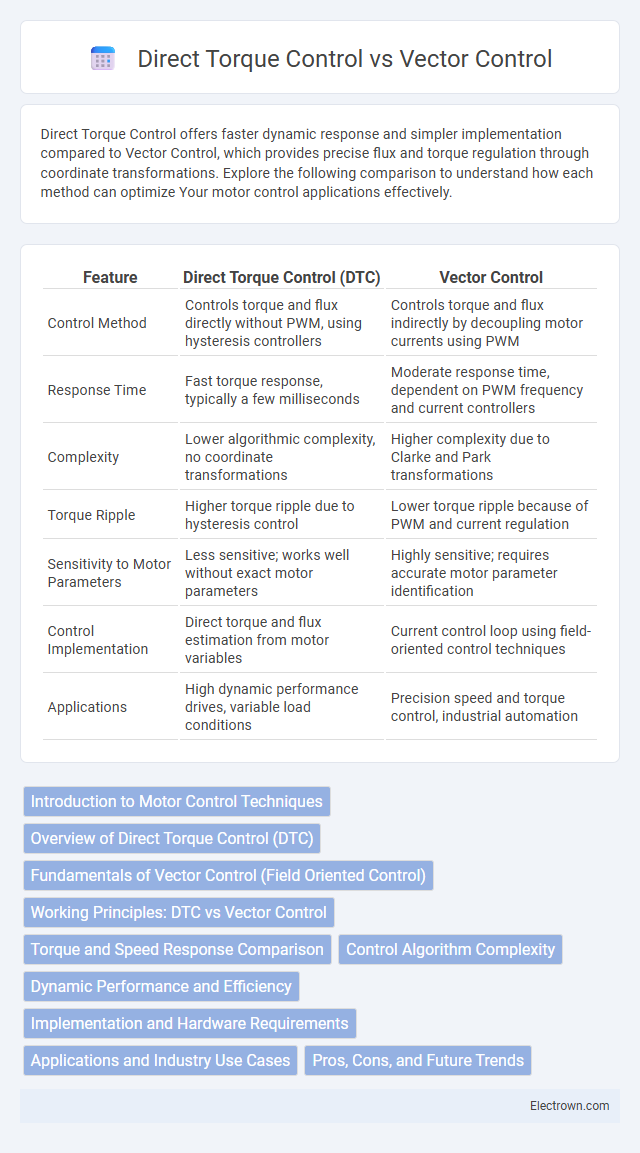

Direct Torque Control offers faster dynamic response and simpler implementation compared to Vector Control, which provides precise flux and torque regulation through coordinate transformations. Explore the following comparison to understand how each method can optimize Your motor control applications effectively.

Table of Comparison

| Feature | Direct Torque Control (DTC) | Vector Control |

|---|---|---|

| Control Method | Controls torque and flux directly without PWM, using hysteresis controllers | Controls torque and flux indirectly by decoupling motor currents using PWM |

| Response Time | Fast torque response, typically a few milliseconds | Moderate response time, dependent on PWM frequency and current controllers |

| Complexity | Lower algorithmic complexity, no coordinate transformations | Higher complexity due to Clarke and Park transformations |

| Torque Ripple | Higher torque ripple due to hysteresis control | Lower torque ripple because of PWM and current regulation |

| Sensitivity to Motor Parameters | Less sensitive; works well without exact motor parameters | Highly sensitive; requires accurate motor parameter identification |

| Control Implementation | Direct torque and flux estimation from motor variables | Current control loop using field-oriented control techniques |

| Applications | High dynamic performance drives, variable load conditions | Precision speed and torque control, industrial automation |

Introduction to Motor Control Techniques

Direct Torque Control (DTC) enables precise regulation of motor torque and flux by directly adjusting the stator flux vector, resulting in fast dynamic response and reduced parameter dependency. Vector Control, also known as Field-Oriented Control (FOC), transforms motor currents into orthogonal components to independently control torque and flux, achieving high performance in speed and torque regulation. Your choice between DTC and Vector Control impacts system complexity, efficiency, and response characteristics in motor control applications.

Overview of Direct Torque Control (DTC)

Direct Torque Control (DTC) is a high-performance method used in AC motor drives for precise torque and flux regulation without the need for complex coordinate transformations. It achieves rapid dynamic response by directly controlling the stator flux linkage and torque through switching state selection of the inverter. DTC offers enhanced robustness against parameter variations and reduced computational complexity compared to traditional Vector Control techniques.

Fundamentals of Vector Control (Field Oriented Control)

Vector Control, also known as Field Oriented Control (FOC), fundamentally focuses on decoupling the stator current into torque and flux components to independently control motor torque and magnetic flux. This method utilizes coordinate transformations, typically from a stationary to a rotating reference frame, enabling precise control of the motor's electromagnetic fields and improving dynamic performance. Your motor's efficiency and response times significantly benefit from the accurate and real-time adjustments provided by vector control techniques.

Working Principles: DTC vs Vector Control

Direct Torque Control (DTC) operates by directly regulating the motor's torque and flux through quick estimation and switching of inverter states, enabling fast dynamic response without the need for pulse width modulation. Vector Control, also known as Field-Oriented Control (FOC), separates the motor current into orthogonal components for flux and torque, using coordinate transformation and a PWM inverter to achieve precise torque control and smooth operation. While DTC offers simpler control with rapid torque response, Vector Control provides higher accuracy and better steady-state performance by controlling both magnitude and phase of the motor currents.

Torque and Speed Response Comparison

Direct Torque Control (DTC) provides faster torque and speed response due to its ability to directly regulate flux and torque without the need for coordinate transformations, enabling rapid dynamic performance. In contrast, Vector Control (Field-Oriented Control) achieves high precision in torque and speed by decoupling flux and torque components but typically exhibits slower response times due to complex modulation and control loops. DTC's direct switching approach results in quicker torque reaction, making it ideal for applications requiring rapid acceleration and deceleration, whereas Vector Control offers smoother operation with better steady-state accuracy.

Control Algorithm Complexity

Direct Torque Control (DTC) features a simpler control algorithm that directly regulates motor torque and flux without requiring coordinate transformations or pulse width modulation (PWM) modulators, resulting in faster dynamic response. Vector Control, also known as Field-Oriented Control (FOC), involves more complex algorithmic steps including rotor flux estimation, coordinate transformations between stationary and rotating reference frames, and sophisticated PI controllers to achieve precise torque and speed control. The increased complexity in Vector Control's control algorithm generally leads to higher computational demand compared to the more straightforward implementation of DTC.

Dynamic Performance and Efficiency

Direct Torque Control (DTC) offers superior dynamic performance with faster torque response and reduced ripple compared to Vector Control, making it ideal for high-precision applications. Vector Control provides higher efficiency at steady-state conditions due to its precise flux management and smooth current regulation. You benefit from choosing DTC when rapid torque changes are crucial, while Vector Control excels in consistent energy-efficient operation.

Implementation and Hardware Requirements

Direct Torque Control (DTC) features a simpler control algorithm with no need for coordinate transformations or pulse-width modulation, enabling faster torque response and robustness in implementation. In contrast, Vector Control requires complex mathematical transformations, such as Clarke and Park transforms, and precise modulation schemes, demanding more computational power and sophisticated microcontrollers. Hardware-wise, DTC can operate effectively with minimal sensors and simpler inverter circuits, whereas Vector Control often necessitates high-resolution encoders and advanced power electronics for accurate flux and torque regulation.

Applications and Industry Use Cases

Direct Torque Control (DTC) is widely used in industrial drives requiring fast dynamic response and precise torque control, such as electric vehicles, robotics, and high-performance manufacturing machinery. Vector Control finds extensive applications in HVAC systems, pumps, compressors, and crane operations where smooth speed regulation and energy efficiency are critical. Both methods enhance motor performance, but DTC excels in high-performance, torque-sensitive applications, while Vector Control dominates in steady-state, speed-regulated industrial processes.

Pros, Cons, and Future Trends

Direct Torque Control (DTC) offers fast dynamic response and simple implementation, making it highly efficient for applications requiring precise torque control without complex coordinate transformations. However, it may suffer from higher torque ripple and less smooth flux control compared to Vector Control, which ensures better steady-state performance and lower torque ripple through accurate field orientation and modulation. Future trends focus on integrating sensorless techniques and advanced algorithms like machine learning to enhance DTC's accuracy and reduce its torque ripple, while Vector Control advances toward real-time adaptive control to optimize energy efficiency and motor lifespan.

Direct Torque Control vs Vector Control Infographic

electrown.com

electrown.com