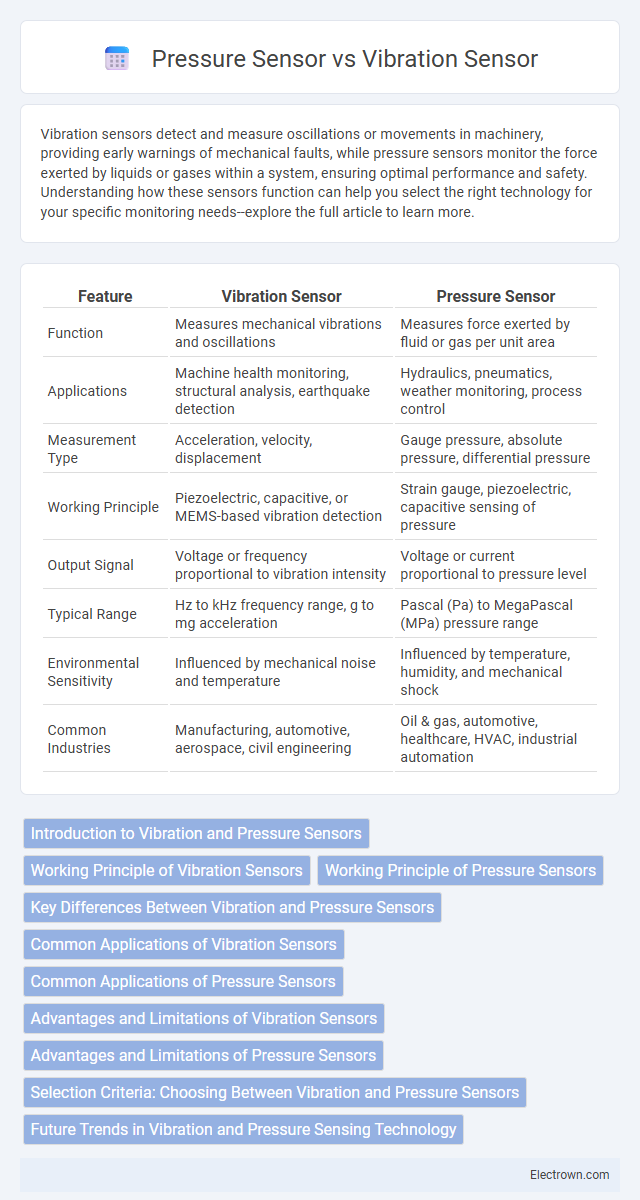

Vibration sensors detect and measure oscillations or movements in machinery, providing early warnings of mechanical faults, while pressure sensors monitor the force exerted by liquids or gases within a system, ensuring optimal performance and safety. Understanding how these sensors function can help you select the right technology for your specific monitoring needs--explore the full article to learn more.

Table of Comparison

| Feature | Vibration Sensor | Pressure Sensor |

|---|---|---|

| Function | Measures mechanical vibrations and oscillations | Measures force exerted by fluid or gas per unit area |

| Applications | Machine health monitoring, structural analysis, earthquake detection | Hydraulics, pneumatics, weather monitoring, process control |

| Measurement Type | Acceleration, velocity, displacement | Gauge pressure, absolute pressure, differential pressure |

| Working Principle | Piezoelectric, capacitive, or MEMS-based vibration detection | Strain gauge, piezoelectric, capacitive sensing of pressure |

| Output Signal | Voltage or frequency proportional to vibration intensity | Voltage or current proportional to pressure level |

| Typical Range | Hz to kHz frequency range, g to mg acceleration | Pascal (Pa) to MegaPascal (MPa) pressure range |

| Environmental Sensitivity | Influenced by mechanical noise and temperature | Influenced by temperature, humidity, and mechanical shock |

| Common Industries | Manufacturing, automotive, aerospace, civil engineering | Oil & gas, automotive, healthcare, HVAC, industrial automation |

Introduction to Vibration and Pressure Sensors

Vibration sensors detect mechanical oscillations and convert them into electrical signals to monitor equipment health, while pressure sensors measure the force exerted by fluids or gases on surfaces. Both sensors provide critical data for industrial automation, but vibration sensors primarily identify imbalances and faults in rotating machinery, whereas pressure sensors monitor system integrity and fluid dynamics. Your choice depends on the specific parameters needed for effective condition monitoring and process control.

Working Principle of Vibration Sensors

Vibration sensors detect mechanical oscillations by converting physical movement into electrical signals, often using piezoelectric, capacitive, or MEMS technology to sense changes in acceleration or displacement. These sensors respond to the amplitude, frequency, and velocity of vibrations, providing critical data for monitoring equipment health and predicting failures. Understanding the working principle of vibration sensors helps optimize your maintenance strategy by accurately identifying abnormal machine behavior.

Working Principle of Pressure Sensors

Pressure sensors operate by detecting the force exerted by a fluid or gas on a sensing element, typically using piezoelectric, capacitive, or strain gauge technologies to convert this physical pressure into an electrical signal. These sensors measure the deformation or change in electrical properties caused by pressure, enabling precise monitoring in applications such as HVAC systems, industrial process control, and automotive systems. Your choice between vibration sensors and pressure sensors should consider that pressure sensors specifically focus on static or dynamic pressure measurement, while vibration sensors detect oscillatory motion.

Key Differences Between Vibration and Pressure Sensors

Vibration sensors detect mechanical oscillations or movements by measuring changes in acceleration, velocity, or displacement, often used for monitoring rotating machinery or structural health. Pressure sensors measure the force exerted by liquids or gases on a surface, converting it into an electrical signal for applications in hydraulic systems, weather instruments, and process control. The key differences lie in their sensing principles: vibration sensors capture dynamic mechanical motion, while pressure sensors monitor static or dynamic fluid pressures.

Common Applications of Vibration Sensors

Vibration sensors are widely used in industrial machinery monitoring, predictive maintenance, and fault detection to identify imbalances, misalignments, or bearing failures. They play a crucial role in automotive applications for engine diagnostics and in aerospace for structural health monitoring. Unlike pressure sensors that measure force exerted by fluids, vibration sensors detect oscillatory motion, making them essential for ensuring equipment reliability and safety.

Common Applications of Pressure Sensors

Pressure sensors are widely used in automotive systems for monitoring tire pressure and engine performance, ensuring safety and efficiency. In industrial settings, they measure fluid and gas pressure in pipelines and machinery to maintain optimal operation and prevent equipment failure. Medical devices also rely on pressure sensors for monitoring blood pressure and respiratory functions, providing critical data for patient care.

Advantages and Limitations of Vibration Sensors

Vibration sensors offer precise detection of mechanical faults and early warning for equipment maintenance, enhancing your operational efficiency by reducing downtime. Their limitations include sensitivity to environmental noise and the need for proper calibration to ensure accurate readings. Compared to pressure sensors, vibration sensors excel in monitoring rotational and structural dynamics but are less effective in measuring fluid or gas pressure changes.

Advantages and Limitations of Pressure Sensors

Pressure sensors offer advantages such as high accuracy in measuring fluid, gas, and solid pressure, compact size for easy integration, and durability in harsh industrial environments. Their limitations include susceptibility to temperature variations affecting sensor accuracy, potential mechanical wear in moving parts, and limited suitability for dynamic vibration detection compared to vibration sensors. Optimizing pressure sensor applications requires careful consideration of operating conditions and calibration to ensure reliable performance.

Selection Criteria: Choosing Between Vibration and Pressure Sensors

Selecting between vibration and pressure sensors depends on the specific monitoring requirements of industrial equipment or processes. Vibration sensors are ideal for detecting mechanical anomalies, imbalance, or misalignment in rotating machinery, enabling predictive maintenance. Pressure sensors excel in measuring fluid or gas pressure levels, crucial for ensuring system safety and operational efficiency in pipelines, tanks, and hydraulic systems.

Future Trends in Vibration and Pressure Sensing Technology

Future trends in vibration and pressure sensing technology emphasize the integration of AI and IoT to enhance predictive maintenance and real-time data analytics. Innovations in MEMS (Micro-Electro-Mechanical Systems) are driving smaller, more accurate, and energy-efficient sensors that can be embedded in various industrial applications. Your systems will benefit from improved sensor fusion techniques, enabling comprehensive monitoring and smarter decision-making processes.

Vibration Sensor vs Pressure Sensor Infographic

electrown.com

electrown.com