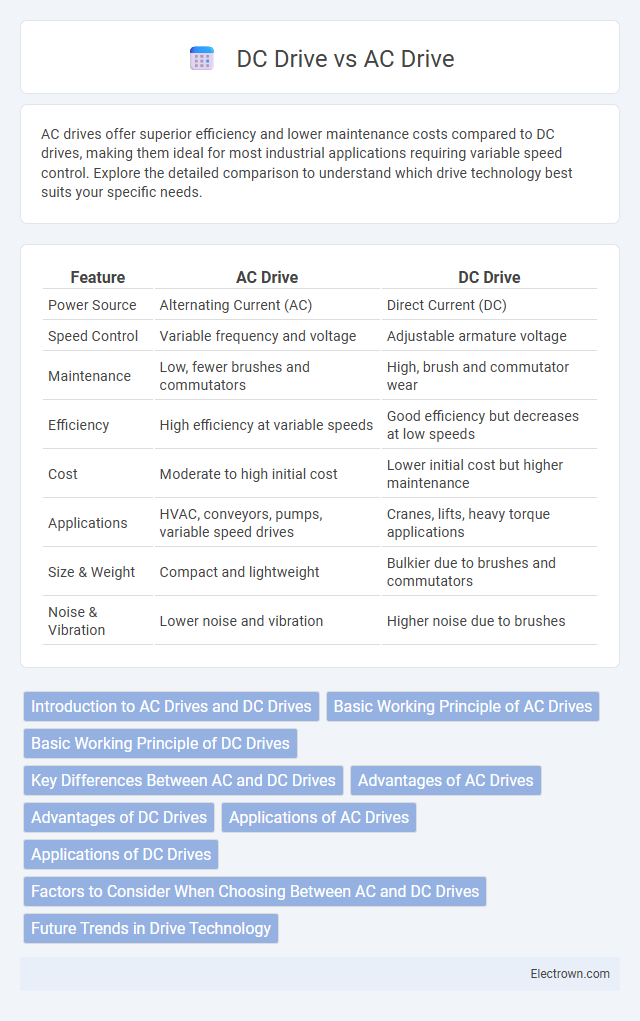

AC drives offer superior efficiency and lower maintenance costs compared to DC drives, making them ideal for most industrial applications requiring variable speed control. Explore the detailed comparison to understand which drive technology best suits your specific needs.

Table of Comparison

| Feature | AC Drive | DC Drive |

|---|---|---|

| Power Source | Alternating Current (AC) | Direct Current (DC) |

| Speed Control | Variable frequency and voltage | Adjustable armature voltage |

| Maintenance | Low, fewer brushes and commutators | High, brush and commutator wear |

| Efficiency | High efficiency at variable speeds | Good efficiency but decreases at low speeds |

| Cost | Moderate to high initial cost | Lower initial cost but higher maintenance |

| Applications | HVAC, conveyors, pumps, variable speed drives | Cranes, lifts, heavy torque applications |

| Size & Weight | Compact and lightweight | Bulkier due to brushes and commutators |

| Noise & Vibration | Lower noise and vibration | Higher noise due to brushes |

Introduction to AC Drives and DC Drives

AC drives regulate the speed and torque of alternating current motors by adjusting the frequency and voltage supplied to the motor, providing energy-efficient and precise motor control in industrial applications. DC drives control the speed and torque of direct current motors by varying the armature voltage or field current, enabling smooth acceleration and reliable performance in processes requiring high starting torque. Your choice between AC and DC drives depends on factors like motor type, application requirements, and control precision.

Basic Working Principle of AC Drives

AC drives control electric motor speed and torque by varying the frequency and voltage of the power supplied to the motor. These drives use a rectifier to convert incoming AC power to DC, followed by an inverter that generates a variable frequency AC output. Advanced pulse-width modulation (PWM) techniques in AC drives ensure precise motor control and energy efficiency for various industrial applications.

Basic Working Principle of DC Drives

DC drives operate by controlling the voltage applied to a DC motor, adjusting the armature current to regulate speed and torque precisely. The basic working principle involves converting AC power to DC through a rectifier, then using a controller to vary the voltage supplied to the motor. Your choice of a DC drive ensures smooth acceleration, high starting torque, and accurate speed control in applications requiring dynamic performance.

Key Differences Between AC and DC Drives

AC drives use alternating current to control the speed and torque of electric motors, offering higher efficiency and lower maintenance compared to DC drives. DC drives rely on direct current and provide precise speed control with high starting torque but require more maintenance due to brushes and commutators. The key differences include motor construction, control complexity, energy efficiency, and application suitability in industries like manufacturing and automation.

Advantages of AC Drives

AC drives offer superior energy efficiency by precisely controlling motor speed and torque, reducing power consumption in various industrial applications. They provide smoother operation with less mechanical stress, enhancing the lifespan of motors and connected equipment. Advanced AC drive technology supports regenerative braking, enabling energy recovery and further operational cost savings.

Advantages of DC Drives

DC drives offer precise speed control and high starting torque, making them ideal for applications requiring variable speed and heavy-load starting conditions. Their excellent torque-speed characteristics provide smooth acceleration and deceleration, enhancing process accuracy and equipment lifespan. Your choice of DC drive ensures efficient performance in industries such as manufacturing, mining, and material handling where dynamic load changes are common.

Applications of AC Drives

AC drives are widely used in applications requiring precise speed control and energy efficiency, such as HVAC systems, conveyor belts, and pumps. Their ability to handle variable frequency and voltage makes them ideal for industrial automation, robotics, and electric vehicle motor control. You can optimize performance and reduce maintenance costs by choosing AC drives for processes involving frequent start-stop cycles and variable torque demands.

Applications of DC Drives

DC drives are commonly used in applications requiring precise speed control and high starting torque, such as in elevators, electric vehicles, and cranes. Their ability to provide smooth acceleration and deceleration makes them ideal for rolling mills, printing machines, and paper mills. Industrial processes involving variable load and frequent start-stop operations benefit significantly from the robust performance of DC drives.

Factors to Consider When Choosing Between AC and DC Drives

When choosing between AC and DC drives, consider factors such as torque requirements, control precision, and maintenance needs. AC drives offer better efficiency and lower maintenance due to fewer components, while DC drives excel in providing high starting torque and smooth speed control. Your decision should align with the specific application demands, environmental conditions, and cost constraints.

Future Trends in Drive Technology

Future trends in drive technology highlight the rapid advancements in AC drives due to their higher efficiency, lower maintenance, and superior control capabilities compared to DC drives. The integration of smart sensors and IoT connectivity will enhance predictive maintenance and optimize energy consumption in AC drive systems. Your industrial applications can benefit significantly from these innovations, offering improved performance and reduced operational costs.

AC Drive vs DC Drive Infographic

electrown.com

electrown.com