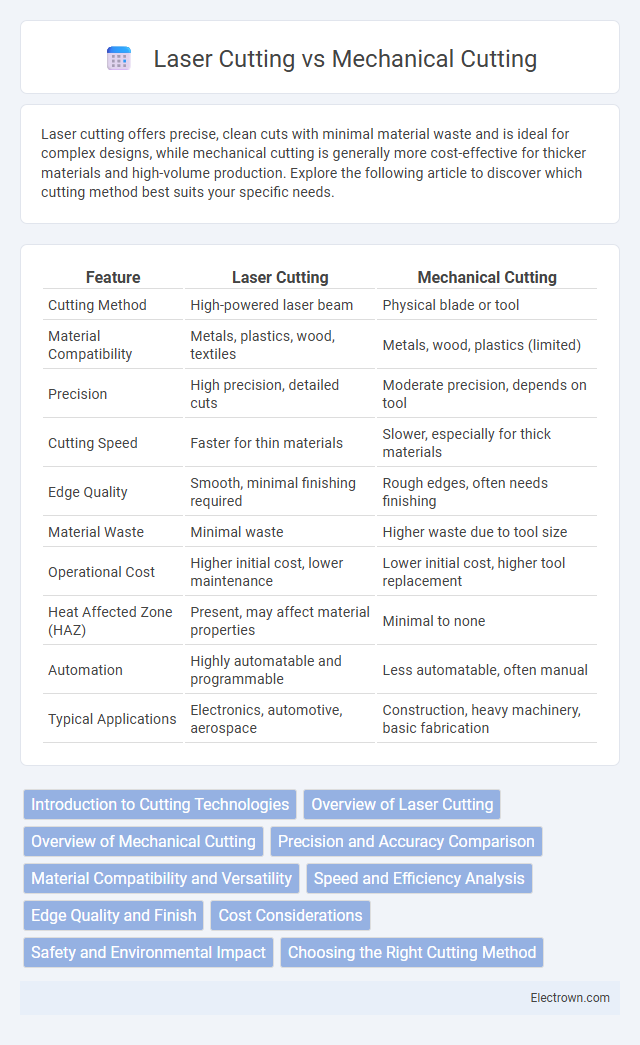

Laser cutting offers precise, clean cuts with minimal material waste and is ideal for complex designs, while mechanical cutting is generally more cost-effective for thicker materials and high-volume production. Explore the following article to discover which cutting method best suits your specific needs.

Table of Comparison

| Feature | Laser Cutting | Mechanical Cutting |

|---|---|---|

| Cutting Method | High-powered laser beam | Physical blade or tool |

| Material Compatibility | Metals, plastics, wood, textiles | Metals, wood, plastics (limited) |

| Precision | High precision, detailed cuts | Moderate precision, depends on tool |

| Cutting Speed | Faster for thin materials | Slower, especially for thick materials |

| Edge Quality | Smooth, minimal finishing required | Rough edges, often needs finishing |

| Material Waste | Minimal waste | Higher waste due to tool size |

| Operational Cost | Higher initial cost, lower maintenance | Lower initial cost, higher tool replacement |

| Heat Affected Zone (HAZ) | Present, may affect material properties | Minimal to none |

| Automation | Highly automatable and programmable | Less automatable, often manual |

| Typical Applications | Electronics, automotive, aerospace | Construction, heavy machinery, basic fabrication |

Introduction to Cutting Technologies

Laser cutting offers precise, high-speed material processing with minimal mechanical stress, using focused laser beams to vaporize or melt materials. Mechanical cutting involves traditional methods such as shearing, milling, or sawing, relying on physical contact and force to reshape materials. Your choice between laser and mechanical cutting depends on factors like material type, required precision, production volume, and cost efficiency.

Overview of Laser Cutting

Laser cutting uses a high-powered laser beam to precisely cut materials by melting, burning, or vaporizing them, resulting in clean edges and minimal material waste. This technique is ideal for intricate designs and thin to medium-thickness materials, providing speed and high accuracy. Laser cutting is commonly applied in industries such as aerospace, automotive, and electronics for metal, plastic, and wood fabrication.

Overview of Mechanical Cutting

Mechanical cutting uses physical tools such as blades, saws, or drills to remove material through shear or abrasion, making it suitable for metals, plastics, and wood. This method offers precision in shaping parts and can be more cost-effective for thicker materials or simple geometries. Mechanical cutting's main limitations include tool wear, slower processing speeds compared to laser cutting, and less capability for intricate or highly detailed designs.

Precision and Accuracy Comparison

Laser cutting offers superior precision and accuracy compared to mechanical cutting, achieving tolerances as tight as +-0.1 mm due to its focused laser beam and minimal tool wear. Mechanical cutting methods, such as milling or sawing, typically have lower precision because of tool deflection and material deformation, resulting in tolerances around +-0.5 mm. The non-contact nature of laser cutting ensures consistent accuracy across complex geometries, while mechanical cutting may suffer from variability in thicker or harder materials.

Material Compatibility and Versatility

Laser cutting offers exceptional compatibility with a wide range of materials, including metals, plastics, wood, and fabrics, enabling precise and intricate designs that mechanical cutting often cannot achieve. Mechanical cutting is typically limited to thicker or tougher materials like metal sheets and hard plastics, but may struggle with delicate or heat-sensitive substances. Your choice should consider the specific material and required versatility, as laser cutting adapts more flexibly to various thicknesses and complex geometries.

Speed and Efficiency Analysis

Laser cutting offers superior speed and precision compared to mechanical cutting, enabling faster processing of complex designs with minimal material waste. Mechanical cutting often requires tool changes and maintenance interruptions, reducing overall efficiency and increasing production time. Your choice of cutting method directly impacts turnaround time and cost-effectiveness, especially in industries demanding high-volume, intricate component fabrication.

Edge Quality and Finish

Laser cutting provides superior edge quality with minimal burr and smooth finishes, ideal for intricate and precise designs; it produces clean, sharp edges due to its non-contact process and focused heat application. Mechanical cutting often results in rougher edges with potential for burr formation and requires additional finishing processes to achieve comparable smoothness. The choice between laser and mechanical cutting depends on the material type, thickness, and required edge precision for the final application.

Cost Considerations

Laser cutting typically incurs higher initial equipment costs but offers lower operational expenses due to reduced material waste and faster processing times. Mechanical cutting features lower upfront investment but may demand increased maintenance and tooling expenses over time. Evaluating production volume and precision requirements is crucial for optimizing overall cost efficiency between the two methods.

Safety and Environmental Impact

Laser cutting significantly reduces physical hazards by minimizing direct contact with cutting tools and producing less debris compared to mechanical cutting. The process generates fewer airborne contaminants and waste materials, contributing to a lower environmental footprint. Mechanical cutting often involves sharp tools and moving parts that pose higher risks of injury, while producing metal shavings and dust that require careful disposal to prevent environmental contamination.

Choosing the Right Cutting Method

Selecting the right cutting method depends on material type, thickness, and precision requirements; laser cutting excels in high precision and complex designs for metals, plastics, and thin materials, while mechanical cutting is better suited for thicker, tougher materials like wood or heavy metals. Laser cutting offers minimal material wastage and cleaner edges due to its non-contact process, reducing the need for secondary finishing. Mechanical cutting remains cost-effective for simple, repetitive cuts and large-scale production of durable materials where speed is prioritized over intricate detail.

Laser cutting vs Mechanical cutting Infographic

electrown.com

electrown.com