Mechanical interlocks physically prevent equipment operation until conditions are met, ensuring safety through tangible barriers, while electrical interlocks use control circuits to disable machinery until specific signals confirm safe operation. Understanding the distinct functions of mechanical and electrical interlocks can help You choose the right safety mechanism for your application--explore the full article to learn more.

Table of Comparison

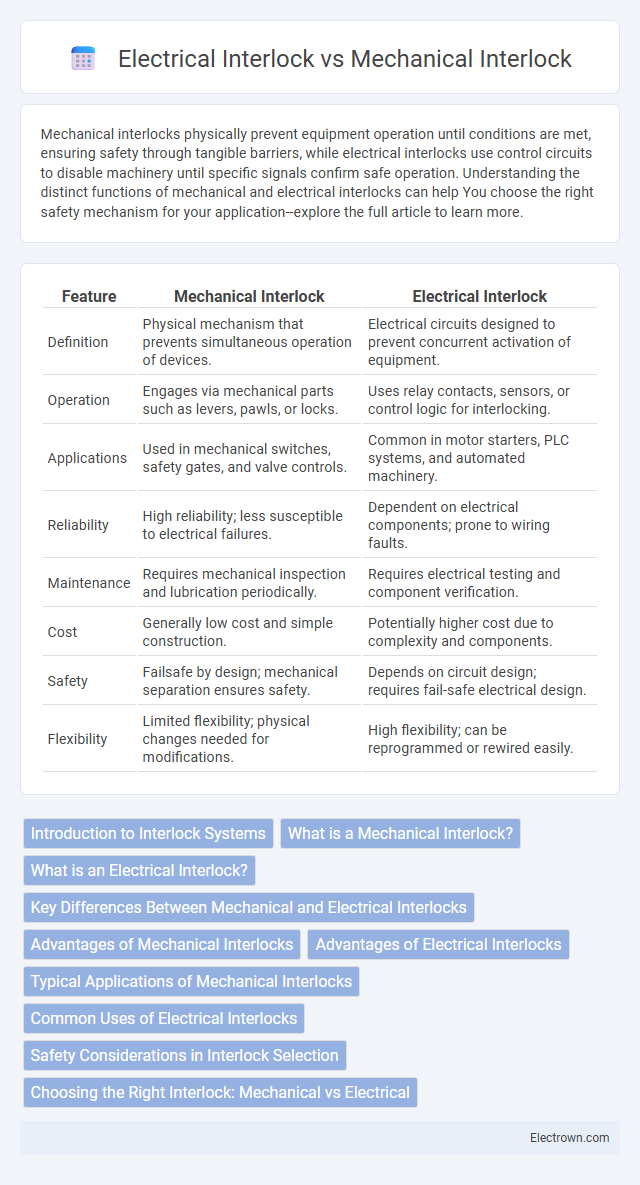

| Feature | Mechanical Interlock | Electrical Interlock |

|---|---|---|

| Definition | Physical mechanism that prevents simultaneous operation of devices. | Electrical circuits designed to prevent concurrent activation of equipment. |

| Operation | Engages via mechanical parts such as levers, pawls, or locks. | Uses relay contacts, sensors, or control logic for interlocking. |

| Applications | Used in mechanical switches, safety gates, and valve controls. | Common in motor starters, PLC systems, and automated machinery. |

| Reliability | High reliability; less susceptible to electrical failures. | Dependent on electrical components; prone to wiring faults. |

| Maintenance | Requires mechanical inspection and lubrication periodically. | Requires electrical testing and component verification. |

| Cost | Generally low cost and simple construction. | Potentially higher cost due to complexity and components. |

| Safety | Failsafe by design; mechanical separation ensures safety. | Depends on circuit design; requires fail-safe electrical design. |

| Flexibility | Limited flexibility; physical changes needed for modifications. | High flexibility; can be reprogrammed or rewired easily. |

Introduction to Interlock Systems

Mechanical interlock systems use physical barriers to prevent simultaneous operation of conflicting components, ensuring safety by physically restricting movement. Electrical interlock systems rely on circuitry and sensors to control equipment activation, preventing hazardous conditions through automated electrical control. Understanding the differences helps you choose the appropriate interlock system for reliable and safe machinery operation.

What is a Mechanical Interlock?

A mechanical interlock is a physical safety device designed to prevent two or more actions from occurring simultaneously by using gears, bars, or locks that physically restrict movement. Commonly used in industrial equipment and electrical switchgear, it ensures that machinery or circuit breakers cannot be operated in unsafe sequences, thereby preventing mechanical damage or electrical hazards. This physical barrier effectively enforces operational safety protocols without relying on electrical signals or sensors.

What is an Electrical Interlock?

An electrical interlock is a safety mechanism designed to prevent equipment from operating under unsafe conditions by controlling electrical circuits. It uses electrical signals to ensure that certain conditions are met before power is supplied or machinery is activated, minimizing risks of damage or injury. Your system's reliability increases with electrical interlocks, as they provide automated control and enhanced protection compared to mechanical interlocks.

Key Differences Between Mechanical and Electrical Interlocks

Mechanical interlocks rely on physical components like levers or gears to prevent simultaneous operation of hazardous equipment, ensuring safety through direct physical intervention. Electrical interlocks use sensor signals, relays, or control circuits to monitor and inhibit equipment operation, allowing more flexible and remote-controlled safety mechanisms. Mechanical interlocks provide fail-safe operation in case of power loss, while electrical interlocks offer integration with automated systems for enhanced control and diagnostics.

Advantages of Mechanical Interlocks

Mechanical interlocks provide robust physical separation to prevent unintended operation of machinery, enhancing safety by eliminating reliance on electrical signals alone. They offer greater reliability in harsh environments where electrical components may fail due to moisture, dust, or vibrations. Your system benefits from simpler installation and maintenance, reducing downtime and costs compared to electrical interlocks.

Advantages of Electrical Interlocks

Electrical interlocks offer faster response times and higher precision in controlling machinery compared to mechanical interlocks. Their integration with digital control systems enables automated safety protocols and remote monitoring capabilities. Enhanced durability and reduced wear make electrical interlocks more reliable in high-cycle or harsh industrial environments.

Typical Applications of Mechanical Interlocks

Mechanical interlocks are commonly used in industrial machinery and electrical switchgear to physically prevent unsafe operation sequences, ensuring operator safety and equipment protection. Typical applications include locking access doors on hazardous equipment until power is safely disconnected and coordinating the operation of circuit breakers or disconnect switches to avoid simultaneous closure. Your systems benefit from mechanical interlocks by providing reliable, fail-safe constraints that reduce the risk of accidents and equipment damage.

Common Uses of Electrical Interlocks

Electrical interlocks are commonly used in industrial machinery to prevent dangerous simultaneous operation of equipment, such as ensuring a motor cannot start if a guard door is open. They are integral in control systems for safety circuits, often found in conveyor systems, manufacturing lines, and electrical panels to minimize the risk of operator injury or equipment damage. These interlocks rely on electrical signals and sensors to enable or disable machine functions based on predefined safety conditions.

Safety Considerations in Interlock Selection

Mechanical interlocks provide robust physical barriers that prevent machinery operation unless specific conditions are met, significantly reducing the risk of accidental startup and enhancing operator safety. Electrical interlocks use circuits to control equipment functions, allowing for more complex safety logic but requiring regular inspection to prevent failures due to wiring issues or electrical faults. Selecting between mechanical and electrical interlocks should prioritize the environment, application risk level, and maintenance capabilities to ensure optimal protection against unintended equipment activation and ensure compliance with safety standards.

Choosing the Right Interlock: Mechanical vs Electrical

Choosing the right interlock depends on your application's safety, reliability, and environmental conditions. Mechanical interlocks offer robust physical barriers and are ideal for harsh environments with minimal maintenance, while electrical interlocks provide faster response times and integration with automated control systems. Evaluating your operational demands and safety requirements ensures optimal protection and efficient system performance.

Mechanical Interlock vs Electrical Interlock Infographic

electrown.com

electrown.com