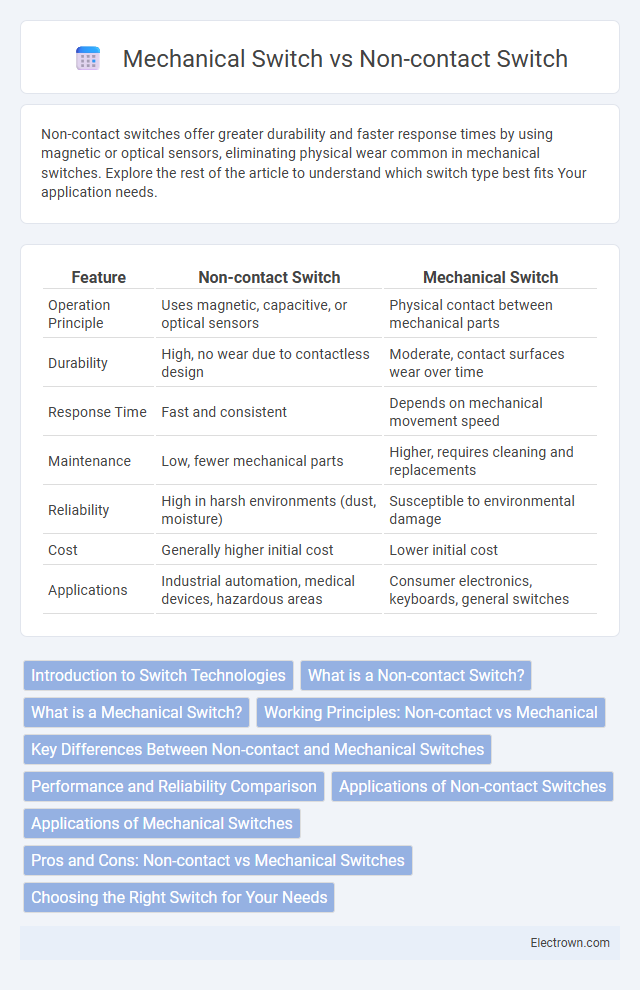

Non-contact switches offer greater durability and faster response times by using magnetic or optical sensors, eliminating physical wear common in mechanical switches. Explore the rest of the article to understand which switch type best fits Your application needs.

Table of Comparison

| Feature | Non-contact Switch | Mechanical Switch |

|---|---|---|

| Operation Principle | Uses magnetic, capacitive, or optical sensors | Physical contact between mechanical parts |

| Durability | High, no wear due to contactless design | Moderate, contact surfaces wear over time |

| Response Time | Fast and consistent | Depends on mechanical movement speed |

| Maintenance | Low, fewer mechanical parts | Higher, requires cleaning and replacements |

| Reliability | High in harsh environments (dust, moisture) | Susceptible to environmental damage |

| Cost | Generally higher initial cost | Lower initial cost |

| Applications | Industrial automation, medical devices, hazardous areas | Consumer electronics, keyboards, general switches |

Introduction to Switch Technologies

Non-contact switches utilize magnetic fields, capacitive sensing, or optical methods to register input without physical movement, offering higher durability and reduced wear compared to mechanical switches. Mechanical switches rely on physical contact between conductive elements to complete circuits, providing tactile feedback favored in gaming keyboards and industrial controls. Advances in non-contact switch technologies improve reliability and lifespan, making them ideal for environments requiring precise, maintenance-free operation.

What is a Non-contact Switch?

A non-contact switch is an electronic switch that operates without physical touch by detecting electromagnetic fields, proximity, or capacitive changes. It relies on sensors such as infrared, capacitive, or inductive types to trigger an electrical signal, ensuring durability and resistance to wear compared to mechanical switches. Non-contact switches are widely used in environments requiring hygiene, waterproofing, and long-term reliability, such as medical devices and industrial automation.

What is a Mechanical Switch?

A mechanical switch utilizes physical contacts that open or close a circuit when pressed, providing tactile feedback and reliable electrical connectivity. These switches often feature metal contacts that can wear over time, leading to potential degradation or failure. Understanding the characteristics of a mechanical switch helps you choose the right type for applications requiring durability and precise control.

Working Principles: Non-contact vs Mechanical

Non-contact switches operate using magnetic, capacitive, or optical sensors to detect the presence or movement without physical touch, ensuring minimal wear and longer lifespan. Mechanical switches rely on physical contact between moving parts, such as metal contacts closing a circuit, which can lead to mechanical degradation over time. Understanding the difference in working principles helps you select the ideal switch type for durability and performance in your application.

Key Differences Between Non-contact and Mechanical Switches

Non-contact switches utilize magnetic, capacitive, or optical sensing technologies to detect activation without physical movement, resulting in longer durability and reduced wear compared to mechanical switches that rely on physical contact for operation. Mechanical switches are prone to mechanical fatigue and contact degradation due to repeated physical actuation, whereas non-contact switches offer higher reliability and longer service life in harsh environments. The key differences include operational mechanism, lifespan, maintenance needs, and susceptibility to environmental factors such as dust and moisture.

Performance and Reliability Comparison

Non-contact switches use magnetic or optical sensors, eliminating physical wear and providing higher durability and consistent performance over millions of cycles. Mechanical switches rely on physical contact, which can degrade over time due to friction and oxidation, potentially leading to signal inconsistencies and failure. Your choice of switch directly impacts long-term reliability and maintenance needs, with non-contact options typically offering superior stability and longevity.

Applications of Non-contact Switches

Non-contact switches are widely used in environments requiring high reliability and durability, such as industrial automation, medical devices, and consumer electronics, where contamination and wear are concerns. They operate through proximity sensing technologies like capacitive, inductive, or optical methods, making them ideal for applications needing sealed or hygienic interfaces. Your choice of a non-contact switch enhances system longevity and reduces maintenance needs, especially in harsh or sterile conditions.

Applications of Mechanical Switches

Mechanical switches are widely used in industrial machinery, automotive controls, and household appliances due to their reliable tactile feedback and durability. They are ideal for environments requiring precise manual input, such as keyboards, control panels, and elevator buttons. Your choice of mechanical switches ensures consistent performance in demanding applications where physical actuation is necessary.

Pros and Cons: Non-contact vs Mechanical Switches

Non-contact switches, utilizing technologies like capacitive or optical sensing, offer prolonged durability and reduced wear due to the absence of physical contact, resulting in higher reliability and lower maintenance costs compared to mechanical switches. Mechanical switches provide tactile feedback and are often preferred for applications requiring precise user input, but they suffer from mechanical wear, shorter lifespan, and increased susceptibility to dust and debris. While non-contact switches excel in harsh environments and high-cycle applications, mechanical switches remain favored for their cost-effectiveness and familiar tactile response.

Choosing the Right Switch for Your Needs

Non-contact switches, using magnetic or capacitive sensing, offer higher durability and reliability with minimal wear over time, making them ideal for environments demanding longevity and low maintenance. Mechanical switches provide tactile feedback and are often preferred for applications requiring precise control and physical confirmation of activation. Consider your specific use case, environmental conditions, and desired user experience to select the best switch type for your needs.

Non-contact Switch vs Mechanical Switch Infographic

electrown.com

electrown.com