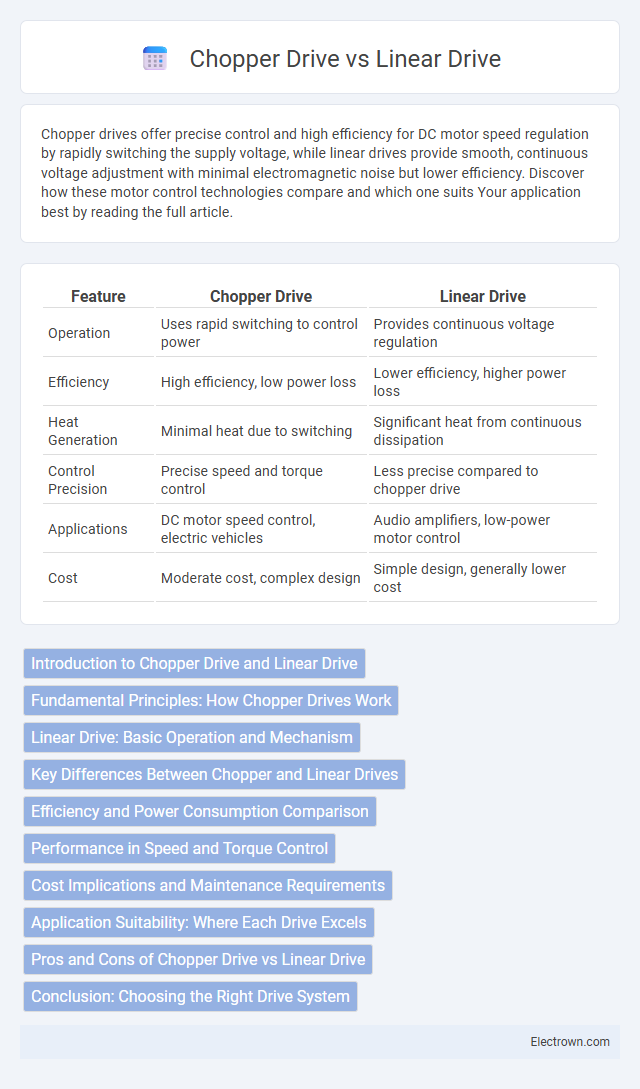

Chopper drives offer precise control and high efficiency for DC motor speed regulation by rapidly switching the supply voltage, while linear drives provide smooth, continuous voltage adjustment with minimal electromagnetic noise but lower efficiency. Discover how these motor control technologies compare and which one suits Your application best by reading the full article.

Table of Comparison

| Feature | Chopper Drive | Linear Drive |

|---|---|---|

| Operation | Uses rapid switching to control power | Provides continuous voltage regulation |

| Efficiency | High efficiency, low power loss | Lower efficiency, higher power loss |

| Heat Generation | Minimal heat due to switching | Significant heat from continuous dissipation |

| Control Precision | Precise speed and torque control | Less precise compared to chopper drive |

| Applications | DC motor speed control, electric vehicles | Audio amplifiers, low-power motor control |

| Cost | Moderate cost, complex design | Simple design, generally lower cost |

Introduction to Chopper Drive and Linear Drive

Chopper Drive and Linear Drive represent two distinct methods of controlling electric motors, each optimizing performance in specific applications. Chopper Drive uses pulse-width modulation (PWM) to regulate voltage, enhancing efficiency in DC motor speed control by precisely adjusting current flow. Linear Drive provides smooth and continuous voltage adjustment, ideal for applications requiring minimal electrical noise and steady motor operation, ensuring your motor control matches exact performance needs.

Fundamental Principles: How Chopper Drives Work

Chopper drives regulate voltage by rapidly switching the supply on and off, controlling the average power delivered to the motor through pulse width modulation (PWM). This switching process adjusts the effective voltage and current, enabling efficient speed and torque control in DC motors. Unlike linear drives that vary resistance to control current, chopper drives minimize energy loss by operating in a switching mode, resulting in higher efficiency and reduced heat generation.

Linear Drive: Basic Operation and Mechanism

Linear drives operate by directly converting electrical energy into linear motion through electromagnetic forces, eliminating the need for mechanical components like gears or screws. This mechanism typically utilizes a magnetic field generated by a coil interacting with a permanent magnet or magnetic track, resulting in precise and smooth movement along a straight path. The absence of mechanical contact reduces wear and friction, enhancing efficiency and reliability in applications such as robotics, CNC machinery, and automated systems.

Key Differences Between Chopper and Linear Drives

Chopper drives regulate motor speed using pulse-width modulation, providing energy-efficient, quick torque control ideal for variable speed applications, while linear drives offer smooth, continuous voltage output suitable for precise, low-noise motor operation. Chopper drives typically handle higher power levels with better thermal management, whereas linear drives dissipate excess energy as heat, making them less efficient at high loads. Understanding these distinctions helps you select the optimal drive type for your specific motor control needs, balancing efficiency, complexity, and performance.

Efficiency and Power Consumption Comparison

Chopper Drive systems offer higher efficiency in variable load conditions by rapidly switching current through inductors, minimizing energy loss and reducing power consumption compared to Linear Drives, which operate continuously and dissipate more heat. Linear Drives provide smooth, precise control but are less efficient, often consuming more power due to constant voltage application and resistive losses. Your choice depends on prioritizing energy savings and efficiency with Chopper Drives or precision with Linear Drives.

Performance in Speed and Torque Control

Chopper drives offer efficient speed control by rapidly switching voltage, enabling precise torque regulation ideal for applications requiring quick acceleration and deceleration. Linear drives provide smooth and continuous torque output with minimal ripple, enhancing performance in systems demanding steady and silent operation. Your choice between chopper and linear drives should consider the specific speed and torque control requirements of your application for optimal efficiency and responsiveness.

Cost Implications and Maintenance Requirements

Chopper drives generally have lower initial costs due to simpler electronics and less complex control algorithms compared to linear drives, making them a cost-effective solution for many applications. Maintenance requirements for chopper drives tend to be higher because of mechanical wear and the need for periodic inspection of commutators and brushes in DC motors. Linear drives, while more expensive upfront due to advanced components like linear motors and sophisticated control systems, usually offer reduced maintenance needs because they eliminate mechanical contact and friction, resulting in longer service intervals and lower downtime.

Application Suitability: Where Each Drive Excels

Chopper drives excel in applications requiring precise speed control and high torque at low speeds, making them ideal for electric vehicles and robotics. Linear drives offer superior performance in positioning accuracy and smooth motion, which suits CNC machines, conveyors, and automation systems. Your choice depends on whether efficiency in speed control or precision in linear movement is the primary requirement.

Pros and Cons of Chopper Drive vs Linear Drive

Chopper drives offer high efficiency and precise speed control by rapidly switching power, making them ideal for variable speed applications, but they can generate electrical noise and require complex circuitry. Linear drives provide smooth, continuous power with minimal electrical noise and simple design, yet they suffer from lower efficiency and higher heat dissipation, limiting their use in high-power scenarios. Comparing both, chopper drives excel in energy-saving and dynamic performance, while linear drives are preferred for stable, noise-sensitive environments.

Conclusion: Choosing the Right Drive System

Chopper drives excel in energy efficiency and precise speed control for DC motors, making them ideal for battery-powered applications. Linear drives provide smooth, continuous operation with minimal noise and vibration, suited for high-precision positioning tasks. Selecting the right drive system depends on application requirements such as efficiency, noise levels, and control precision.

Chopper Drive vs Linear Drive Infographic

electrown.com

electrown.com