Soft starters reduce the initial inrush current and mechanical stress on motors by gradually ramping up voltage, while Variable Frequency Drives (VFDs) control both voltage and frequency to provide precise motor speed and torque control. Explore the rest of the article to understand which solution best fits your application and how to optimize motor performance effectively.

Table of Comparison

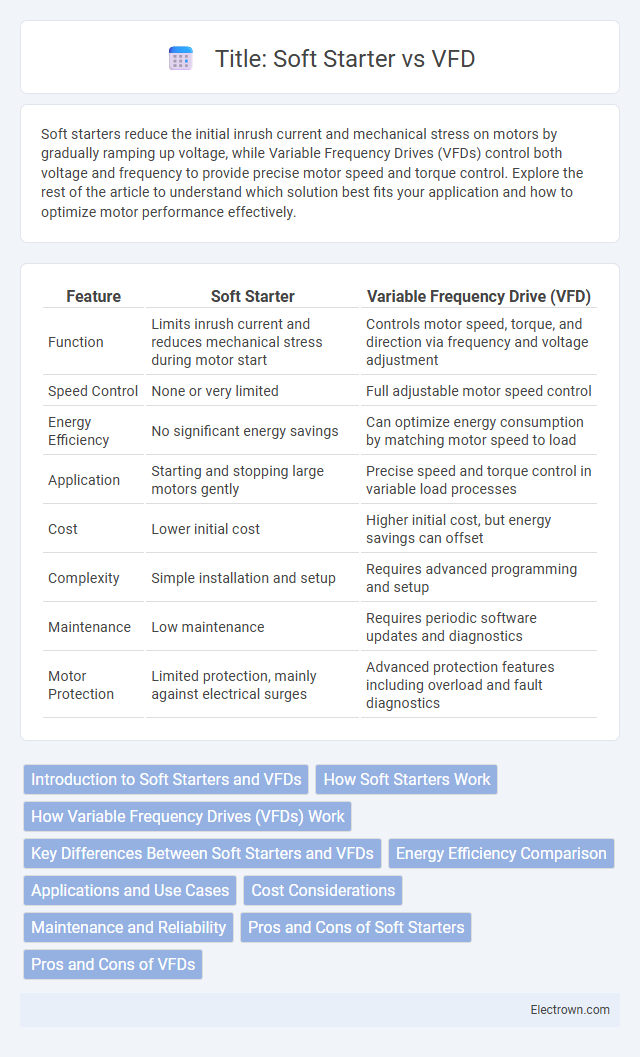

| Feature | Soft Starter | Variable Frequency Drive (VFD) |

|---|---|---|

| Function | Limits inrush current and reduces mechanical stress during motor start | Controls motor speed, torque, and direction via frequency and voltage adjustment |

| Speed Control | None or very limited | Full adjustable motor speed control |

| Energy Efficiency | No significant energy savings | Can optimize energy consumption by matching motor speed to load |

| Application | Starting and stopping large motors gently | Precise speed and torque control in variable load processes |

| Cost | Lower initial cost | Higher initial cost, but energy savings can offset |

| Complexity | Simple installation and setup | Requires advanced programming and setup |

| Maintenance | Low maintenance | Requires periodic software updates and diagnostics |

| Motor Protection | Limited protection, mainly against electrical surges | Advanced protection features including overload and fault diagnostics |

Introduction to Soft Starters and VFDs

Soft starters gradually increase the voltage supplied to electric motors, reducing inrush current and mechanical stress during startup, ideal for applications requiring smooth acceleration. Variable Frequency Drives (VFDs) control motor speed by adjusting the frequency and voltage of the power supply, allowing for precise speed regulation and energy savings in diverse industrial processes. Both devices enhance motor performance but serve distinct purposes: soft starters optimize starting conditions while VFDs provide comprehensive speed and torque control.

How Soft Starters Work

Soft starters regulate motor startup by gradually increasing voltage, reducing inrush current and mechanical stress on electrical systems. They employ thyristor technology to control the initial voltage supplied to the motor, allowing a smooth acceleration without abrupt torque changes. This method minimizes the risk of electrical faults and extends motor and equipment lifespan compared to direct-on-line starting.

How Variable Frequency Drives (VFDs) Work

Variable Frequency Drives (VFDs) regulate motor speed by adjusting the frequency and voltage of the electrical supply, allowing precise control over motor performance and energy consumption. Unlike soft starters that mainly reduce inrush current during startup, VFDs enable continuous speed variation and torque control throughout operation. Your system's efficiency and lifespan improve significantly with VFDs due to smoother acceleration, deceleration, and optimized motor load management.

Key Differences Between Soft Starters and VFDs

Soft starters gradually ramp up voltage to reduce inrush current and mechanical stress during motor startup, primarily offering controlled acceleration without changing motor speed. Variable Frequency Drives (VFDs) adjust both voltage and frequency, enabling precise speed control and energy savings throughout motor operation. Your choice depends on whether you need simple startup protection or full speed control and efficiency management.

Energy Efficiency Comparison

Soft starters reduce initial inrush current to motors, leading to lower mechanical stress but provide limited energy savings during continuous operation compared to Variable Frequency Drives (VFDs). VFDs offer precise motor speed control by adjusting frequency and voltage, significantly enhancing energy efficiency, especially in applications with variable load demands. Studies indicate that VFDs can achieve energy savings of up to 30-50% over soft starters by optimizing motor performance throughout the operational cycle.

Applications and Use Cases

Soft starters are ideal for applications requiring reduced starting current and torque, such as pumps, conveyors, and fans, where smooth acceleration is essential to prevent mechanical stress. Variable Frequency Drives (VFDs) offer precise speed control and energy efficiency, making them suitable for complex applications like HVAC systems, centrifugal pumps, and elevators that demand variable speed operation and process optimization. VFDs enable energy savings in variable torque loads, while soft starters primarily focus on mitigating inrush current during motor startup in constant-speed applications.

Cost Considerations

Soft starters generally have lower upfront costs compared to Variable Frequency Drives (VFDs), making them a budget-friendly option for applications requiring simple motor starting and stopping. VFDs, while more expensive initially, provide greater energy savings and process control by adjusting motor speed, potentially reducing long-term operational costs. Your choice should consider both initial investment and anticipated energy efficiency to optimize overall cost-effectiveness.

Maintenance and Reliability

Soft starters require less frequent maintenance due to simpler control components and fewer wearing parts, enhancing overall reliability in moderate-start applications. Variable Frequency Drives (VFDs) offer advanced motor protection features and precise speed control but may demand more regular maintenance because of complex electronics and cooling systems. Choosing between soft starters and VFDs depends on balancing the need for maintenance resources with desired operational control and system reliability.

Pros and Cons of Soft Starters

Soft starters provide smooth motor startup by gradually increasing voltage, reducing mechanical stress and electrical peak currents, which extends equipment lifespan and lowers maintenance costs. They are simpler, cost-effective, and easier to install compared to variable frequency drives (VFDs), but lack precise speed control and energy-saving capabilities during operation. The main limitation lies in their inability to adjust motor speed continuously, making them less suitable for applications requiring variable torque or speed regulation.

Pros and Cons of VFDs

Variable Frequency Drives (VFDs) offer precise motor speed control, leading to significant energy savings and reduced mechanical stress, which prolongs equipment lifespan. They can handle a wide range of speeds and provide soft starting and stopping to minimize wear. However, VFDs come with a higher initial cost, increased complexity, and may require additional maintenance and electromagnetic interference (EMI) mitigation measures.

Soft Starter vs VFD Infographic

electrown.com

electrown.com