Split core CTs offer easy installation without disconnecting existing circuits and are ideal for retrofit applications, while solid core CTs provide higher accuracy and stability for permanent installations. Understanding the differences between these current transformers can help optimize your electrical measurement setup--read on to learn more about their specific uses and benefits.

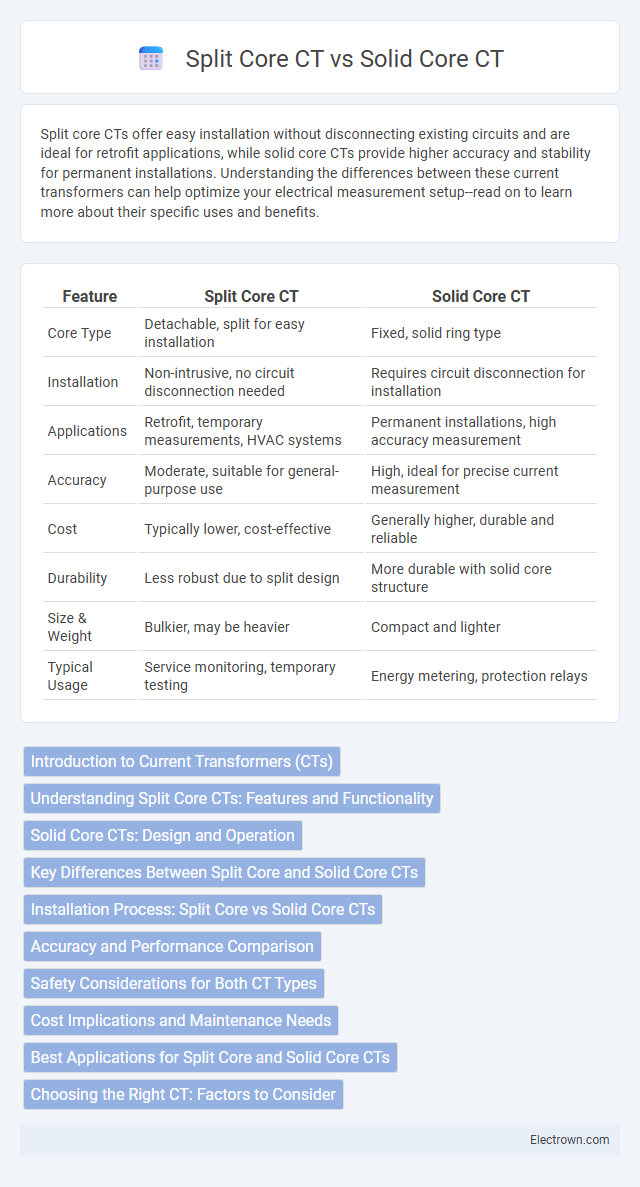

Table of Comparison

| Feature | Split Core CT | Solid Core CT |

|---|---|---|

| Core Type | Detachable, split for easy installation | Fixed, solid ring type |

| Installation | Non-intrusive, no circuit disconnection needed | Requires circuit disconnection for installation |

| Applications | Retrofit, temporary measurements, HVAC systems | Permanent installations, high accuracy measurement |

| Accuracy | Moderate, suitable for general-purpose use | High, ideal for precise current measurement |

| Cost | Typically lower, cost-effective | Generally higher, durable and reliable |

| Durability | Less robust due to split design | More durable with solid core structure |

| Size & Weight | Bulkier, may be heavier | Compact and lighter |

| Typical Usage | Service monitoring, temporary testing | Energy metering, protection relays |

Introduction to Current Transformers (CTs)

Current Transformers (CTs) are essential for measuring alternating current in electrical systems, converting high currents to manageable levels for instruments and protection devices. Solid core CTs provide reliable accuracy and durability with a fixed, continuous magnetic core, ideal for permanent installations, while split core CTs offer the advantage of easy installation without interrupting the circuit, making them suitable for retrofit applications. Understanding the differences between split core CT vs solid core CT helps you select the right type for precise current monitoring and safety in your electrical setup.

Understanding Split Core CTs: Features and Functionality

Split Core Current Transformers (CTs) offer the advantage of easy installation without disconnecting the power circuit, making them ideal for retrofitting or monitoring existing systems. Featuring a hinged design, these CTs provide accurate measurement by clamping around conductors, ensuring minimal disruption during setup. When selecting a CT for your system, consider that Split Core CTs balance convenience with reliable performance, especially in applications requiring quick deployment.

Solid Core CTs: Design and Operation

Solid Core CTs feature a continuous, ring-shaped magnetic core that provides higher accuracy and stability in current measurement. Their design ensures a consistent magnetic path, minimizing core losses and enhancing performance in high-current applications. Your system benefits from solid core CTs when precise, reliable current sensing is essential for effective monitoring and protection.

Key Differences Between Split Core and Solid Core CTs

Split Core CTs offer easy installation without disconnecting the circuit, ideal for retrofitting existing systems, while Solid Core CTs provide higher accuracy and durability for permanent installations. You gain flexibility with Split Core designs, as they allow quick measurement changes, whereas Solid Core CTs excel in environments requiring consistent, precise current monitoring. The key differences lie in installation convenience, accuracy levels, and application-specific suitability for electrical current measurement.

Installation Process: Split Core vs Solid Core CTs

Split Core CTs offer a faster installation process as their hinged design allows them to be placed around existing conductors without disconnecting the circuit, making them ideal for retrofit applications. Solid Core CTs require the power to be disconnected and the conductor to be threaded through the core during installation, ensuring higher accuracy but demanding more downtime. Your choice depends on whether ease of installation or measurement precision is the priority for your electrical system.

Accuracy and Performance Comparison

Split Core CTs offer convenient installation with moderate accuracy, making them suitable for retrofit applications, while Solid Core CTs provide superior accuracy and performance due to their single-piece construction that minimizes magnetic interference. Solid Core CTs excel in high-precision environments by delivering stable and consistent measurements, whereas Split Core CTs may suffer slight accuracy losses from gaps and mechanical stresses. Choosing between the two impacts your system's measurement reliability, especially in critical energy monitoring or protective relay applications.

Safety Considerations for Both CT Types

Split Core CTs offer enhanced safety by allowing installation without disconnecting the circuit, reducing shock hazards during setup, while Solid Core CTs require circuit interruption, increasing electrical risk. Both types must be properly insulated and rated for the system voltage to prevent electrical faults or overheating. Ensuring your CT choice aligns with safety protocols minimizes risk and protects your personnel and equipment during current measurement tasks.

Cost Implications and Maintenance Needs

Split Core CTs generally incur higher initial costs due to their complex design but reduce installation expenses by eliminating the need to disconnect existing wiring. Solid Core CTs are more cost-effective upfront but may require costly downtime and labor for installation or maintenance. Your choice impacts long-term maintenance needs, with Split Core CTs offering easier inspection and replacement compared to the durable yet less accessible Solid Core CTs.

Best Applications for Split Core and Solid Core CTs

Split Core CTs are best suited for retrofitting existing electrical systems where dismantling the conductor is impractical, making them ideal for temporary measurements and maintenance checks. Solid Core CTs provide higher accuracy and reliability, making them optimal for permanent installations in high-current environments such as industrial plants and power distribution networks. Choosing between Split Core and Solid Core CTs depends on installation convenience and the precision requirements of the specific application.

Choosing the Right CT: Factors to Consider

Choosing the right current transformer (CT) involves evaluating installation ease, accuracy requirements, and application environment. Split core CTs offer quick installation without disconnecting conductors, ideal for retrofit or maintenance situations, while solid core CTs provide higher accuracy and durability, suitable for new installations with stable conductor configurations. Consider factors such as accuracy class, conductor size, electrical load, and available installation time to determine the optimal CT type for your electrical system.

Split Core CT vs Solid Core CT Infographic

electrown.com

electrown.com