Molded Case Circuit Breakers (MCCB) offer adjustable trip settings and higher current ratings, making them ideal for customized protection in industrial applications, while Air Circuit Breakers (ACB) provide superior short-circuit breaking capacity and are suited for low-voltage power distribution systems. Explore the rest of this article to understand which breaker best fits Your electrical safety needs.

Table of Comparison

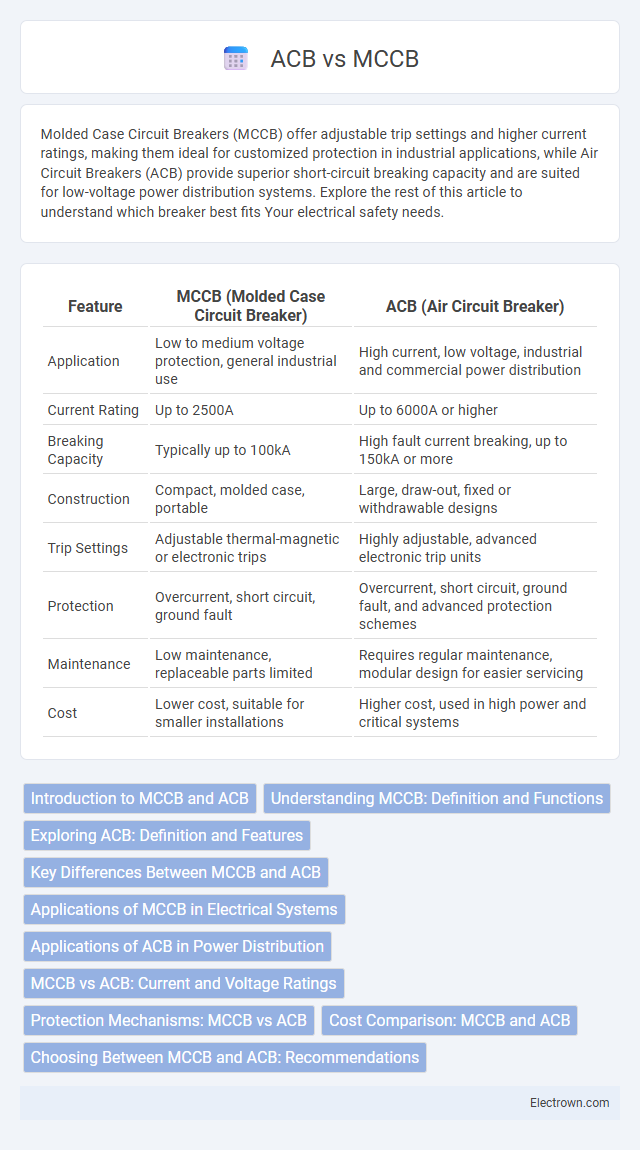

| Feature | MCCB (Molded Case Circuit Breaker) | ACB (Air Circuit Breaker) |

|---|---|---|

| Application | Low to medium voltage protection, general industrial use | High current, low voltage, industrial and commercial power distribution |

| Current Rating | Up to 2500A | Up to 6000A or higher |

| Breaking Capacity | Typically up to 100kA | High fault current breaking, up to 150kA or more |

| Construction | Compact, molded case, portable | Large, draw-out, fixed or withdrawable designs |

| Trip Settings | Adjustable thermal-magnetic or electronic trips | Highly adjustable, advanced electronic trip units |

| Protection | Overcurrent, short circuit, ground fault | Overcurrent, short circuit, ground fault, and advanced protection schemes |

| Maintenance | Low maintenance, replaceable parts limited | Requires regular maintenance, modular design for easier servicing |

| Cost | Lower cost, suitable for smaller installations | Higher cost, used in high power and critical systems |

Introduction to MCCB and ACB

Molded Case Circuit Breakers (MCCBs) are designed for protecting electrical circuits from overload, short circuits, and faults with a frame size typically up to 1600 amps, widely used in industrial and commercial applications. Air Circuit Breakers (ACBs) provide high-capacity protection beyond MCCB limits, generally above 1600 amps, offering advanced features such as adjustable trip settings and enhanced fault interruption for low voltage power distribution systems. Both MCCBs and ACBs play critical roles in electrical safety but differ significantly in their application scope, interrupting capacity, and installation environments.

Understanding MCCB: Definition and Functions

Molded Case Circuit Breakers (MCCBs) are electrical protection devices designed to safeguard circuits from overcurrent, short circuits, and electrical faults by automatically interrupting the current flow. MCCBs provide adjustable trip settings and are suitable for low-voltage applications up to 1,000 amps, enabling precise protection for various industrial and commercial electrical systems. Their compact, modular design allows for easy installation and maintenance, ensuring reliable performance in diverse operational environments.

Exploring ACB: Definition and Features

Air Circuit Breakers (ACB) are high-capacity electrical protection devices designed to manage and interrupt large current loads in low-voltage distribution systems, providing superior fault isolation and system protection. Unlike Molded Case Circuit Breakers (MCCB), ACBs offer advanced features such as adjustable trip settings, higher breaking capacity, and integrated communication capabilities for monitoring and control in industrial applications. Understanding your system's requirements is crucial for selecting an ACB that ensures optimal electrical safety and operational reliability.

Key Differences Between MCCB and ACB

Molded Case Circuit Breakers (MCCB) are typically used for low to medium voltage applications, providing circuit protection up to 1600 amps with adjustable trip settings. Air Circuit Breakers (ACB) are designed for higher current ratings, usually above 1600 amps, and offer enhanced protection features such as instant tripping and better fault interrupting capacity. MCCBs are compact and suited for panel-mounted applications, while ACBs are larger, used in industrial settings for main power distribution and higher fault current handling.

Applications of MCCB in Electrical Systems

Molded Case Circuit Breakers (MCCBs) are widely used in electrical systems for protecting circuits and equipment from overloads and short circuits in residential, commercial, and industrial applications. MCCBs provide reliable protection in panelboards, motor control centers, and distribution boards, handling current ratings typically from 15A to 1600A. Their compact design and adjustable trip settings make MCCBs ideal for safeguarding wiring, transformers, and various electronic devices in medium voltage systems.

Applications of ACB in Power Distribution

Air Circuit Breakers (ACBs) are primarily used in low voltage power distribution systems for protecting electrical circuits from overload and short circuits in industrial plants, commercial buildings, and power substations. ACBs handle high current ratings and enable easy maintenance and replacement due to their modular design and adjustable trip settings. Their ability to interrupt large fault currents makes them ideal for main distribution panels and critical load management in power distribution networks.

MCCB vs ACB: Current and Voltage Ratings

MCCBs (Molded Case Circuit Breakers) typically handle current ratings up to 2500 amps and voltage ratings up to 1000 volts AC, suitable for low to medium voltage applications. ACBs (Air Circuit Breakers) support higher current ratings, often exceeding 6000 amps, and voltage ratings up to 690 volts AC, making them ideal for high current, low voltage industrial systems. The choice between MCCB and ACB depends on the load requirements, with ACBs offering greater capacity and adjustable trip settings for large-scale electrical protection.

Protection Mechanisms: MCCB vs ACB

MCCBs (Molded Case Circuit Breakers) provide reliable short-circuit and overload protection tailored for low to medium voltage applications, with adjustable trip settings enhancing fault detection. ACBs (Air Circuit Breakers) offer advanced protection mechanisms including ground fault and sophisticated thermal-magnetic or electronic trip units for high-capacity circuits, ensuring precise fault isolation. Your choice between MCCB and ACB depends on the specific protection requirements, current rating, and system complexity needed for optimal safety.

Cost Comparison: MCCB and ACB

Molded Case Circuit Breakers (MCCB) typically offer lower initial costs compared to Air Circuit Breakers (ACB), making them suitable for medium-voltage applications with budget constraints. ACBs, designed for higher current ratings and advanced protection features, involve higher upfront expenses but provide greater reliability and customization for industrial settings. Long-term maintenance and operational costs for ACBs may be lower due to their superior durability and built-in advanced trip units, which can justify the higher initial investment.

Choosing Between MCCB and ACB: Recommendations

Choosing between MCCB (Molded Case Circuit Breaker) and ACB (Air Circuit Breaker) depends on your electrical system's voltage, current ratings, and protection requirements. MCCBs are ideal for lower power distribution and overload protection up to 1000 amps, while ACBs suit higher current applications often exceeding 1600 amps with advanced fault interruption capabilities. Your choice should align with system load capacity, selectivity, and maintenance preferences for optimal safety and performance.

MCCB vs ACB Infographic

electrown.com

electrown.com