Diode bridges offer a simple and cost-effective way to convert AC to DC but tend to have higher power losses due to their fixed voltage drops. Understanding the advantages of active rectifiers, such as improved efficiency and reduced heat generation, can help optimize Your power conversion systems--read on to explore the detailed comparison.

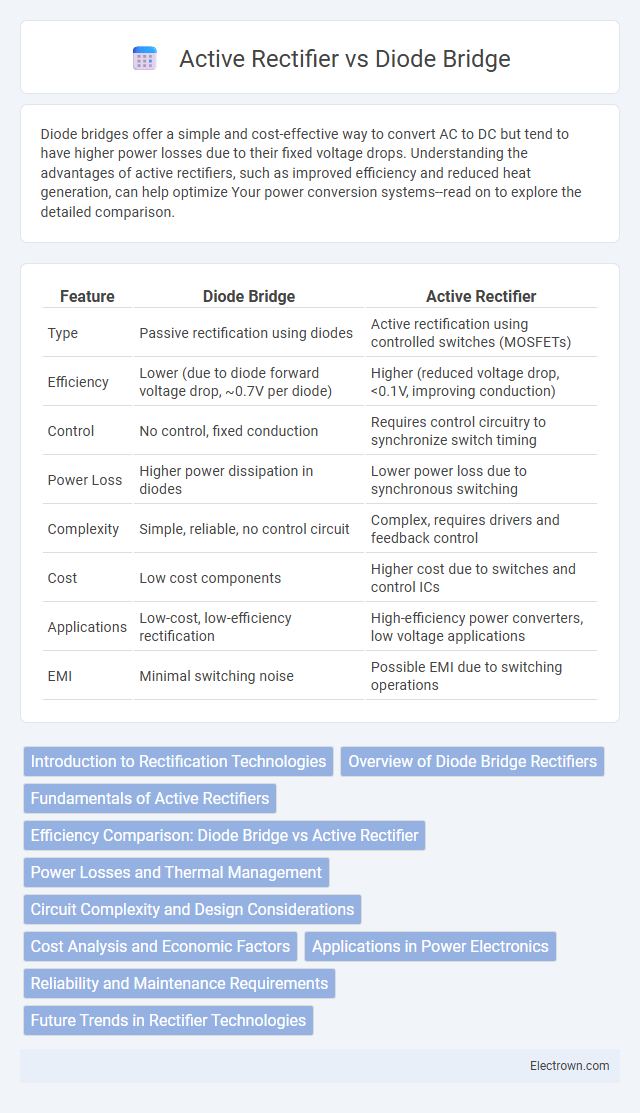

Table of Comparison

| Feature | Diode Bridge | Active Rectifier |

|---|---|---|

| Type | Passive rectification using diodes | Active rectification using controlled switches (MOSFETs) |

| Efficiency | Lower (due to diode forward voltage drop, ~0.7V per diode) | Higher (reduced voltage drop, <0.1V, improving conduction) |

| Control | No control, fixed conduction | Requires control circuitry to synchronize switch timing |

| Power Loss | Higher power dissipation in diodes | Lower power loss due to synchronous switching |

| Complexity | Simple, reliable, no control circuit | Complex, requires drivers and feedback control |

| Cost | Low cost components | Higher cost due to switches and control ICs |

| Applications | Low-cost, low-efficiency rectification | High-efficiency power converters, low voltage applications |

| EMI | Minimal switching noise | Possible EMI due to switching operations |

Introduction to Rectification Technologies

Diode bridges and active rectifiers are key technologies in converting alternating current (AC) to direct current (DC), essential for power supply units and renewable energy systems. Diode bridges utilize semiconductor diodes for passive rectification, offering simplicity and reliability but with inherent voltage drops and power losses. Active rectifiers employ controlled semiconductor switches like MOSFETs or IGBTs, enabling higher efficiency through synchronous rectification and precise control, making them preferable in high-performance and energy-sensitive applications.

Overview of Diode Bridge Rectifiers

Diode bridge rectifiers consist of four diodes arranged in a bridge configuration to convert alternating current (AC) into direct current (DC) efficiently. They offer a simple, reliable, and cost-effective solution for AC to DC conversion, widely used in power supplies and electronic devices. Despite inherent power losses due to diode forward voltage drops, diode bridges provide robust performance under various load conditions without active control circuitry.

Fundamentals of Active Rectifiers

Active rectifiers utilize controlled semiconductor switches, such as MOSFETs or IGBTs, to convert AC to DC with high efficiency and reduced voltage drop, unlike traditional diode bridges that rely on passive diodes. These devices enable bidirectional power flow and improved power factor correction by actively managing the switching intervals based on input voltage and current waveforms. The fundamental operation of active rectifiers involves continuous sensing and feedback control to minimize harmonic distortion and optimize energy conversion in diverse power electronics applications.

Efficiency Comparison: Diode Bridge vs Active Rectifier

Active rectifiers offer significantly higher efficiency than diode bridges by reducing conduction losses through controlled switching elements instead of fixed diodes. While diode bridges typically exhibit forward voltage drops around 0.7V per diode, resulting in power losses especially at low voltages, active rectifiers utilize MOSFETs with minimal resistance, achieving efficiencies exceeding 95%. This efficiency improvement in active rectifiers directly translates to reduced heat generation and enhanced performance in power conversion applications.

Power Losses and Thermal Management

Diode bridges experience higher power losses due to the forward voltage drop of each diode, leading to increased heat generation and requiring robust thermal management systems such as heat sinks or cooling fans. Active rectifiers use controlled switches like MOSFETs which significantly reduce conduction losses, improving efficiency and minimizing heat dissipation. Optimizing your power system with an active rectifier enhances thermal performance and reduces energy waste compared to traditional diode bridge rectifiers.

Circuit Complexity and Design Considerations

Diode bridges offer a simpler circuit design with fewer components, making them cost-effective and easy to implement for basic AC to DC conversion. Active rectifiers utilize MOSFETs or IGBTs with control circuitry, increasing circuit complexity but improving efficiency by reducing conduction losses. Design considerations for active rectifiers include gate driving, synchronization, and protection mechanisms, which demand precise control and increase overall design intricacy compared to passive diode bridges.

Cost Analysis and Economic Factors

A diode bridge offers a low-cost, reliable solution with minimal upfront investment and no need for complex control circuitry, making it economically favorable for simple AC to DC conversion. Active rectifiers, while more expensive due to advanced semiconductor components and control systems, provide higher efficiency and reduced power loss, resulting in long-term energy savings and improved performance in high-demand applications. Considering total cost of ownership, diode bridges suit budget-conscious projects, whereas active rectifiers justify their higher initial cost through operational cost reductions and enhanced energy efficiency.

Applications in Power Electronics

Diode bridges are widely used in power electronics for converting AC to DC in applications such as power supplies, battery chargers, and motor drives due to their simplicity and reliability. Active rectifiers, employing controlled switches like MOSFETs or IGBTs, offer higher efficiency and reduced harmonic distortion, making them ideal for applications requiring precise control and energy savings, such as renewable energy systems and electric vehicle chargers. Your choice between a diode bridge and an active rectifier depends on factors like efficiency requirements, cost constraints, and the specific power electronics application.

Reliability and Maintenance Requirements

Diode bridges offer high reliability with minimal maintenance due to their simple, robust design and absence of moving parts, making them suitable for long-term, low-maintenance applications. Active rectifiers, while more complex and requiring regular maintenance to ensure optimal performance, provide superior efficiency and dynamic control in power conversion systems. You should consider the trade-off between the low maintenance needs of diode bridges and the performance benefits of active rectifiers when selecting a rectification solution.

Future Trends in Rectifier Technologies

Future trends in rectifier technologies emphasize active rectifiers due to their higher efficiency, reduced power losses, and improved power factor correction compared to traditional diode bridges. Advances in wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are enabling active rectifiers to operate at higher frequencies and temperatures, enhancing performance in electric vehicles and renewable energy systems. Integration of smart control algorithms and real-time monitoring further drives the shift towards active rectifier designs in next-generation power electronics.

Diode Bridge vs Active Rectifier Infographic

electrown.com

electrown.com