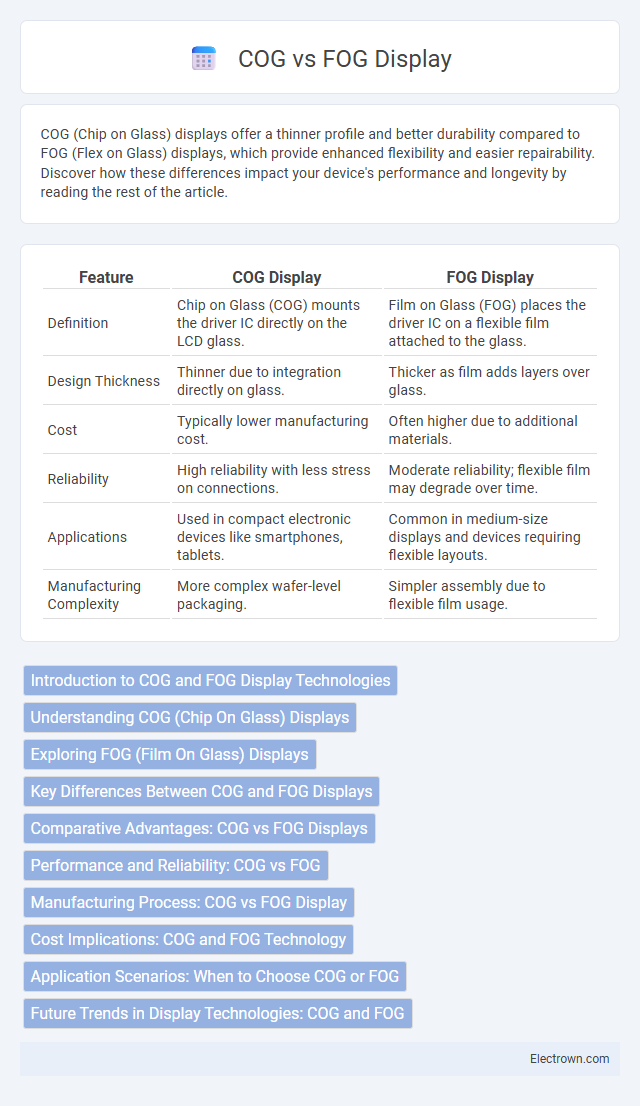

COG (Chip on Glass) displays offer a thinner profile and better durability compared to FOG (Flex on Glass) displays, which provide enhanced flexibility and easier repairability. Discover how these differences impact your device's performance and longevity by reading the rest of the article.

Table of Comparison

| Feature | COG Display | FOG Display |

|---|---|---|

| Definition | Chip on Glass (COG) mounts the driver IC directly on the LCD glass. | Film on Glass (FOG) places the driver IC on a flexible film attached to the glass. |

| Design Thickness | Thinner due to integration directly on glass. | Thicker as film adds layers over glass. |

| Cost | Typically lower manufacturing cost. | Often higher due to additional materials. |

| Reliability | High reliability with less stress on connections. | Moderate reliability; flexible film may degrade over time. |

| Applications | Used in compact electronic devices like smartphones, tablets. | Common in medium-size displays and devices requiring flexible layouts. |

| Manufacturing Complexity | More complex wafer-level packaging. | Simpler assembly due to flexible film usage. |

Introduction to COG and FOG Display Technologies

COG (Chip on Glass) and FOG (Flexible on Glass) display technologies offer innovative solutions for integrating electronic components with glass substrates in modern screens. COG embeds semiconductor chips directly onto the glass panel, enhancing display performance and reducing assembly complexity, while FOG uses flexible circuits laminated onto glass, providing greater design flexibility and durability. Understanding these technologies helps you choose the right display type for applications requiring compactness, high resolution, and reliability.

Understanding COG (Chip On Glass) Displays

COG (Chip On Glass) displays integrate the IC chip directly onto the glass substrate, reducing size and improving display clarity by minimizing connection distances. This technology enhances durability and allows for thinner, lightweight screens ideal for compact devices like smartphones and smartwatches. Your choice of COG displays ensures high-resolution output with efficient power consumption compared to traditional FOG (Flexible On Glass) alternatives.

Exploring FOG (Film On Glass) Displays

FOG (Film On Glass) displays deliver enhanced durability and superior visual clarity by integrating thin film layers directly onto glass substrates, making them ideal for rugged applications and high-resolution screens. Unlike COG (Chip On Glass) displays, where the chip is mounted directly onto the glass, FOG technology reduces interference and improves tactile responsiveness through its laminated film structure. This innovative approach streamlines manufacturing processes while optimizing display performance in industrial, automotive, and wearable devices.

Key Differences Between COG and FOG Displays

COG (Chip on Glass) displays integrate the driver IC directly onto the glass substrate, resulting in a thinner, more compact design with improved reliability and lower manufacturing costs. FOG (Flexible on Glass) displays attach flexible circuit boards to the glass, allowing for enhanced flexibility and durability in bending applications but often increasing thickness and complexity. The key differences lie in form factor, manufacturing complexity, and suitability for flexible versus rigid applications, with COG favoring slim, rigid displays and FOG supporting bendable, resilient screens.

Comparative Advantages: COG vs FOG Displays

COG (Chip on Glass) displays offer superior compactness and improved signal integrity by directly mounting the driver chip onto the glass substrate, reducing size and enhancing display performance. FOG (Flexible on Glass) displays provide greater flexibility and durability with bendable substrates, ideal for curved or wearable device screens requiring resilience to mechanical stress. Your choice between COG and FOG depends on whether you prioritize compact, high-resolution display integration or flexible, robust screen applications.

Performance and Reliability: COG vs FOG

COG (Chip on Glass) displays offer superior performance with higher resolution and faster response times due to direct chip integration, minimizing signal loss and interference. FOG (Flexible on Glass) displays provide enhanced reliability through flexible circuit designs that accommodate bending and reduce mechanical stress, extending device lifespan. While COG excels in sharp image quality and speed, FOG ensures durability and consistent functionality in flexible and wearable applications.

Manufacturing Process: COG vs FOG Display

COG (Chip on Glass) displays integrate the driver IC directly onto the glass substrate, allowing for a streamlined manufacturing process that reduces component count and assembly steps. FOG (Flexible on Glass) displays, on the other hand, attach flexible circuits to the glass, enabling greater design flexibility but involving more complex lamination and alignment processes. Your choice between COG and FOG impacts production efficiency, cost, and display durability based on these distinct manufacturing techniques.

Cost Implications: COG and FOG Technology

COG (Chip-On-Glass) technology generally offers lower manufacturing costs due to fewer assembly steps and reduced material usage, making it a cost-effective solution for high-volume display production. FOG (Flexible-On-Glass) technology, while more expensive, provides enhanced flexibility and improved durability, which can justify the higher investment for applications requiring robust and bendable displays. Evaluating your project's budget and performance requirements helps determine the optimal balance between cost efficiency and advanced functionality inherent in COG and FOG displays.

Application Scenarios: When to Choose COG or FOG

COG displays are ideal for compact, space-constrained devices such as smartwatches, wearable health monitors, and handheld gadgets due to their thin profile and high durability. FOG displays excel in applications requiring larger screen sizes and better heat dissipation, such as tablets, automotive dashboards, and industrial control panels. Selecting COG or FOG depends on prioritizing device form factor, thermal management, and manufacturing cost constraints.

Future Trends in Display Technologies: COG and FOG

Future trends in display technologies emphasize the evolution of Chip-on-Glass (COG) and Flexible on Glass (FOG) displays, with COG offering enhanced integration by directly mounting ICs onto glass substrates for compact, high-resolution panels. FOG technology advances flexibility and durability, enabling bendable and foldable screens ideal for next-generation wearable devices and rollable displays. Your choice between COG and FOG will depend on the desired balance between rigidity and flexibility in cutting-edge display applications.

COG vs FOG display Infographic

electrown.com

electrown.com