Low voltage drives operate typically below 1,000 volts and are suited for smaller applications with less demanding power requirements, while medium voltage drives handle voltages from 1,000 to 15,000 volts for larger industrial processes requiring higher power efficiency and reduced energy loss. Explore the rest of the article to understand how selecting the right voltage drive can optimize your system's performance and reliability.

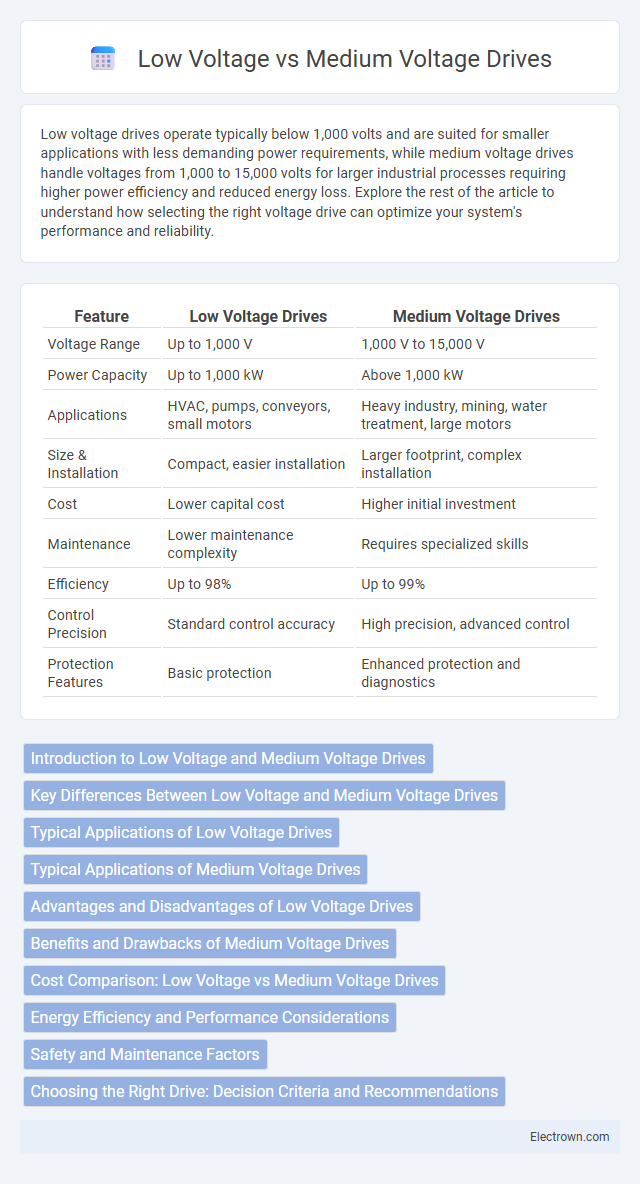

Table of Comparison

| Feature | Low Voltage Drives | Medium Voltage Drives |

|---|---|---|

| Voltage Range | Up to 1,000 V | 1,000 V to 15,000 V |

| Power Capacity | Up to 1,000 kW | Above 1,000 kW |

| Applications | HVAC, pumps, conveyors, small motors | Heavy industry, mining, water treatment, large motors |

| Size & Installation | Compact, easier installation | Larger footprint, complex installation |

| Cost | Lower capital cost | Higher initial investment |

| Maintenance | Lower maintenance complexity | Requires specialized skills |

| Efficiency | Up to 98% | Up to 99% |

| Control Precision | Standard control accuracy | High precision, advanced control |

| Protection Features | Basic protection | Enhanced protection and diagnostics |

Introduction to Low Voltage and Medium Voltage Drives

Low voltage drives typically operate at voltages below 1000V and are widely used for applications requiring precise motor control with smaller power demands. Medium voltage drives function within voltage ranges from 1000V to 6900V, enabling efficient performance in larger industrial processes where higher power and reduced harmonic distortion are critical. Understanding the differences in voltage classification, power handling, and application scope helps you select the optimal drive for your operational needs.

Key Differences Between Low Voltage and Medium Voltage Drives

Low voltage drives typically operate below 1,000 volts and are designed for applications requiring lower power levels, while medium voltage drives operate between 1,000 and 7,500 volts, supporting higher power demands and industrial-scale machinery. Key differences include their electrical insulation requirements, size, and installation costs, with medium voltage drives necessitating more robust cooling systems and safety measures. Your choice between the two impacts energy efficiency, maintenance complexity, and overall system reliability based on the specific voltage and power needs of your application.

Typical Applications of Low Voltage Drives

Low voltage drives are commonly used in applications such as HVAC systems, conveyors, and pump controls where power ratings typically range up to 690 volts. These drives offer precise motor control for small to medium-sized industrial machinery, enhancing energy efficiency and reducing operational costs. Your choice of a low voltage drive supports reliable performance in building automation, packaging, and material handling industries.

Typical Applications of Medium Voltage Drives

Medium voltage drives are commonly used in heavy industrial applications such as mining, oil and gas, water treatment, and large HVAC systems where power ratings range from 1,000 to 15,000 volts. These drives provide efficient control for large pumps, compressors, fans, and conveyors, improving energy savings and reducing mechanical stress on equipment. If your operation involves high-power machinery requiring precise speed control and reliability, medium voltage drives offer the robust solution needed for optimal performance.

Advantages and Disadvantages of Low Voltage Drives

Low voltage drives typically offer lower initial costs, simpler installation, and easier maintenance compared to medium voltage drives, making them ideal for small to medium-sized applications. However, they can generate higher harmonic distortion and are less efficient for high-power demands, potentially increasing operational costs over time. Your choice should balance these factors with the specific power requirements and space constraints of your system.

Benefits and Drawbacks of Medium Voltage Drives

Medium voltage drives offer significant benefits such as higher power capacity, improved efficiency, and reduced harmonic distortion, making them ideal for large industrial applications requiring robust performance. Their drawbacks include higher initial costs, increased complexity in installation and maintenance, and the need for specialized components and expertise. Understanding these factors helps you decide if medium voltage drives align with your operational needs and budget constraints.

Cost Comparison: Low Voltage vs Medium Voltage Drives

Low voltage drives typically have lower initial costs and simpler installation requirements compared to medium voltage drives, which require more robust infrastructure and specialized components. Medium voltage drives offer cost savings in high power applications by improving energy efficiency and reducing harmonic distortion, leading to lower operational expenses over time. Choosing between the two depends on balancing upfront investment against long-term operational savings and specific application power requirements.

Energy Efficiency and Performance Considerations

Low voltage drives typically operate below 1 kV and are favored for their cost-effectiveness and ease of integration in applications with moderate power requirements, offering reasonable energy efficiency for small to medium loads. Medium voltage drives, operating between 1 kV and 35 kV, deliver superior energy efficiency and performance in high-power industrial applications by minimizing losses and enabling precise motor control over larger capacity equipment. Selecting the appropriate drive voltage depends on application-specific factors such as load size, operational efficiency targets, and total cost of ownership.

Safety and Maintenance Factors

Low voltage drives typically operate under 1,000 volts, offering enhanced safety due to lower electrical hazards and simpler insulation requirements, making maintenance tasks less risky. Medium voltage drives, ranging from 1,000 to 35,000 volts, require more stringent safety protocols, specialized training, and advanced protective equipment to manage higher arc flash and electrical shock risks during maintenance. Proper maintenance of medium voltage drives demands regular insulation testing and adherence to industry standards such as IEEE and NFPA 70E to ensure safe operation and minimize downtime.

Choosing the Right Drive: Decision Criteria and Recommendations

Selecting the appropriate drive voltage level depends on application power requirements, load characteristics, and system efficiency goals. Low voltage drives (up to 1000V) are ideal for small to medium horsepower motors offering cost-effectiveness and ease of installation, while medium voltage drives (above 1000V to 15kV) suit high-power industrial processes requiring greater reliability and reduced harmonic distortion. Decision criteria should prioritize factors such as motor size, operational environment, initial investment, maintenance capabilities, and energy consumption to optimize performance and lifecycle costs.

Low Voltage vs Medium Voltage Drives Infographic

electrown.com

electrown.com