PDMS offers excellent flexibility and biocompatibility, making it ideal for microfluidic devices and soft lithography, while SU-8 provides high-resolution, robust patterning suitable for creating high-aspect-ratio microstructures in photolithography applications. Discover how your choice between PDMS and SU-8 can impact the performance and durability of your microfabrication projects by reading the full comparison.

Table of Comparison

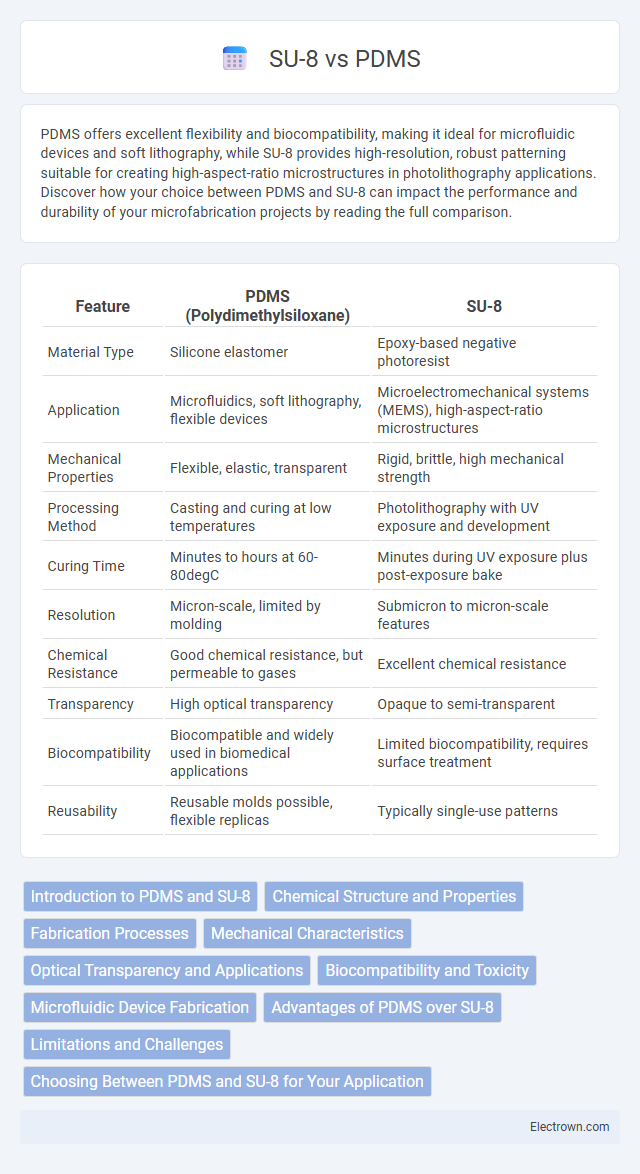

| Feature | PDMS (Polydimethylsiloxane) | SU-8 |

|---|---|---|

| Material Type | Silicone elastomer | Epoxy-based negative photoresist |

| Application | Microfluidics, soft lithography, flexible devices | Microelectromechanical systems (MEMS), high-aspect-ratio microstructures |

| Mechanical Properties | Flexible, elastic, transparent | Rigid, brittle, high mechanical strength |

| Processing Method | Casting and curing at low temperatures | Photolithography with UV exposure and development |

| Curing Time | Minutes to hours at 60-80degC | Minutes during UV exposure plus post-exposure bake |

| Resolution | Micron-scale, limited by molding | Submicron to micron-scale features |

| Chemical Resistance | Good chemical resistance, but permeable to gases | Excellent chemical resistance |

| Transparency | High optical transparency | Opaque to semi-transparent |

| Biocompatibility | Biocompatible and widely used in biomedical applications | Limited biocompatibility, requires surface treatment |

| Reusability | Reusable molds possible, flexible replicas | Typically single-use patterns |

Introduction to PDMS and SU-8

PDMS (Polydimethylsiloxane) is a silicone-based organic polymer widely used in microfluidics and soft lithography due to its flexibility, optical transparency, and biocompatibility. SU-8 is a high-contrast, epoxy-based negative photoresist known for creating high-aspect-ratio microstructures used in MEMS (Micro-Electro-Mechanical Systems) and microfabrication. Your choice between PDMS and SU-8 depends on the required mechanical properties and application, with PDMS offering elastomeric flexibility and SU-8 providing rigid, durable features.

Chemical Structure and Properties

PDMS, or polydimethylsiloxane, is a silicon-based organic polymer characterized by its repeating unit of -[Si(CH3)2-O]-, which imparts flexibility, chemical inertness, and hydrophobicity. SU-8 is an epoxy-based negative photoresist composed of multifunctional epoxide groups linked to an aliphatic hydrocarbon backbone, providing high chemical resistance, mechanical strength, and thermal stability. The chemical structure of PDMS enables elastomeric properties ideal for microfluidics, while SU-8's crosslinked epoxy network offers rigidity and fine patterning in microfabrication.

Fabrication Processes

PDMS fabrication involves soft lithography techniques utilizing spin-coating liquid polymer over molds followed by curing at elevated temperatures to form flexible microstructures. SU-8 fabrication relies on photolithography with UV exposure on a negative photoresist to create high-aspect-ratio, rigid microfeatures on substrates. The PDMS process enables rapid prototyping and elasticity, while SU-8 provides superior mechanical strength and chemical resistance suitable for permanent microelectromechanical systems (MEMS).

Mechanical Characteristics

PDMS exhibits excellent flexibility and elasticity with a low Young's modulus around 0.36-0.87 MPa, making it ideal for stretchable and bendable microfluidic devices. SU-8, in contrast, has a high Young's modulus of approximately 2-4 GPa, providing superior rigidity and mechanical stability for high-aspect-ratio microstructures. Your choice depends on whether you require soft, pliable materials or stiff, durable resin in your application.

Optical Transparency and Applications

PDMS offers excellent optical transparency with over 90% transmittance in the visible spectrum, making it ideal for microfluidic devices requiring real-time optical analysis. SU-8, while also transparent, exhibits higher absorption in the UV range but provides superior mechanical stability, suitable for high-aspect-ratio microstructures in photolithography. Applications leveraging PDMS include lab-on-chip sensors and optical waveguides, whereas SU-8 is preferred for MEMS fabrication and microelectromechanical systems due to its durability.

Biocompatibility and Toxicity

PDMS (Polydimethylsiloxane) is widely recognized for its excellent biocompatibility, making it suitable for long-term implantation and cellular studies due to its inert, non-toxic nature. SU-8, a negative photoresist used in microfabrication, exhibits inherent cytotoxicity primarily from unpolymerized residues, necessitating thorough post-processing treatments to enhance biocompatibility. Comparative studies demonstrate that PDMS supports better cell adhesion and proliferation, whereas SU-8 requires surface modification to reduce toxicity and improve compatibility with biological tissues.

Microfluidic Device Fabrication

PDMS offers excellent flexibility and biocompatibility, making it ideal for rapid prototyping of microfluidic devices with complex channel geometries. SU-8, a negative epoxy-based photoresist, provides high-resolution patterning and robust mechanical stability, essential for durable microfluidic structures requiring precise feature definition. Your choice between PDMS and SU-8 depends on the specific application requirements, such as elasticity, chemical resistance, and resolution accuracy in device fabrication.

Advantages of PDMS over SU-8

PDMS offers superior flexibility and elasticity compared to SU-8, making it ideal for applications requiring mechanical deformation or stretchability. Its biocompatibility and gas permeability enhance cell culture and microfluidic device functionality, which SU-8 lacks due to its rigid and brittle nature. PDMS also allows for simpler and faster fabrication processes with easier molding and bonding, reducing production time and cost relative to SU-8 photolithography.

Limitations and Challenges

PDMS exhibits limitations such as permeability to gases and solvents, mechanical instability under high pressure, and swelling in organic solvents, which can affect microfluidic device performance. SU-8 presents challenges including brittleness, difficulty in achieving uniform thickness for thick layers, and limited biocompatibility without surface modifications. Your choice between PDMS and SU-8 should consider these material-specific drawbacks in relation to the intended application requirements.

Choosing Between PDMS and SU-8 for Your Application

PDMS offers excellent flexibility, transparency, and biocompatibility, making it suitable for microfluidic devices and cell culture platforms, while SU-8 provides high mechanical strength, chemical resistance, and precise patterning capabilities ideal for microfabrication and photolithography. Selecting between PDMS and SU-8 depends on factors such as the required structural rigidity, resolution of microfeatures, and chemical environment of the application. PDMS is preferred for applications needing elasticity and gas permeability, whereas SU-8 is advantageous for durable, high-aspect-ratio microstructures.

PDMS vs SU-8 Infographic

electrown.com

electrown.com