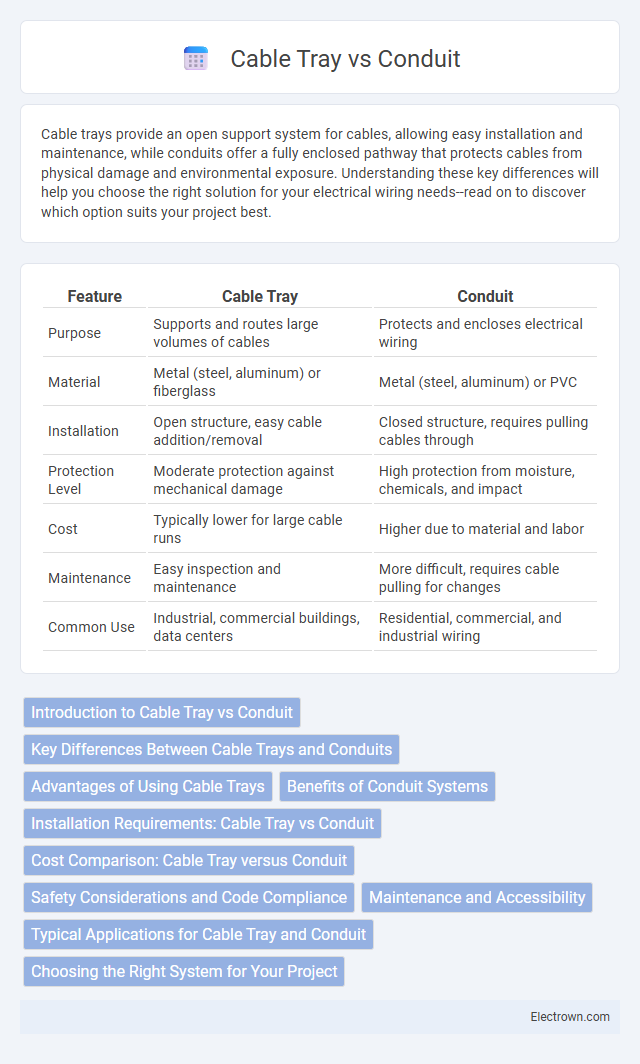

Cable trays provide an open support system for cables, allowing easy installation and maintenance, while conduits offer a fully enclosed pathway that protects cables from physical damage and environmental exposure. Understanding these key differences will help you choose the right solution for your electrical wiring needs--read on to discover which option suits your project best.

Table of Comparison

| Feature | Cable Tray | Conduit |

|---|---|---|

| Purpose | Supports and routes large volumes of cables | Protects and encloses electrical wiring |

| Material | Metal (steel, aluminum) or fiberglass | Metal (steel, aluminum) or PVC |

| Installation | Open structure, easy cable addition/removal | Closed structure, requires pulling cables through |

| Protection Level | Moderate protection against mechanical damage | High protection from moisture, chemicals, and impact |

| Cost | Typically lower for large cable runs | Higher due to material and labor |

| Maintenance | Easy inspection and maintenance | More difficult, requires cable pulling for changes |

| Common Use | Industrial, commercial buildings, data centers | Residential, commercial, and industrial wiring |

Introduction to Cable Tray vs Conduit

Cable trays and conduits serve as two primary methods for routing and protecting electrical wiring in commercial and industrial installations. Cable trays offer an open support system ideal for easy cable management, ventilation, and scalability, whereas conduits are enclosed systems providing robust protection against physical damage and environmental factors. Selecting between cable trays and conduits depends on factors such as project complexity, environmental exposure, installation flexibility, and maintenance requirements.

Key Differences Between Cable Trays and Conduits

Cable trays provide an open support system for electrical cables, allowing easy access for maintenance and heat dissipation, while conduits are enclosed tubes that protect cables from physical damage and environmental factors. Cable trays are preferred for large cable runs and flexible wiring modifications, whereas conduits offer superior protection in hazardous or outdoor environments. The choice between cable trays and conduits depends on factors like installation complexity, cost, accessibility, and the specific needs of the electrical system.

Advantages of Using Cable Trays

Cable trays offer superior ease of installation and maintenance compared to conduits, allowing for straightforward cable management and quick access for inspections or repairs. They provide excellent ventilation, reducing heat buildup and extending the lifespan of electrical cables. Cable trays also support greater flexibility in system expansion, accommodating large volumes of cables with minimal structural modifications.

Benefits of Conduit Systems

Conduit systems offer superior protection for electrical wiring against physical damage, moisture, and corrosive elements, ensuring longevity and safety in harsh environments. Their rigid structure facilitates organized wire management and easy inspection, reducing maintenance efforts and downtime. Conduit systems also provide enhanced grounding capabilities and compliance with stringent electrical codes, making them ideal for industrial and commercial installations.

Installation Requirements: Cable Tray vs Conduit

Cable tray installation requires open support systems that allow easy access for cable laying and future maintenance, typically mounted on walls, ceilings, or under floors following structural load guidelines and clearance standards such as NEC or IEC. Conduit installation demands a closed, rigid or flexible tubing system with precise bending and threading, requiring sealed fittings to protect cables from physical damage, moisture, and electromagnetic interference, often necessitating conduit fill calculations and grounding compliance. Both systems must adhere to local electrical codes and standards like NFPA 70 to ensure safety, durability, and operational efficiency in industrial or commercial environments.

Cost Comparison: Cable Tray versus Conduit

Cable trays generally offer a more cost-effective solution compared to conduit due to lower material and labor expenses, especially in large-scale electrical installations. Installation costs for cable trays are reduced because they allow for easier cable routing and modifications without extensive dismantling, unlike conduits that require precise bending and fitting. Maintenance and future expansion are also more affordable with cable trays, making them a preferred choice in commercial and industrial projects seeking budget efficiency.

Safety Considerations and Code Compliance

Cable trays offer superior safety by providing organized cable management that reduces overheating risks and facilitates easier inspection compared to conduits, which may trap heat and complicate maintenance. Compliance with NEC (National Electrical Code) Article 392 mandates proper installation of cable trays to prevent physical damage and ensure grounding, while conduit installations must follow NEC Article 358 or 352 for electrical metallic tubing (EMT) and rigid nonmetallic conduit, emphasizing secure joints and support. Choosing between cable trays and conduits depends on project-specific safety requirements, environmental conditions, and adherence to local electrical codes for optimal protection and compliance.

Maintenance and Accessibility

Cable trays offer superior maintenance and accessibility by allowing easy visual inspection, cable addition, or removal without extensive disruption. Conduits require more effort for maintenance since cables are enclosed, often necessitating pulling or fish tape during installation or repair. The open design of cable trays reduces downtime and labor costs compared to conduit systems where access is limited.

Typical Applications for Cable Tray and Conduit

Cable trays are commonly used in industrial and commercial buildings for routing large volumes of power, data, and communication cables, particularly in areas requiring frequent cable modifications or expansions. Conduits provide superior mechanical protection, making them ideal for environments with exposure to moisture, chemicals, or physical damage, such as outdoor installations and harsh industrial sites. Choosing between cable tray and conduit depends on your project's specific needs for accessibility, protection, and cable capacity.

Choosing the Right System for Your Project

Selecting between cable trays and conduits depends on project scale, installation environment, and maintenance needs. Cable trays provide better ventilation and easier access for cable management in large-scale industrial or commercial applications, while conduits offer superior protection against moisture, chemicals, and physical damage, ideal for outdoor or harsh environments. Evaluating factors such as installation cost, future expansion, and compliance with electrical codes ensures the optimal choice for safety and efficiency.

Cable Tray vs Conduit Infographic

electrown.com

electrown.com