NiZn ferrite offers higher electrical resistivity and better performance at high frequencies, making it ideal for RF applications, while MnZn ferrite provides superior magnetic permeability and saturation magnetization suited for low-frequency transformers and inductors. Discover how choosing between NiZn and MnZn ferrite can impact your electronic device's efficiency by reading the rest of the article.

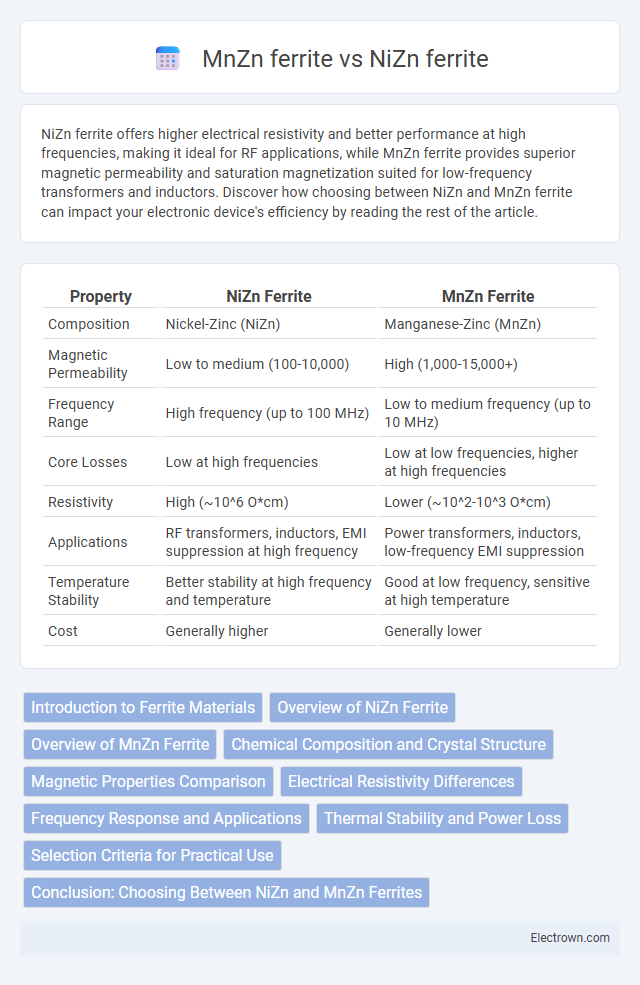

Table of Comparison

| Property | NiZn Ferrite | MnZn Ferrite |

|---|---|---|

| Composition | Nickel-Zinc (NiZn) | Manganese-Zinc (MnZn) |

| Magnetic Permeability | Low to medium (100-10,000) | High (1,000-15,000+) |

| Frequency Range | High frequency (up to 100 MHz) | Low to medium frequency (up to 10 MHz) |

| Core Losses | Low at high frequencies | Low at low frequencies, higher at high frequencies |

| Resistivity | High (~10^6 O*cm) | Lower (~10^2-10^3 O*cm) |

| Applications | RF transformers, inductors, EMI suppression at high frequency | Power transformers, inductors, low-frequency EMI suppression |

| Temperature Stability | Better stability at high frequency and temperature | Good at low frequency, sensitive at high temperature |

| Cost | Generally higher | Generally lower |

Introduction to Ferrite Materials

NiZn ferrites exhibit high resistivity and are preferred for high-frequency applications due to their low eddy current losses, while MnZn ferrites offer higher magnetic permeability suitable for low to medium frequency uses. NiZn ferrites typically operate efficiently above 1 MHz, making them ideal in RF transformers and antennas, whereas MnZn ferrites are common in power transformers and inductors operating below 1 MHz. The distinct electrical and magnetic properties of NiZn and MnZn ferrites arise from their differing compositions, influencing their performance in electronic and electromagnetic devices.

Overview of NiZn Ferrite

NiZn ferrite is a type of soft magnetic material characterized by high electrical resistivity and moderate saturation magnetization, making it ideal for high-frequency applications such as inductors and transformers. Its composition of nickel (Ni) and zinc (Zn) oxides enhances its performance in RF circuits by reducing eddy current losses compared to MnZn ferrite. You can rely on NiZn ferrite for efficient energy conversion in frequencies typically above 1 MHz, where MnZn ferrite's lower resistivity limits effectiveness.

Overview of MnZn Ferrite

MnZn ferrite is a soft magnetic material widely used in high-frequency transformer cores and inductors due to its high permeability and low power loss. Its composition, primarily manganese and zinc oxides, allows for efficient magnetic flux conduction, making it ideal for power electronics and RF applications. Understanding MnZn ferrite's properties can help you select the best core material for optimizing your device's performance and efficiency.

Chemical Composition and Crystal Structure

NiZn ferrite, composed primarily of nickel, zinc, and iron oxides, features a spinel crystal structure that offers high electrical resistivity, making it ideal for high-frequency applications. MnZn ferrite consists mainly of manganese, zinc, and iron oxides, with a similar spinel structure but lower resistivity, which enhances magnetic permeability suitable for lower-frequency uses. Your choice between NiZn and MnZn ferrites should consider the chemical composition's impact on crystal structure and electrical properties to optimize performance for specific frequency ranges.

Magnetic Properties Comparison

NiZn ferrite exhibits higher electrical resistivity and better high-frequency performance, making it ideal for applications above 1 MHz, while MnZn ferrite offers superior magnetic permeability and saturation magnetization suitable for low-frequency transformers and inductors. NiZn ferrites typically have a permeability range of 10 to 1000 with lower core losses at high frequencies, whereas MnZn ferrites reach permeability values up to 15,000 but exhibit increased losses above several hundred kHz. The choice between NiZn and MnZn ferrites depends on balancing magnetic permeability, frequency operating range, and core loss for specific electronic applications.

Electrical Resistivity Differences

NiZn ferrites exhibit significantly higher electrical resistivity, often exceeding 10^6 ohm*cm, compared to MnZn ferrites, which typically range around 10^2 to 10^4 ohm*cm. This higher resistivity in NiZn ferrite reduces eddy current losses, making it ideal for high-frequency applications above 1 MHz. In contrast, MnZn ferrite's lower resistivity suits lower-frequency applications due to its superior magnetic permeability but results in increased power loss at higher frequencies.

Frequency Response and Applications

NiZn ferrite exhibits higher resistivity and is effective in high-frequency applications ranging from several MHz up to GHz, making it ideal for RF transformers, antennas, and EMI suppression. MnZn ferrite has lower resistivity but superior magnetic permeability, performing efficiently in low to medium frequency ranges typically below 2 MHz, suited for power transformers, inductors, and electromagnetic interference filters in power electronics. The choice between NiZn and MnZn ferrites depends on the frequency range and application requirements, with NiZn preferred for high-frequency and MnZn for power and low-frequency applications.

Thermal Stability and Power Loss

NiZn ferrites exhibit superior thermal stability with a Curie temperature typically above 250degC, making them ideal for high-frequency applications where temperature fluctuations are significant. MnZn ferrites, while offering lower power loss at low frequencies due to their higher initial permeability, generally have lower thermal stability with Curie temperatures around 100-200degC. The power loss in NiZn ferrites remains relatively low at high frequencies up to several MHz, whereas MnZn ferrites experience increased losses beyond a few hundred kHz, limiting their effectiveness in high-frequency power applications.

Selection Criteria for Practical Use

NiZn ferrite is preferred for high-frequency applications above 1 MHz due to its high resistivity and low eddy current losses, making it ideal for RF transformers and inductors. MnZn ferrite offers higher magnetic permeability and saturation flux density, suitable for low to medium frequency applications below 1 MHz such as power transformers and inductors. Selection depends on operating frequency, permeability requirements, and power handling capacity, with NiZn favored for high-frequency, low power, and MnZn for high power and lower frequency environments.

Conclusion: Choosing Between NiZn and MnZn Ferrites

NiZn ferrites offer higher electrical resistivity, making them ideal for high-frequency applications above 1 MHz, while MnZn ferrites provide superior magnetic permeability suitable for low-frequency devices such as transformers and inductors up to 1 MHz. Your choice depends on the operating frequency and required magnetic properties, with NiZn favored for RF components and MnZn chosen for power electronics. Selecting the appropriate ferrite material optimizes performance, reduces core losses, and enhances overall device efficiency.

NiZn ferrite vs MnZn ferrite Infographic

electrown.com

electrown.com