Machine vision systems provide advanced image processing capabilities to analyze products, detect defects, and guide robotic systems, whereas barcode readers specialize in quickly capturing and decoding barcodes for inventory and tracking purposes. Explore the rest of the article to discover which technology suits your operational needs best.

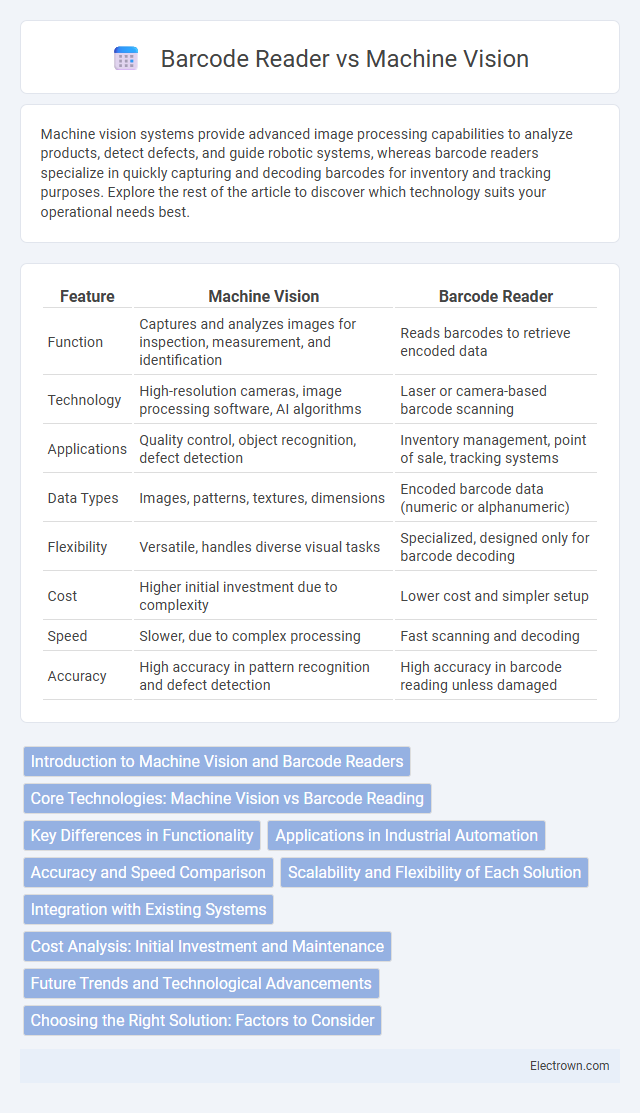

Table of Comparison

| Feature | Machine Vision | Barcode Reader |

|---|---|---|

| Function | Captures and analyzes images for inspection, measurement, and identification | Reads barcodes to retrieve encoded data |

| Technology | High-resolution cameras, image processing software, AI algorithms | Laser or camera-based barcode scanning |

| Applications | Quality control, object recognition, defect detection | Inventory management, point of sale, tracking systems |

| Data Types | Images, patterns, textures, dimensions | Encoded barcode data (numeric or alphanumeric) |

| Flexibility | Versatile, handles diverse visual tasks | Specialized, designed only for barcode decoding |

| Cost | Higher initial investment due to complexity | Lower cost and simpler setup |

| Speed | Slower, due to complex processing | Fast scanning and decoding |

| Accuracy | High accuracy in pattern recognition and defect detection | High accuracy in barcode reading unless damaged |

Introduction to Machine Vision and Barcode Readers

Machine vision systems use advanced cameras and image processing software to capture and analyze visual data for automated inspection, measurement, and guidance tasks, enabling higher accuracy and flexibility in industrial applications. Barcode readers rely on laser or camera technology to quickly scan and decode barcodes, providing efficient data capture for inventory management and retail operations. Both technologies enhance automation but serve distinct purposes: machine vision interprets complex visual information, while barcode readers focus on fast, reliable product identification.

Core Technologies: Machine Vision vs Barcode Reading

Machine vision systems utilize advanced image processing algorithms and high-resolution cameras to analyze visual data, enabling them to inspect, measure, and identify complex objects or patterns beyond simple code recognition. Barcode readers rely on laser or LED light to scan standardized linear or 2D barcodes, decoding numerical or alphanumeric information quickly and efficiently. Your choice depends on whether you require detailed visual inspections or straightforward product identification through barcode scanning.

Key Differences in Functionality

Machine vision systems utilize advanced cameras and image processing algorithms to interpret complex visual data, enabling tasks like object recognition and quality inspection. Barcode readers specifically focus on scanning and decoding barcode patterns for product identification and inventory management. Unlike barcode readers, machine vision offers broader functionality by analyzing shape, color, and texture beyond simple code reading.

Applications in Industrial Automation

Machine vision systems enable complex inspection, measurement, and guidance tasks in industrial automation by capturing and analyzing detailed images, while barcode readers provide fast and reliable identification and tracking of products through barcode decoding. Your production line benefits from machine vision's ability to handle varied tasks such as quality control, defect detection, and robotic guidance, whereas barcode readers excel in inventory management and point-of-sale applications. Integrating both technologies enhances efficiency, accuracy, and traceability within automated manufacturing environments.

Accuracy and Speed Comparison

Machine vision systems deliver higher accuracy by capturing detailed images and analyzing complex patterns, reducing errors in object recognition compared to barcode readers. Barcode readers offer faster scanning speeds for simple, linear data but may struggle with damaged or poorly printed codes, impacting reliability. In industrial applications, machine vision outperforms barcode readers in speed when processing varied or complex tasks, ensuring greater precision and operational efficiency.

Scalability and Flexibility of Each Solution

Machine vision systems offer higher scalability by enabling complex image analysis and adaptability to diverse applications beyond simple barcode decoding, supporting multiple data types and custom algorithms. Barcode readers provide a cost-effective, plug-and-play solution optimized for high-speed, repetitive scanning tasks but lack flexibility when rapid changes or varied data recognition are required. Industrial environments benefit from machine vision's flexibility for evolving workflows, whereas barcode readers excel in standardized, high-volume operations.

Integration with Existing Systems

Machine vision systems offer seamless integration with existing manufacturing and quality control systems through advanced software compatibility and customizable APIs, enabling real-time data processing and analytics. Barcode readers, while simpler to install, typically require standard interfaces and may face limitations in handling complex production environments or multi-dimensional data capture. Industrial automation platforms benefit from machine vision's adaptability, supporting enhanced operational efficiency and scalability compared to traditional barcode scanning technologies.

Cost Analysis: Initial Investment and Maintenance

Machine vision systems typically require a higher initial investment than barcode readers due to advanced cameras, lighting, and processing hardware. Maintenance costs for machine vision involve regular calibration and software updates, which can be more expensive compared to the simpler sensor and scanner upkeep of barcode readers. Barcode readers offer a cost-effective solution with lower upfront expenses and minimal maintenance, making them suitable for basic scanning applications.

Future Trends and Technological Advancements

Machine vision systems are evolving with advancements in artificial intelligence, deep learning, and high-resolution imaging, enabling more accurate object recognition and complex inspection beyond traditional barcode reading. Barcode readers continue to improve with enhanced scanning speeds, longer-range capabilities, and integration with IoT devices for real-time inventory management. Future trends indicate a convergence where hybrid systems leverage both technologies to optimize automation, quality control, and data collection in manufacturing and retail sectors.

Choosing the Right Solution: Factors to Consider

Selecting between machine vision and barcode readers depends on factors such as application complexity, speed requirements, and environmental conditions. Machine vision systems excel in tasks requiring detailed inspection, object recognition, and flexibility, while barcode readers are optimal for straightforward, high-speed barcode scanning. Consider the cost, maintenance needs, and integration complexity to determine the best fit for specific operational goals.

Machine Vision vs Barcode Reader Infographic

electrown.com

electrown.com