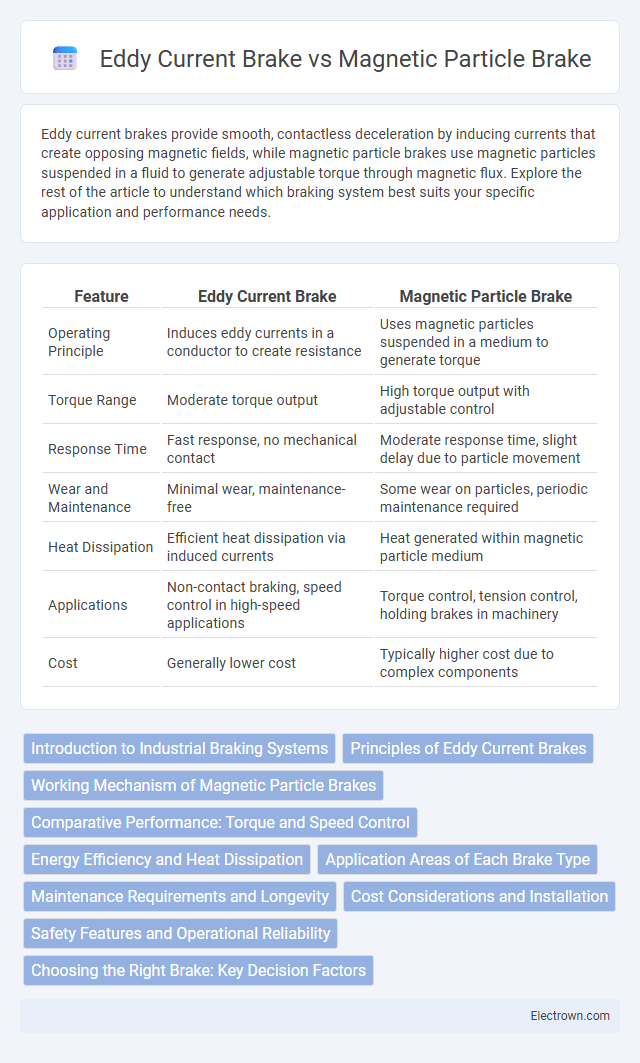

Eddy current brakes provide smooth, contactless deceleration by inducing currents that create opposing magnetic fields, while magnetic particle brakes use magnetic particles suspended in a fluid to generate adjustable torque through magnetic flux. Explore the rest of the article to understand which braking system best suits your specific application and performance needs.

Table of Comparison

| Feature | Eddy Current Brake | Magnetic Particle Brake |

|---|---|---|

| Operating Principle | Induces eddy currents in a conductor to create resistance | Uses magnetic particles suspended in a medium to generate torque |

| Torque Range | Moderate torque output | High torque output with adjustable control |

| Response Time | Fast response, no mechanical contact | Moderate response time, slight delay due to particle movement |

| Wear and Maintenance | Minimal wear, maintenance-free | Some wear on particles, periodic maintenance required |

| Heat Dissipation | Efficient heat dissipation via induced currents | Heat generated within magnetic particle medium |

| Applications | Non-contact braking, speed control in high-speed applications | Torque control, tension control, holding brakes in machinery |

| Cost | Generally lower cost | Typically higher cost due to complex components |

Introduction to Industrial Braking Systems

Industrial braking systems incorporate Eddy Current Brakes, which use electromagnetic induction to create non-contact braking forces, offering wear-free operation and precise speed control. Magnetic Particle Brakes utilize magnetic particles within a magnetic field to transmit torque through adjustable friction, providing high torque density and smooth engagement. Both systems are essential in applications requiring reliable, maintenance-free braking with rapid response times in manufacturing and automation industries.

Principles of Eddy Current Brakes

Eddy current brakes operate on the principle of electromagnetic induction, where a magnetic field induces circular electrical currents (eddy currents) in a conductive disc or drum, generating resistance that slows motion without physical contact. This non-contact braking system provides smooth and silent deceleration while minimizing wear and maintenance. Understanding these principles helps you evaluate the efficiency and application suitability of eddy current brakes compared to magnetic particle brakes.

Working Mechanism of Magnetic Particle Brakes

Magnetic particle brakes operate by applying a magnetic field to a chamber filled with ferromagnetic particles, which increases resistance between the input and output shafts proportionally to the field strength. This controlled friction allows precise torque regulation for applications requiring consistent braking or tension control. Your choice of a magnetic particle brake ensures smooth, adjustable braking force without physical contact, reducing wear and enabling long service life.

Comparative Performance: Torque and Speed Control

Eddy Current Brakes deliver smooth, contactless torque with high-speed capability, offering precise speed control in dynamic applications. Magnetic Particle Brakes provide higher torque density and superior holding torque at low speeds, ensuring stable performance under variable loads. Both brake types excel in different operational ranges, with Eddy Current Brakes optimized for high-speed modulation and Magnetic Particle Brakes favored for high-torque, low-speed control.

Energy Efficiency and Heat Dissipation

Eddy current brakes offer high energy efficiency by generating resistive forces through magnetic fields without mechanical contact, minimizing wear and energy loss. Magnetic particle brakes dissipate energy more effectively via heat generated in the magnetic particles, but this results in higher thermal buildup requiring robust cooling systems. Both systems optimize heat dissipation differently, with eddy current brakes relying on non-contact induction and magnetic particle brakes on controlled particle friction, influencing their performance in energy-intensive applications.

Application Areas of Each Brake Type

Eddy current brakes excel in high-speed rail systems and roller coasters where smooth, contactless braking is crucial, offering rapid response and minimal wear. Magnetic particle brakes are ideal for industrial machinery, such as tension control in web processing and dynamometers, due to their precise torque control and adjustable braking force. You can select the appropriate brake based on your specific application, whether it demands non-contact high-speed deceleration or adjustable mechanical resistance.

Maintenance Requirements and Longevity

Eddy current brakes require minimal maintenance due to their contactless operation, which eliminates wear and extends their lifespan significantly. Magnetic particle brakes involve friction components that necessitate regular inspection and replacement of particles and linings to maintain optimal performance. Your choice between these braking systems should consider the balance between maintenance demands and long-term durability for your specific application.

Cost Considerations and Installation

Eddy Current Brakes generally have lower initial costs and simpler installation processes due to fewer components and absence of consumables. Magnetic Particle Brakes often require higher upfront investment, reflecting their complex assembly and the need for periodic maintenance of magnetic particles. Installation of Magnetic Particle Brakes demands precise alignment and more space, increasing labor expenses compared to the more compact and straightforward Eddy Current Brake setup.

Safety Features and Operational Reliability

Eddy Current Brakes provide high safety through non-contact braking, eliminating wear and reducing heat generation, which enhances operational reliability in continuous applications. Magnetic Particle Brakes offer precise torque control with built-in fail-safe mechanisms, ensuring consistent performance even under high load conditions. Both braking systems incorporate temperature sensors and robust housings to prevent overheating and mechanical failure, maximizing safety and durability in industrial environments.

Choosing the Right Brake: Key Decision Factors

Selecting between an Eddy Current Brake and a Magnetic Particle Brake depends primarily on your application's torque control, response time, and heat dissipation needs. Eddy Current Brakes offer smooth, contactless operation ideal for high-speed deceleration but generate less torque compared to Magnetic Particle Brakes, which deliver higher torque and better heat handling due to friction-based resistance. Evaluating your system's required braking torque, thermal management, and maintenance preferences will ensure you choose the most efficient and reliable braking solution.

Eddy Current Brake vs Magnetic Particle Brake Infographic

electrown.com

electrown.com