporation. Your choice between sputtered targets and evaporation sources depends on factors like film uniformity, deposition rate, and material compatibility.

Material Compatibility and Flexibility

Sputtered targets offer superior material compatibility with a wide range of metals, alloys, and ceramics due to their physical bombardment deposition process, enabling precise thin-film compositions on various substrates. Evaporation sources provide greater flexibility for depositing materials with low melting points or complex compounds by controlling the evaporation temperature and rate, though they may face challenges with uniformity and target purity. Both techniques complement each other in thin-film technology, with sputtering excelling in material diversity and evaporation favoring versatility for specialized applications.

Film Quality and Uniformity Comparison

Sputtered targets typically produce films with higher density and better adhesion, resulting in superior film quality compared to evaporation sources. The sputtering process offers enhanced uniformity over large substrates due to the more isotropic nature of particle ejection, while evaporation sources often face challenges like directional flux leading to thickness non-uniformity. Your choice between sputtering and evaporation should consider the specific film quality and uniformity requirements of your application for optimal results.

Deposition Rate and Process Control

Sputtered targets offer lower deposition rates compared to evaporation sources but provide superior process control due to enhanced uniformity and precise film composition. Evaporation sources achieve higher deposition rates by rapidly vaporizing materials, though they often face challenges in controlling film thickness and stoichiometry. Optimizing deposition rate and process control depends on balancing target material properties with the specific application requirements of sputtering or evaporation techniques.

Cost, Scalability, and Maintenance

Sputtered targets generally have higher initial costs compared to evaporation sources due to the complexity of their equipment and materials, but they offer greater scalability for uniform thin-film deposition across large substrates. Evaporation sources are more cost-effective for small-scale applications but face limitations in scaling up because of non-uniform coating and material wastage. Maintenance of sputtering systems tends to be more intensive and expensive, requiring routine target replacement and chamber cleaning, whereas evaporation sources have simpler upkeep with less frequent component wear.

Common Applications and Industrial Use Cases

Sputtered targets are widely used in semiconductor manufacturing, hard coating deposition, and magnetic storage devices due to their precise film thickness control and ability to deposit complex alloys. Evaporation sources find common applications in optical coatings, solar cells, and decorative finishes, where high deposition rates and smooth films are essential. Both methods serve critical roles in microelectronics fabrication and thin-film technology across industries like aerospace, automotive, and electronics manufacturing.

Summary: Choosing Between Sputtering and Evaporation

Sputtered targets offer superior film adhesion and uniformity, making them ideal for complex materials and applications requiring precise thin film deposition. Evaporation sources provide higher deposition rates and are typically more cost-effective for simpler, high-volume coatings. You should select sputtering when film quality and composition control are critical, while evaporation suits applications demanding speed and lower production costs.

Sputtered target vs Evaporation source Infographic

electrown.com

electrown.com