Star Delta Starter reduces the initial starting current by switching the motor windings from a star to a delta configuration, making it ideal for standard motor startups with moderate load requirements. Understanding the operational differences and advantages of Auto Transformer Starters can help you choose the best method for smoother motor acceleration and better voltage control; read on to explore which starter suits your application perfectly.

Table of Comparison

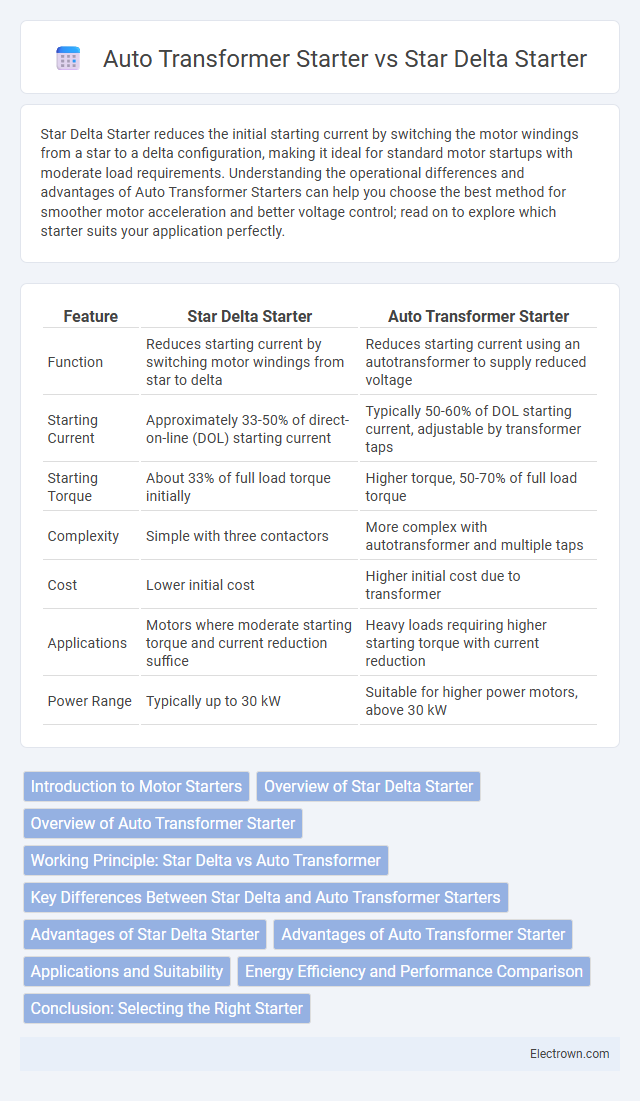

| Feature | Star Delta Starter | Auto Transformer Starter |

|---|---|---|

| Function | Reduces starting current by switching motor windings from star to delta | Reduces starting current using an autotransformer to supply reduced voltage |

| Starting Current | Approximately 33-50% of direct-on-line (DOL) starting current | Typically 50-60% of DOL starting current, adjustable by transformer taps |

| Starting Torque | About 33% of full load torque initially | Higher torque, 50-70% of full load torque |

| Complexity | Simple with three contactors | More complex with autotransformer and multiple taps |

| Cost | Lower initial cost | Higher initial cost due to transformer |

| Applications | Motors where moderate starting torque and current reduction suffice | Heavy loads requiring higher starting torque with current reduction |

| Power Range | Typically up to 30 kW | Suitable for higher power motors, above 30 kW |

Introduction to Motor Starters

Star Delta Starter and Auto Transformer Starter are two common motor starting methods used to reduce inrush current and mechanical stress during motor startup. Star Delta Starters initially connect the motor windings in a star configuration for reduced voltage starting before switching to a delta connection for full voltage operation, ideal for squirrel cage induction motors. Auto Transformer Starters employ an auto transformer to supply reduced voltage during startup, offering adjustable voltage levels and better control over starting torque and current.

Overview of Star Delta Starter

Star Delta Starter is an electrical motor starter used to reduce the starting current and limit the initial surge of AC motors by initially connecting the motor windings in a star (Y) configuration, then switching to a delta (D) configuration for normal operation. This method effectively lowers the voltage applied to each winding during startup to approximately 58% of the line voltage, reducing mechanical stress and electrical peaks. Star Delta Starters are widely used for motors rated up to 15 kW where cost-effective and simpler starting solutions are suitable compared to Auto Transformer Starters.

Overview of Auto Transformer Starter

The Auto Transformer Starter reduces voltage during motor startup by using an autotransformer to limit inrush current and torque, enhancing motor protection and energy efficiency. It allows adjustable voltage taps, enabling smoother acceleration compared to direct-on-line starters. Your motor benefits from reduced mechanical stress and improved starting performance, making it ideal for medium to large induction motors with high starting torque requirements.

Working Principle: Star Delta vs Auto Transformer

The Star Delta Starter operates by initially connecting the motor windings in a star configuration to reduce voltage and current during startup, then switches to a delta configuration for normal running to provide full voltage. The Auto Transformer Starter utilizes a tapped auto transformer to supply reduced voltage to the motor during startup, gradually increasing it to full voltage as the motor accelerates. Both methods aim to limit inrush current and reduce mechanical stress but achieve this through different electrical configurations and voltage reduction techniques.

Key Differences Between Star Delta and Auto Transformer Starters

Star Delta Starter reduces the initial current by switching from star to delta configuration during motor startup, making it suitable for standard low-voltage motors with moderate starting torque requirements. Auto Transformer Starter provides adjustable voltage during startup through tapping, offering smoother acceleration and higher starting torque compared to star delta starters. Your choice depends on the motor's starting torque needs and application, with auto transformer starters favored for heavy-duty or high-torque requirements.

Advantages of Star Delta Starter

Star Delta Starters reduce the initial starting current to one-third compared to direct-on-line starters, minimizing electrical stress and enhancing motor lifespan. They provide cost-effective soft starting by switching the motor from star to delta configuration, optimizing energy use during startup. Your industrial motor benefits from smoother acceleration and reduced mechanical wear, improving overall operational efficiency.

Advantages of Auto Transformer Starter

Auto Transformer Starters provide reduced voltage starting, minimizing inrush current and mechanical stress on motors compared to direct-on-line or star-delta starters. They offer better control of the starting torque, enhancing motor lifespan and enabling smooth acceleration for heavy-duty applications. This method also improves energy efficiency during startup and allows adjustable voltage selection to match specific motor requirements.

Applications and Suitability

Star Delta Starters are ideal for starting squirrel cage induction motors with moderate starting torque requirements, commonly used in pumps, compressors, and fans to reduce initial current surge. Auto Transformer Starters provide higher starting torque and are suitable for heavier loads like crushers, crushers, and mills where smooth acceleration is critical. Your choice depends on the motor's load characteristics and the need for reduced voltage starting to protect electrical infrastructure.

Energy Efficiency and Performance Comparison

Star Delta Starters provide reliable motor starting with moderate energy savings by reducing voltage during startup, which limits inrush current and mechanical stress. Auto Transformer Starters enhance energy efficiency further by offering adjustable voltage settings, allowing smoother acceleration and reduced energy consumption in high-load applications. Your choice depends on the specific motor load requirements and the desired balance between performance optimization and energy-saving goals.

Conclusion: Selecting the Right Starter

Choosing between a Star Delta Starter and an Auto Transformer Starter depends on the motor's power rating and application requirements. Star Delta Starters are ideal for reducing starting current in motors typically between 5 to 20 HP, offering simplicity and cost-effectiveness. Auto Transformer Starters suit higher power motors above 20 HP, providing better voltage control and smoother acceleration for industrial heavy-duty operations.

Star Delta Starter vs Auto Transformer Starter Infographic

electrown.com

electrown.com