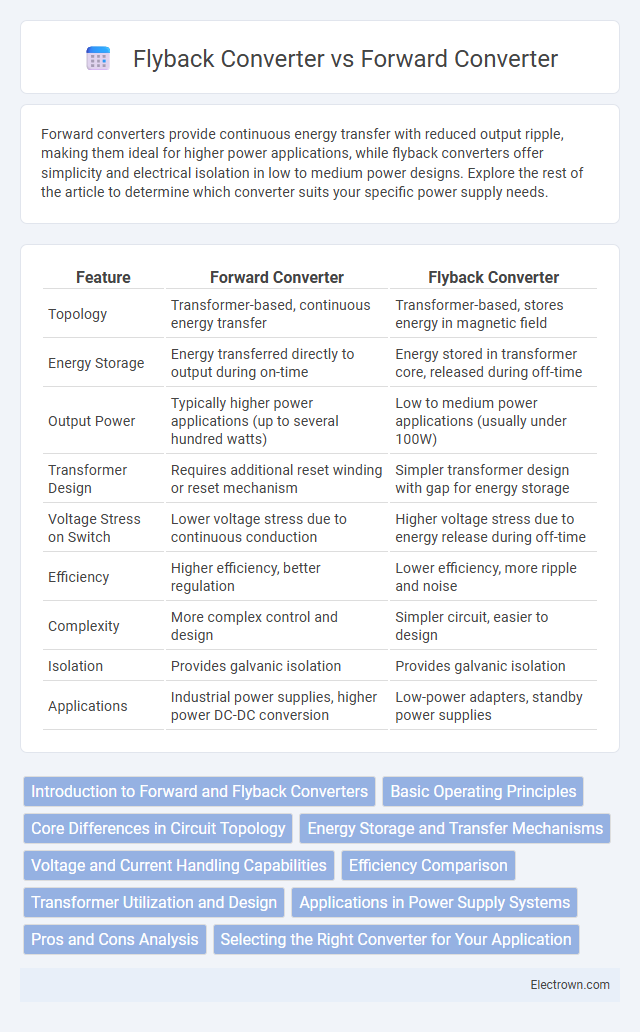

Forward converters provide continuous energy transfer with reduced output ripple, making them ideal for higher power applications, while flyback converters offer simplicity and electrical isolation in low to medium power designs. Explore the rest of the article to determine which converter suits your specific power supply needs.

Table of Comparison

| Feature | Forward Converter | Flyback Converter |

|---|---|---|

| Topology | Transformer-based, continuous energy transfer | Transformer-based, stores energy in magnetic field |

| Energy Storage | Energy transferred directly to output during on-time | Energy stored in transformer core, released during off-time |

| Output Power | Typically higher power applications (up to several hundred watts) | Low to medium power applications (usually under 100W) |

| Transformer Design | Requires additional reset winding or reset mechanism | Simpler transformer design with gap for energy storage |

| Voltage Stress on Switch | Lower voltage stress due to continuous conduction | Higher voltage stress due to energy release during off-time |

| Efficiency | Higher efficiency, better regulation | Lower efficiency, more ripple and noise |

| Complexity | More complex control and design | Simpler circuit, easier to design |

| Isolation | Provides galvanic isolation | Provides galvanic isolation |

| Applications | Industrial power supplies, higher power DC-DC conversion | Low-power adapters, standby power supplies |

Introduction to Forward and Flyback Converters

Forward and Flyback converters are essential DC-DC power supply topologies used in various electronic applications. The Forward Converter transfers energy directly to the output during the switch-on period, resulting in higher efficiency and lower output ripple, making it suitable for medium to high power levels. Flyback Converters store energy in a transformer during the switch-on phase and release it during switch-off, offering simple isolation and cost-effective designs ideal for low to medium power applications.

Basic Operating Principles

Forward converters utilize a transformer to transfer energy directly to the output during the switch-on period, enabling continuous energy flow and improved efficiency. Flyback converters store energy in the transformer's magnetic field during the switch-on phase and release it to the output when the switch is off, resulting in a simpler design suitable for lower power applications. The forward converter's operation relies on magnetizing and demagnetizing an auxiliary winding to reset the core, whereas the flyback converter functions as a coupled inductor with energy storage and release cycles.

Core Differences in Circuit Topology

A Forward Converter employs a transformer with an additional demagnetizing winding or reset circuit, allowing continuous energy transfer and efficient power conversion, while a Flyback Converter uses the transformer as an energy storage element with energy transferred discontinuously during the off-cycle. The Forward Converter's output inductor smooths current flow, resulting in lower output ripple compared to the Flyback's simpler design, which stores energy in the transformer core and releases it to the output during the switch off time. Your choice between these topologies depends on power level, efficiency needs, and complexity, with Forward Converters favored for higher power applications and Flyback Converters preferred in low-power, cost-sensitive designs.

Energy Storage and Transfer Mechanisms

The Forward Converter stores energy primarily in the transformer core and transfers it directly to the output via a secondary winding and output inductor, ensuring continuous energy flow during the switch-on period. In contrast, the Flyback Converter stores energy in the magnetic field of the transformer during the switch-on phase and releases it to the output during the off phase, functioning effectively as a coupled inductor. This difference influences efficiency and output ripple, with the Forward Converter typically achieving lower output voltage ripple due to its continuous energy transfer mechanism.

Voltage and Current Handling Capabilities

Forward converters excel in handling higher output currents due to their continuous energy transfer and use of a reliable transformer with an additional demagnetizing winding, making them suitable for medium to high power applications. Flyback converters are better suited for lower power levels with isolated outputs, as they store energy in the transformer's magnetic field and release it during the off period, which limits their current handling capabilities but allows simpler design and cost-effectiveness. Your choice depends on the application's power requirements, with forward converters providing superior voltage and current handling for demanding loads.

Efficiency Comparison

Forward converters typically achieve higher efficiency than flyback converters due to their continuous energy transfer and lower peak currents, resulting in reduced conduction and switching losses. Flyback converters, while simpler and cost-effective for low-power applications, experience higher losses from energy stored in the flyback transformer and increased stress on components. Efficiency in forward converters often exceeds 85-90% in medium to high power ranges, whereas flyback converters generally range around 75-85%, making forward topology preferable for applications demanding optimized power conversion efficiency.

Transformer Utilization and Design

The Forward Converter utilizes a transformer with a reset winding or clamp circuit to effectively transfer energy during the switch on-time, resulting in continuous energy flow and better transformer utilization compared to the Flyback Converter, which stores energy in the transformer core during the switch on-time and releases it during off-time, requiring careful design to avoid core saturation. Transformer design for Forward Converters involves selecting core materials and windings that handle continuous magnetizing current and accommodate reset mechanisms, whereas Flyback Converters demand cores with sufficient gap to store energy and precise calculation of magnetizing inductance to optimize energy transfer and minimize losses. The choice between these converters hinges on efficiency considerations tied to transformer design complexities and the specific application's power requirements, with Forward Converters typically offering higher efficiency in medium to high-power applications.

Applications in Power Supply Systems

Forward converters are ideal for medium to high-power applications such as industrial power supplies, telecommunications, and server power systems due to their efficient energy transfer and low output voltage ripple. Flyback converters excel in low to medium-power applications like battery chargers, standby power supplies, and small consumer electronics because of their simple design and ability to provide electrical isolation. Understanding the differences helps optimize your power supply design for specific voltage and power requirements.

Pros and Cons Analysis

Forward converters offer higher efficiency and better regulation for medium to high power applications, making them suitable for Your industrial power supplies, but they require complex transformers and multiple components which increase cost and size. Flyback converters excel in simplicity, compact design, and cost-effectiveness for low to medium power applications, yet they suffer from higher leakage inductance and electromagnetic interference, leading to lower efficiency. Choosing between these topologies depends on Your power requirements, space constraints, and efficiency priorities.

Selecting the Right Converter for Your Application

When selecting the right converter for your application, consider that forward converters offer higher efficiency and better voltage regulation for medium to high power levels, typically between 50W to 300W. Flyback converters are ideal for low power applications under 100W due to their simpler design and cost-effectiveness, but they tend to have higher output ripple and lower efficiency. Your specific power requirements, complexity tolerance, and isolation needs determine whether a forward or flyback converter suits your design best.

Forward Converter vs Flyback Converter Infographic

electrown.com

electrown.com